Replaceable hollow double-wall concrete-filled steel tube prefabricated assembled pier

A double-wall steel pipe, prefabricated assembly technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of long maintenance period, large on-site workload, environmental traffic impact, etc., and achieves simple construction method, convenient operation, and rapid replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

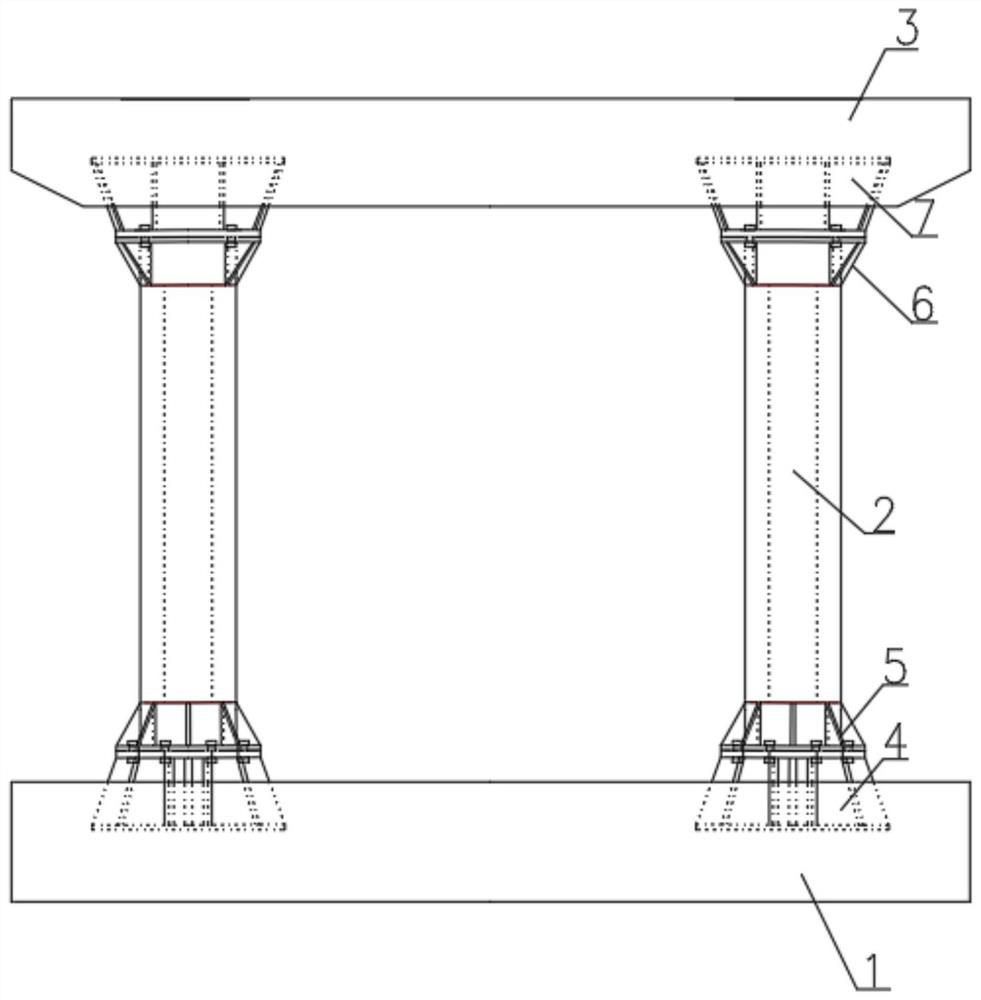

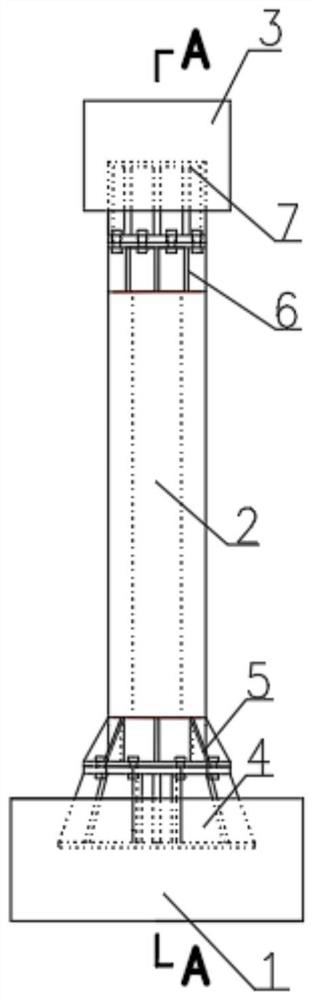

[0066] See Figure 1 to Figure 9 As shown, this embodiment proposes a replaceable hollow double-walled steel pipe concrete 22 prefabricated assembled bridge pier, including a cap 1, a prefabricated pier column 2 arranged on the cap, and a cover beam 3 arranged on the prefabricated pier column 2 , The bearing platform 1, the prefabricated pier column 2 and the cover beam 3 are sequentially connected by flanges to form a whole.

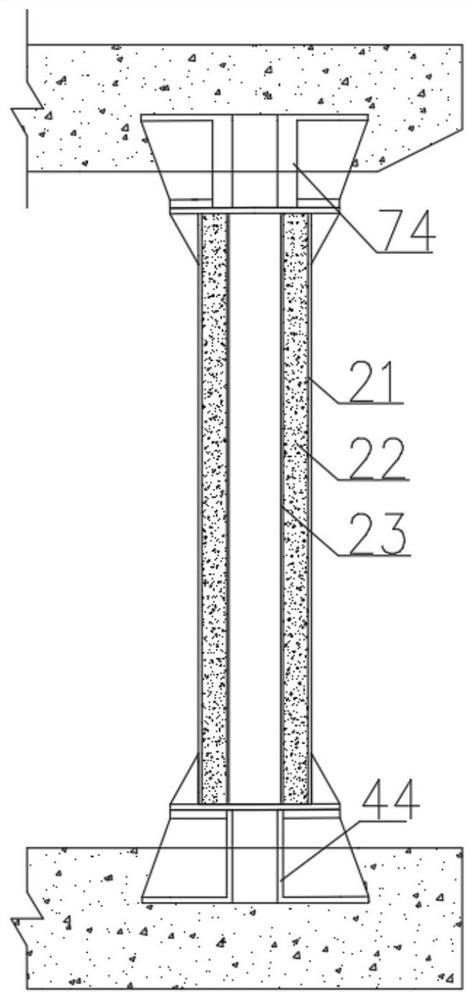

[0067] see you again Figure 2 to Figure 3 As shown, the prefabricated pier column 2 is composed of an inner steel pipe 23, an outer steel pipe 21 sleeved outside the inner steel pipe 23, and a concrete 22 poured between the inner steel pipe 23 and the outer steel pipe 21, wherein the inner steel pipe 23 and the outer steel pipe 21 The central axis coincides. Concrete 22 adopts existing conventional concrete 22 with properties such as ultra-high strength.

[0068] see you again Figure 4 to Figure 5 As shown, the top of the prefabricated pier column...

Embodiment 2

[0078] See Figure 10 to Figure 17As shown, this embodiment proposes a replaceable hollow double-walled steel pipe concrete 22 prefabricated assembled bridge pier, including a cap 1, a prefabricated pier column 2 arranged on the cap, and a cover beam 3 arranged on the prefabricated pier column 2 , The bearing platform 1, the prefabricated pier column 2 and the cover beam 3 are sequentially connected by flanges to form a whole.

[0079] see you again Figure 11 As shown, the prefabricated pier column 2 is composed of an inner steel pipe 23, an outer steel pipe 21 sleeved outside the inner steel pipe 23, and a concrete 22 poured between the inner steel pipe 23 and the outer steel pipe 21, wherein the inner steel pipe 23 and the outer steel pipe 21 The central axis coincides. Concrete 22 adopts existing conventional concrete 22 with properties such as ultra-high strength.

[0080] see you again Figure 12 to Figure 14 As shown, the top of the prefabricated pier column 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com