H-shaped steel overturning mechanism

A technology of turning mechanism and H-beam, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated and complicated operation steps, low production efficiency, complicated process, etc., and achieve labor saving and high operation efficiency. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

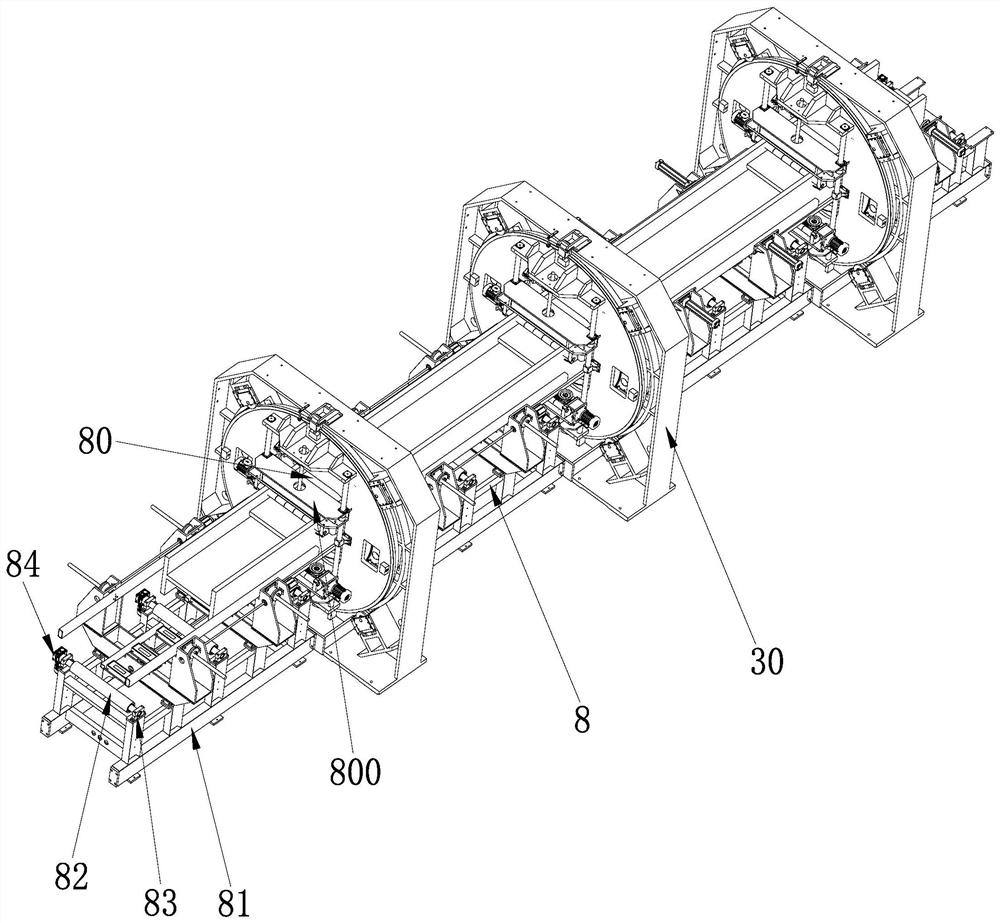

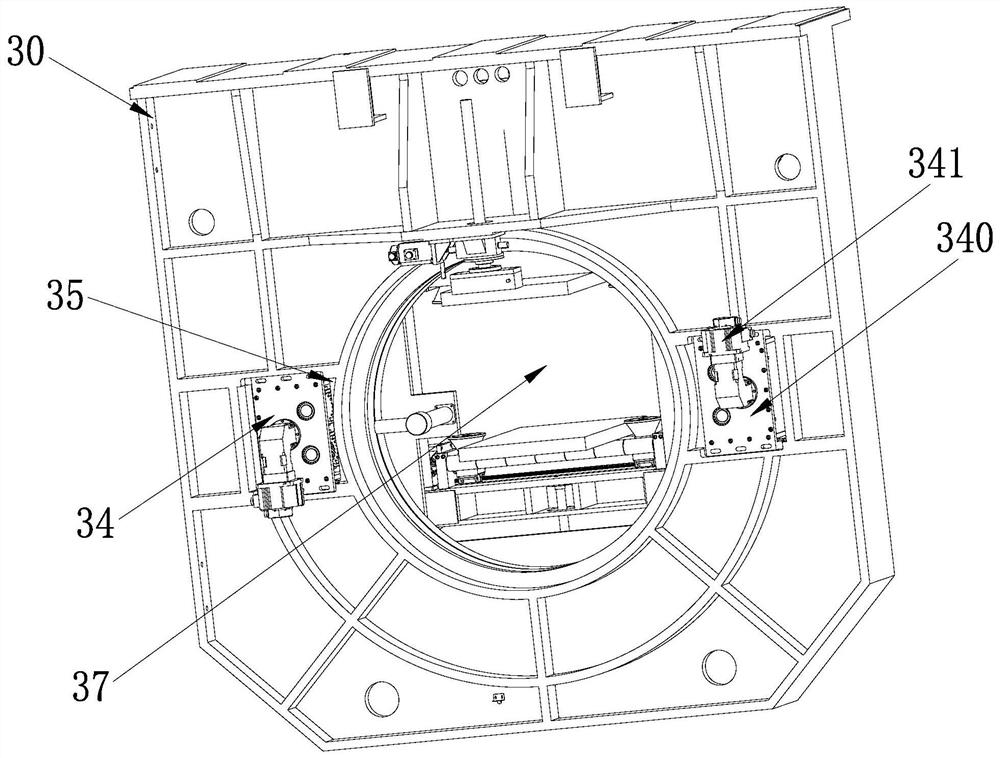

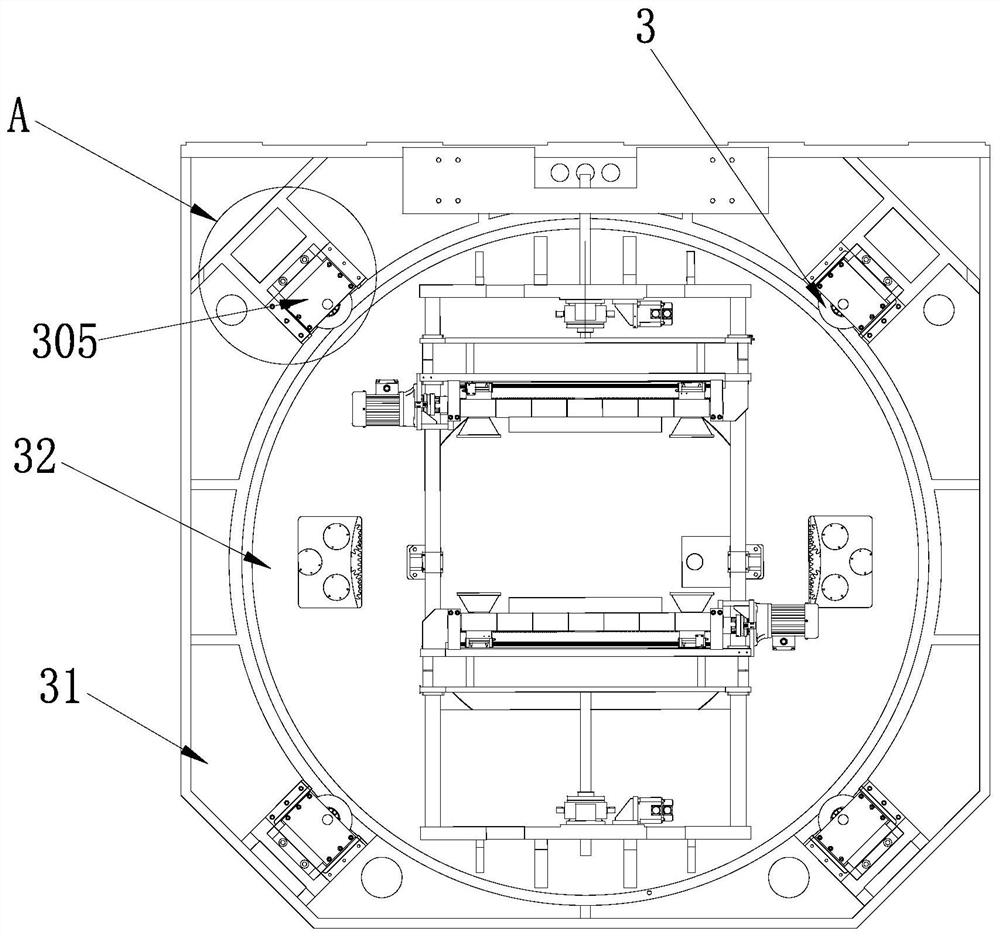

[0042] Example: as Figure 1-9 As shown, an H-shaped steel turning mechanism includes a plurality of H-shaped steel conveying mechanisms 8 and at least two turning mechanisms 30; two turning mechanisms 30 are arranged at intervals with a plurality of H-shaped steel conveying mechanisms 8; the turning mechanism 30 includes a base 31 and a rotary disc 32; the middle part of the base 31 is formed with a feeding port 37, and a rotary gear 33 is arranged inside the feeding port 37, and the rotary disc 32 is fixed on the rotary gear 33; 8 matching feed port 80, the feed port 80 communicates with the feed port 37; the base 31 is provided with at least one driving mechanism 34 for driving the rotary gear 33 to rotate; The clamping device 800 for holding the steel plate; the driving mechanism 34 drives the rotary gear 33 to rotate, and then drives the rotary plate 32 to rotate; the present invention uses at least two turning mechanisms and a plurality of H-shaped steel conveying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com