Continuous production process of cellulose sponge

A cellulose sponge and production process technology, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of uneven heating of raw materials, difficulty in collecting and processing waste gas and waste liquid, and difficult shaping of viscose solution, so as to achieve guaranteed performance Stability, realization of waste utilization, and the effect of being friendly to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

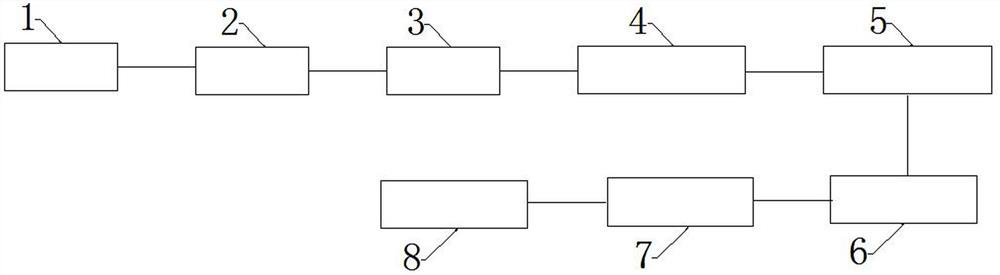

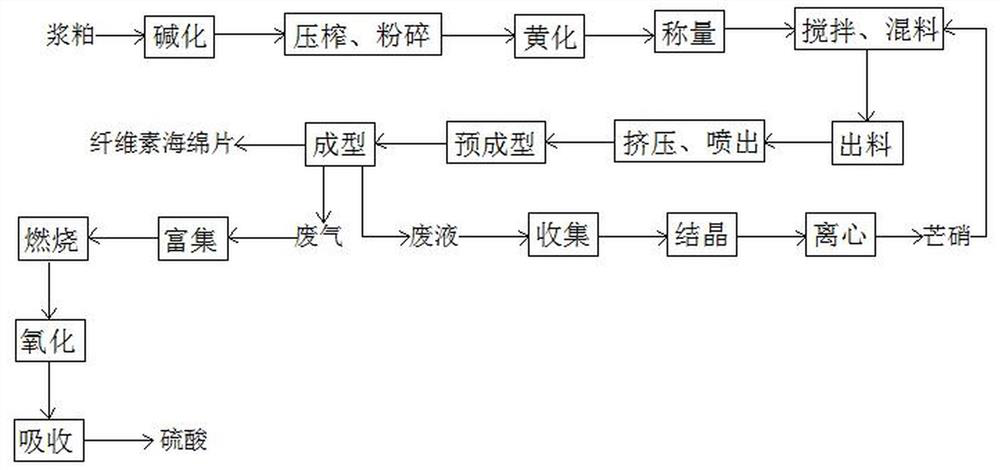

[0070] A continuous production process of cellulose sponge, comprising the steps of:

[0071] A. Glue making: use pulp with methylcellulose content ≥ 93% and dynamic viscosity ≥ 10mpa.s as raw material, soak in dipping tank 1 for alkalization, press 2 for crushing, and yellowing machine 3 for vacuum yellowing to obtain viscose ; Wherein, in yellowing machine 3, CS2 addition ratio is 38%, and vacuum degree is-0.085MPa;

[0072] B. Weighing: with the ratio of Glauber's salt to the obtained viscose as 3.2, weigh Glauber's salt and the obtained viscose respectively; wherein, the particle size of Glauber's salt is 2mm;

[0073] C. Stirring: place the weighed Glauber's salt and the obtained viscose in the crankshaft mixer 4, and stir for 15 minutes under the conditions of a rotating speed of 60r / min and a temperature of ≤40°C to obtain a mixture;

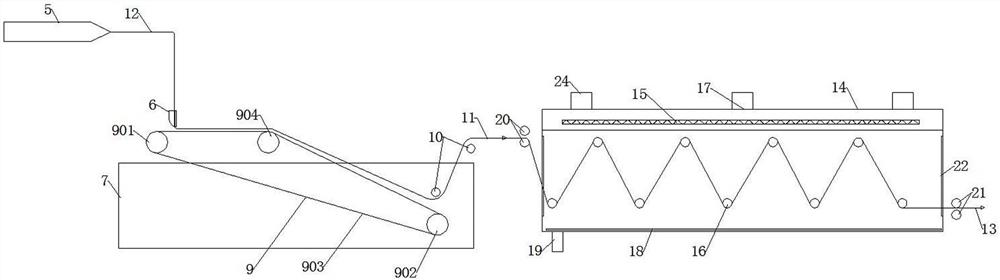

[0074] D. Discharging: Place the obtained mixed material in the mixing hopper on the screw extruder 5, open the screw extruder 5, a...

Embodiment 2

[0080] Based on embodiment 1, the difference of this embodiment is:

[0081] A continuous production process of cellulose sponge, comprising the steps of:

[0082] A. Glue making: use pulp with methylcellulose content ≥ 93% and dynamic viscosity ≥ 10mpa.s as raw material, soak in dipping tank 1 for alkalization, press 2 for crushing, and yellowing machine 3 for vacuum yellowing to obtain viscose ; Wherein, in yellowing machine 3, CS2 adding ratio is 33%, and vacuum degree is-0.08MPa;

[0083] B. Weighing: Take the ratio of Glauber's salt to the obtained viscose as 2.9, weigh Glauber's salt and the obtained viscose respectively; wherein, the particle size of Glauber's salt is 5mm;

[0084] C. Stirring: place the weighed Glauber's salt and the obtained viscose in the crankshaft mixer 4, and stir for 10 minutes at a speed of 30r / min and a temperature of ≤40°C to obtain a mixture;

[0085] D. Discharging: Place the mixed material obtained in the mixing hopper on the screw extr...

Embodiment 1-2

[0091] Based on Embodiment 1-2, the difference of this embodiment is:

[0092] A continuous production process of cellulose sponge, comprising the steps of:

[0093] A. Glue making: use pulp with methylcellulose content ≥ 93% and dynamic viscosity ≥ 10mpa.s as raw material, soak in dipping tank 1 for alkalization, press 2 for crushing, and yellowing machine 3 for vacuum yellowing to obtain viscose ; Wherein, in yellowing machine 3, CS2 addition ratio is 45%, and vacuum degree is-0.09MPa;

[0094] B. Weighing: Take the ratio of Glauber's salt to the obtained viscose as 3.5, weigh Glauber's salt and the obtained viscose respectively; wherein, the particle size of Glauber's salt is 3mm;

[0095] C. Stirring: Place the weighed Glauber's salt and the obtained viscose in the crankshaft mixer 4, and stir for 20 minutes under the condition that the rotating speed is 90r / min and the temperature is ≤40°C to obtain the mixture;

[0096] D. Discharging: Place the obtained mixed mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com