A device that automatically adjusts the number of shims according to the height of the tool tip

An automatic height adjustment technology, applied in the direction of turning equipment, toolholder accessories, metal processing equipment, etc., can solve the problems of large machining errors, lower work efficiency, and high experience requirements, so as to reduce the possibility of errors and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

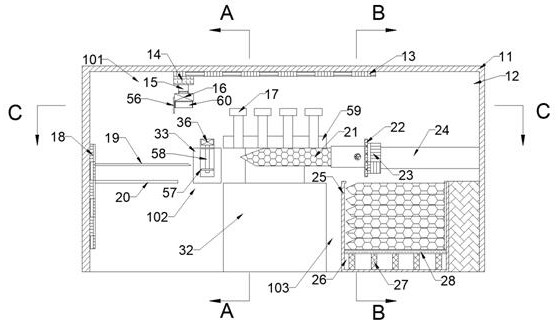

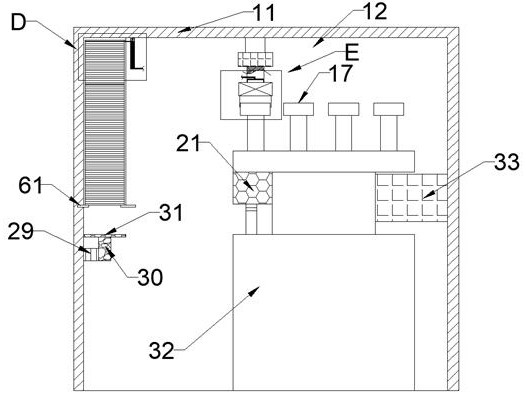

[0018] Bonded below Figure 1-6 The present invention will be described in detail, in which it is convenient for the description, the orientation of the following statement is as follows: The above-mentioned left and right directions figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0019] An apparatus, which is automatically adjusted according to the height of the knife tip, including a working chamber 12, and a working chamber 12 provided in the working chamber 12, and the working chamber 12 Secondary electric slide rail 24 is fixed, and the front and rear end faces of the two first electric rails 24 are provided with a second electric slide rail 23, and the second electric slide rail 23 is slidably provided with a third electric. Slide rail 22, the third electric slide rail 22 is slid on the front side surface of the upper left end side, and the mounting motor 43 is provided with a worm 42, and the mounting worm 42 is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com