A kind of steel pipe surface derusting device for construction engineering

A technology for construction engineering and steel pipes, which is used in grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc. Provide work efficiency, increase friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

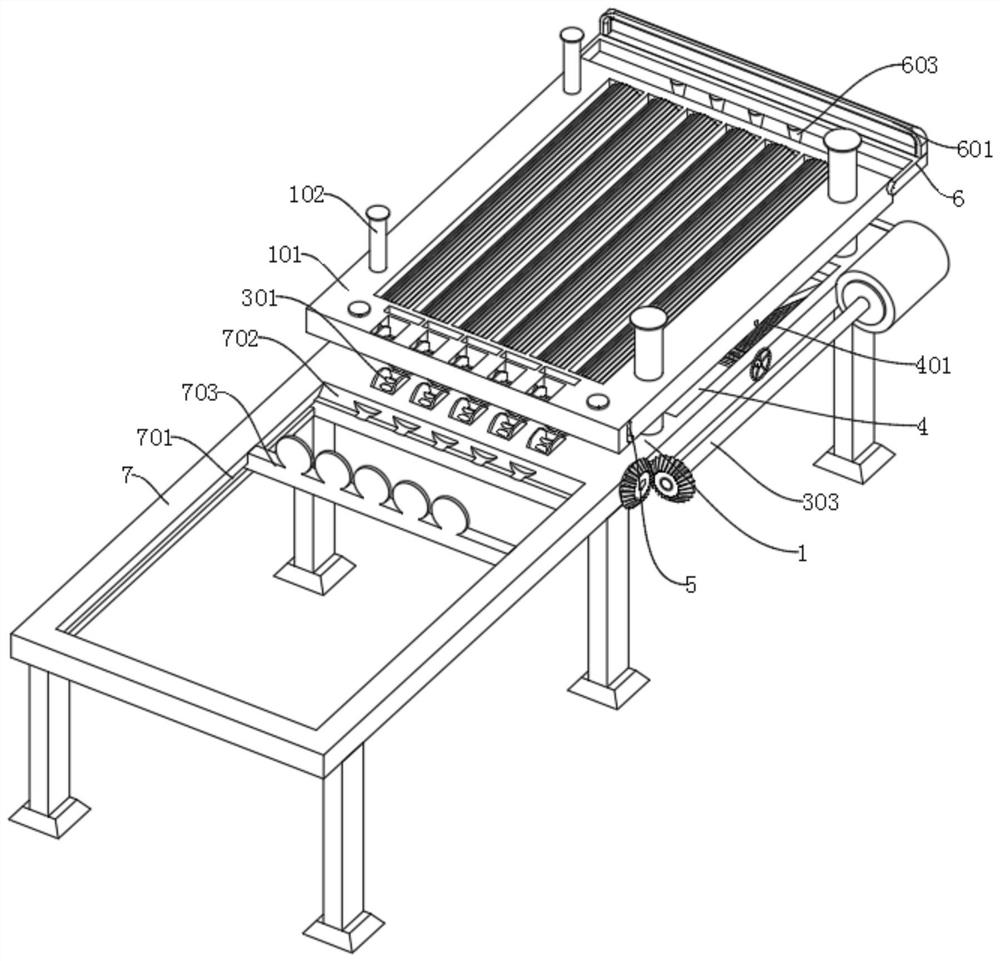

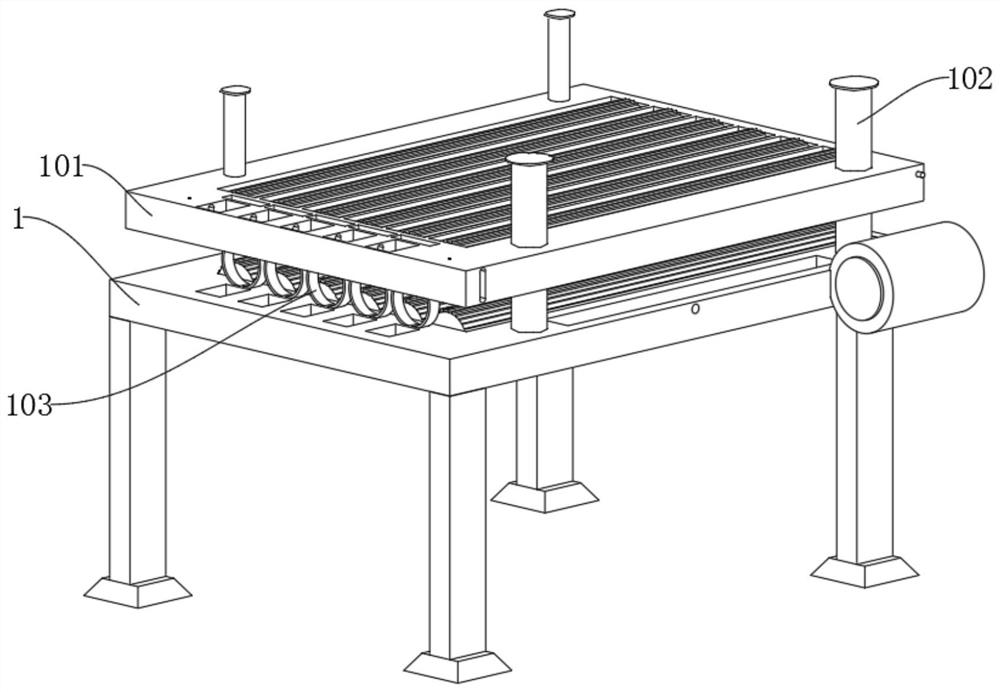

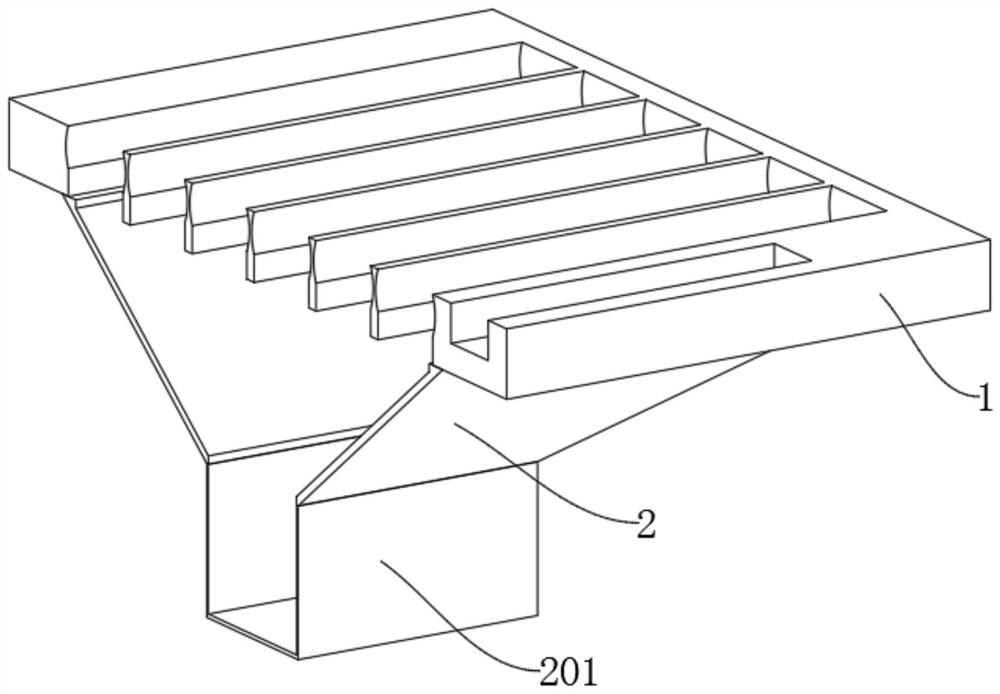

[0034] as attached figure 1 to the attached Figure 8 Shown:

[0035] The invention provides a steel pipe surface derusting device for construction engineering, comprising a main body 1, a bottom plate 2, a transverse groove 3, a chute 4, a top groove 5, a push plate 6 and a carrier plate 7, a motor is installed on the side of the main body 1, and The bottom of the main body 1 is equipped with legs; the bottom plate 2 is a tapered structure, and the bottom plate 2 is set on the top of the main body 1; Bottom; the top groove 5 is located on the side of the top plate 101, and the insertion rod 503 at the top of the top groove 5 is installed on the top of the top plate 101;

[0036] Transverse groove 3 comprises running wheel 301, connecting rod 302, rotating rod 303, and the side of running wheel 301 is provided with rubber pad, and running wheel 301 is installed in the inside of horizontal groove 3; Connecting rod 302 is installed in the inside of horizontal groove 3, And conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com