Wheel disc assembly, air door control mechanism and automobile air outlet

A technology for air outlets and roulettes, which is applied in the field of air door control mechanisms and automotive air outlets and roulette components. It can solve the problems of high scrap rate, high labor cost, and unsmooth combination, achieving high pass rate, reducing production costs and The effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

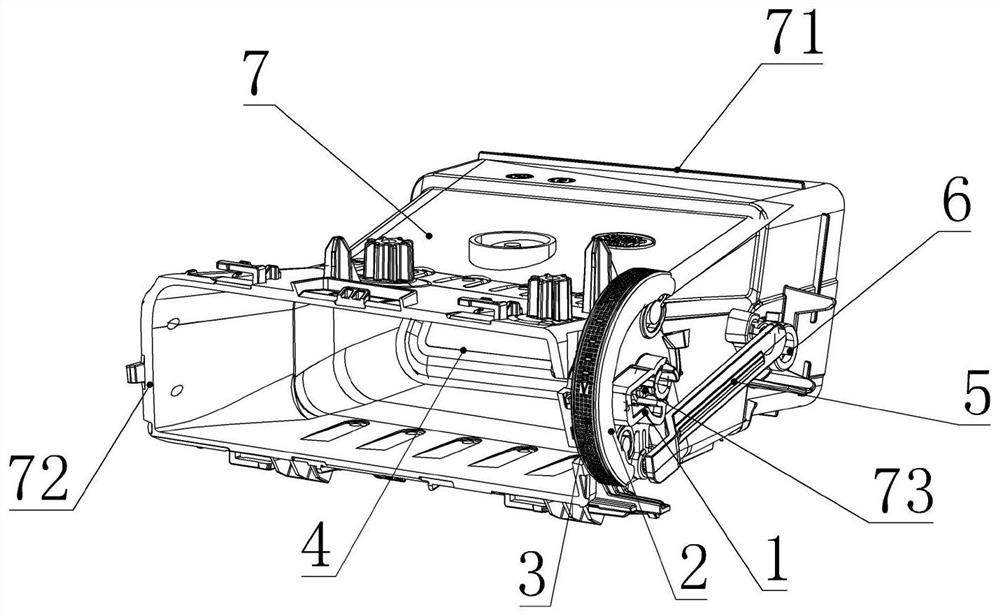

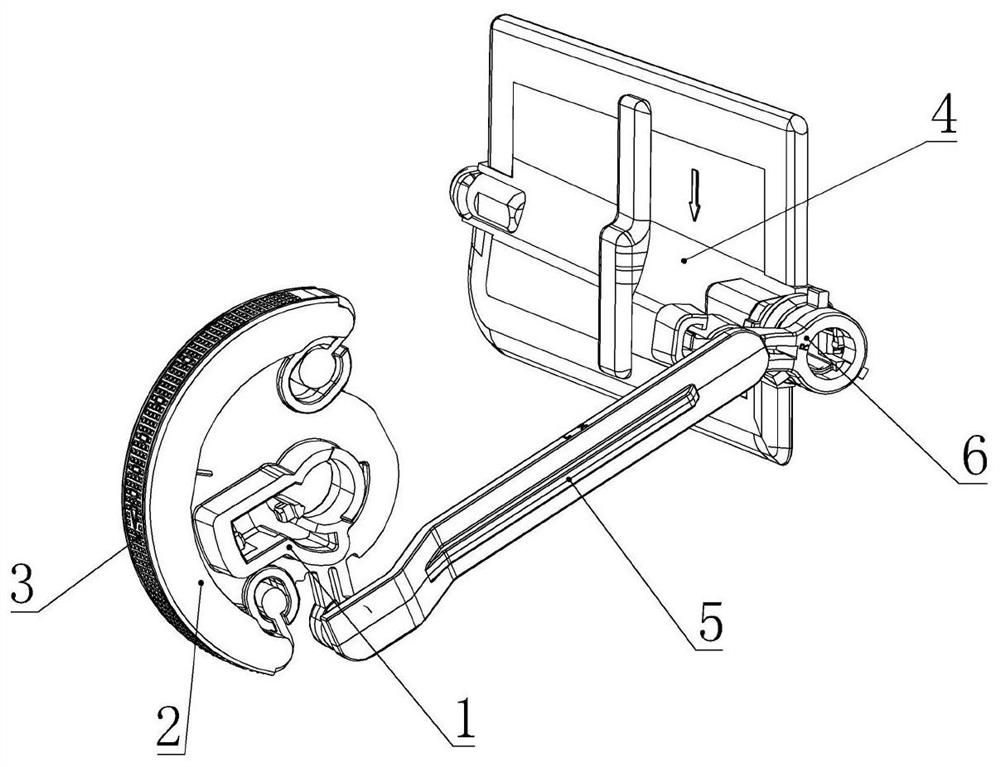

[0051] Such as Figure 1-6 A wheel assembly, a damper control mechanism and an automobile air outlet shown include: a housing 7 and a damper control mechanism, the damper control mechanism is installed on the housing 7; the damper control mechanism includes a wheel assembly , the transmission mechanism and the damper 4; the roulette assembly and the damper 4 are respectively located at the two ends of the transmission mechanism and connected with the transmission mechanism; the roulette assembly is connected with the damper 4 through a rotating mechanism, and the roulette firmware is rotated, The damper 4 can be driven to rotate by the rotating mechanism, the opening and closing of the damper 4 can be controlled, and the air output volume in the casing 7 can be changed.

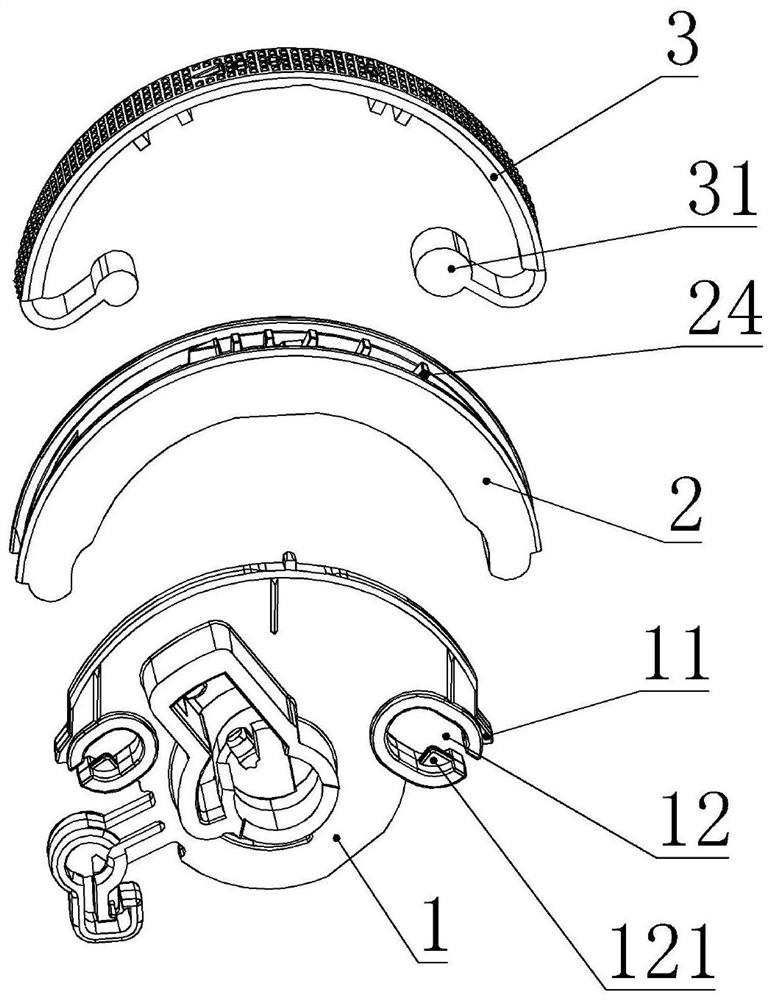

[0052] The roulette assembly includes: a roulette frame 1, with clip feet 11 provided on both sides of the roulette frame 1, and connecting grooves 12 provided below the clip feet 11; Both ends are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com