Numerical control stone cutting machine, cutting tool bit and control method of cutting tool bit

A cutting head, stone cutting machine technology, applied in electrical program control, program control in sequence/logic controllers, manufacturing tools, etc., can solve waste, does not have the structure and function of moving stone unit panels at will, and is easy to bruise Stone unit board and other problems, to achieve the effect of reducing waste, simple structure and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through specific embodiments.

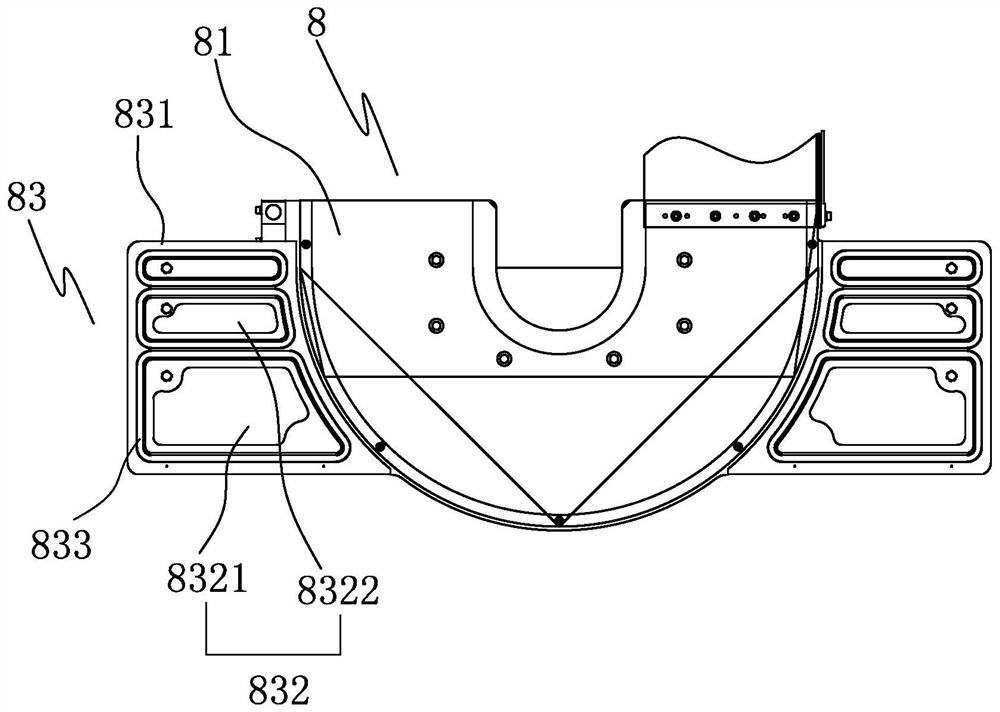

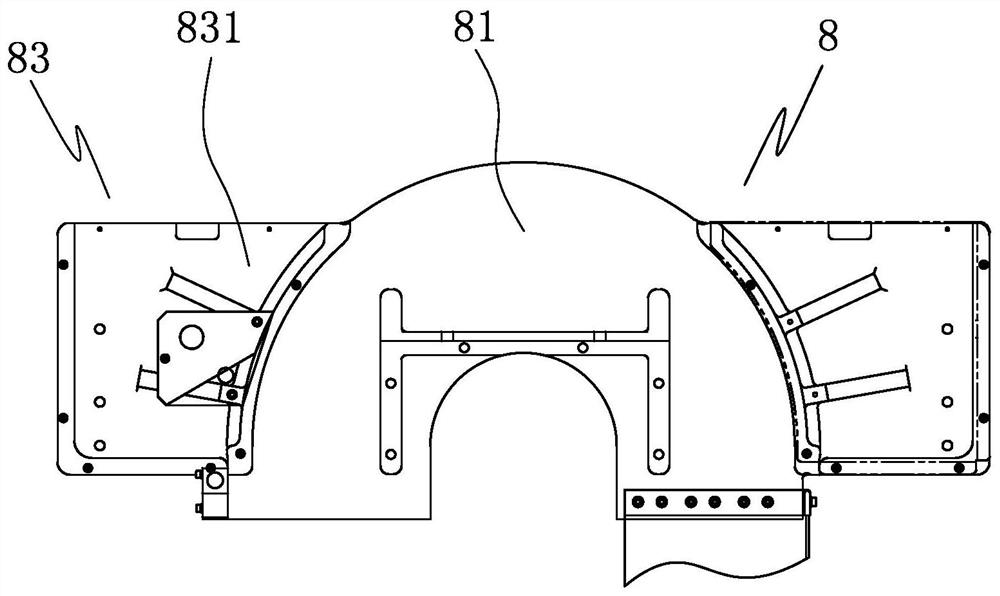

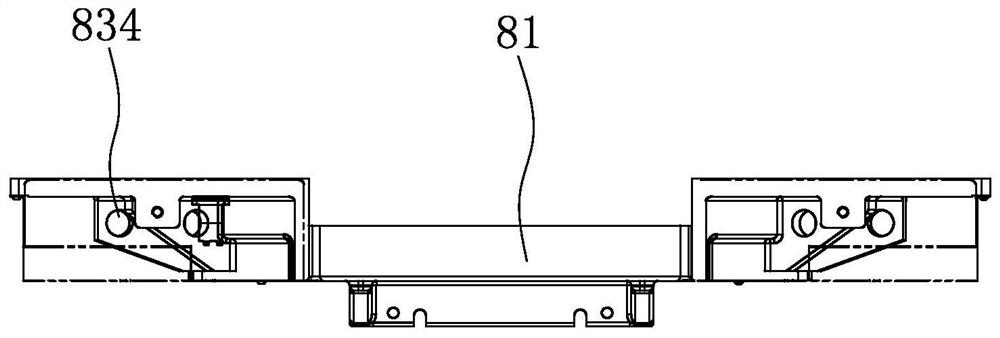

[0039] refer to Figure 1 to Figure 15 As shown, a five-axis CNC stone cutter includes a frame 1, a workbench 2, a cutter head mounting frame 3, a cutting cutter head 8 and a driving device.

[0040] The frame 1 includes two bases 11 oppositely arranged and a beam 12 arranged between the two bases 11 which can move back and forth.

[0041] The workbench 2 is arranged between the two bases 11 for placing stone materials.

[0042] The cutter head installation frame 3 is arranged on the crossbeam 12, is used for installing the cutting cutter head 8, comprises the bottom frame 31 that can move left and right to be arranged on the crossbeam 12, can move up and down and be arranged on the lifting frame 32 that is arranged on the bottom frame 31 and be arranged on the lifting frame 31. A rotating frame 33 that can rotate around a vertical axis on the frame 32.

[0043] The drive device is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com