Liquid-gas two-phase medium coupling partition blowing sintering method and blowing device

A technology of injection device and sintering method, which is applied in the field of liquid-gas two-phase medium coupling partition injection sintering, liquid-gas two-phase medium coupling partition injection device, and injection sintering field, which can solve the problems of insufficient combustion energy and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

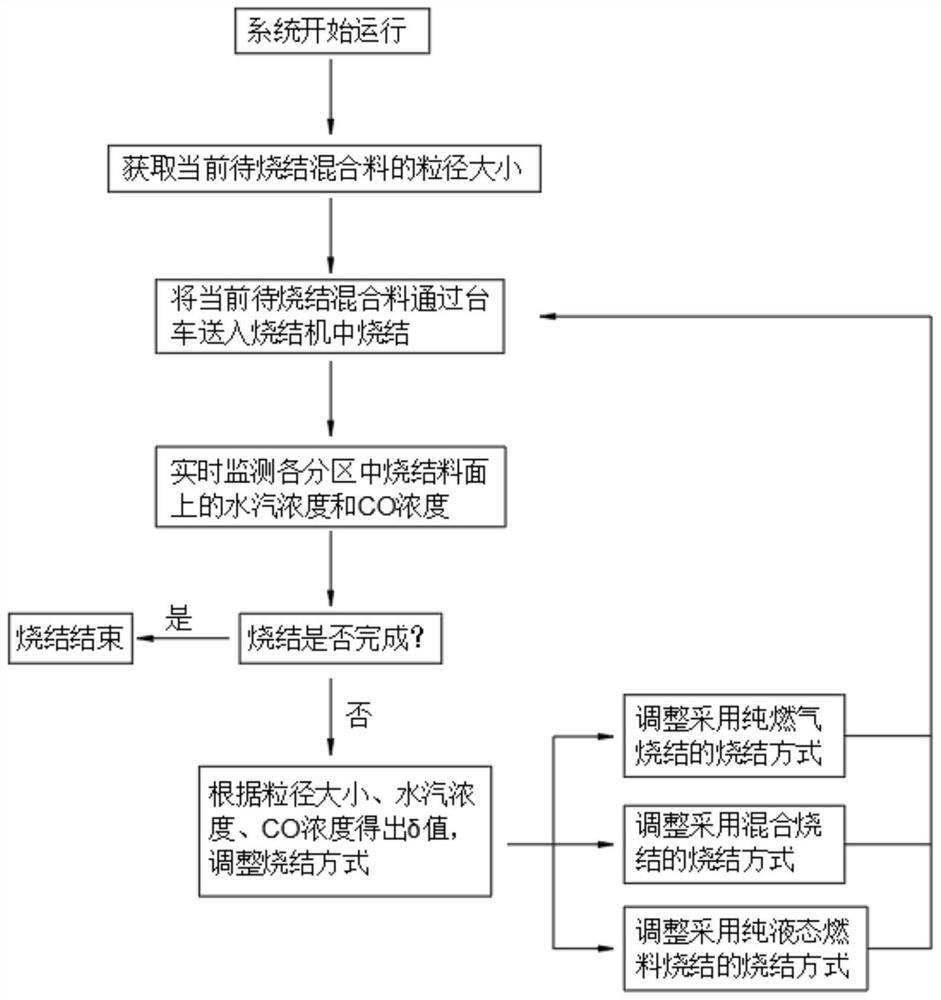

[0094] According to the first embodiment of the present invention, a liquid-gas two-phase medium coupling partition injection sintering method is provided:

[0095] A liquid-gas two-phase medium coupling partition injection sintering method, the method includes the following steps: 1) obtaining the particle size D of the current mixed material to be sintered; 2) sending the mixed material to be sintered into a sintering machine through a trolley for sintering , spraying gaseous fuel and liquid fuel to the material surface of the trolley in the form of partitions; 3) real-time monitoring when the mixture to be sintered is sintered on the trolley, to obtain the water vapor volume concentration C on the sintered material surface in each partition 水 and CO volume concentration C CO ; 4) according to step 1) and step 3) data D, C 水 、C CO , compare it with the historical average data stored in the system, so that one of the injection sintering methods of pure gaseous fuel sinterin...

Embodiment 1

[0129] According to the first embodiment of the present invention, a liquid-gas two-phase medium coupling partition injection sintering method is provided:

[0130] A liquid-gas two-phase medium coupling partition injection sintering method, the method includes the following steps: 1) obtaining the particle size D of the current mixed material to be sintered; 2) sending the mixed material to be sintered into a sintering machine through a trolley for sintering , spraying gaseous fuel and liquid fuel to the material surface of the trolley in the form of partitions; 3) real-time monitoring when the mixture to be sintered is sintered on the trolley, to obtain the water vapor volume concentration C on the sintered material surface in each partition 水 and CO volume concentration C CO ; 4) according to step 1) and step 3) data D, C 水 、C CO , compare it with the historical average data stored in the system, so that one of the injection sintering methods of pure gaseous fuel sinterin...

Embodiment 2

[0132] Repeat embodiment 1, just step 4) in data D, C 水 、C CO Substitute into formula (1) to obtain the judgment parameter δ of each partition above the trolley;

[0133]

[0134] Judging the size of δ, choose the injection sintering method:

[0135] When δ≤1, the sintering method of pure gaseous fuel injection sintering is adopted;

[0136] When 1<δ≤2, the sintering method of mixed injection sintering is adopted;

[0137] When δ>2, the sintering method of pure liquid fuel injection sintering is adopted;

[0138] Among them, D, C 水 、C CO The units are mm, %, %; D 平均 is the historical average particle size of the mixture to be sintered, mm; C 水平均 is the historical average volume concentration of water vapor during sintering, %; C CO平均 is the historical average volume concentration of CO during sintering, %; k1 is the particle size coupling coefficient, which takes a value of 0.7; k2 is the water vapor concentration coupling coefficient, which takes a value of 0.5; k3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com