Layout method of monorail crane track beam based on equipment layout

A technology for rail beams and monorail cranes, applied in the direction of rail system, load hanging components, transportation and packaging, etc., can solve the problems of application limitations, lateral movement of monorail crane rails, etc., to reduce production and transportation costs, improve product production efficiency, The effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

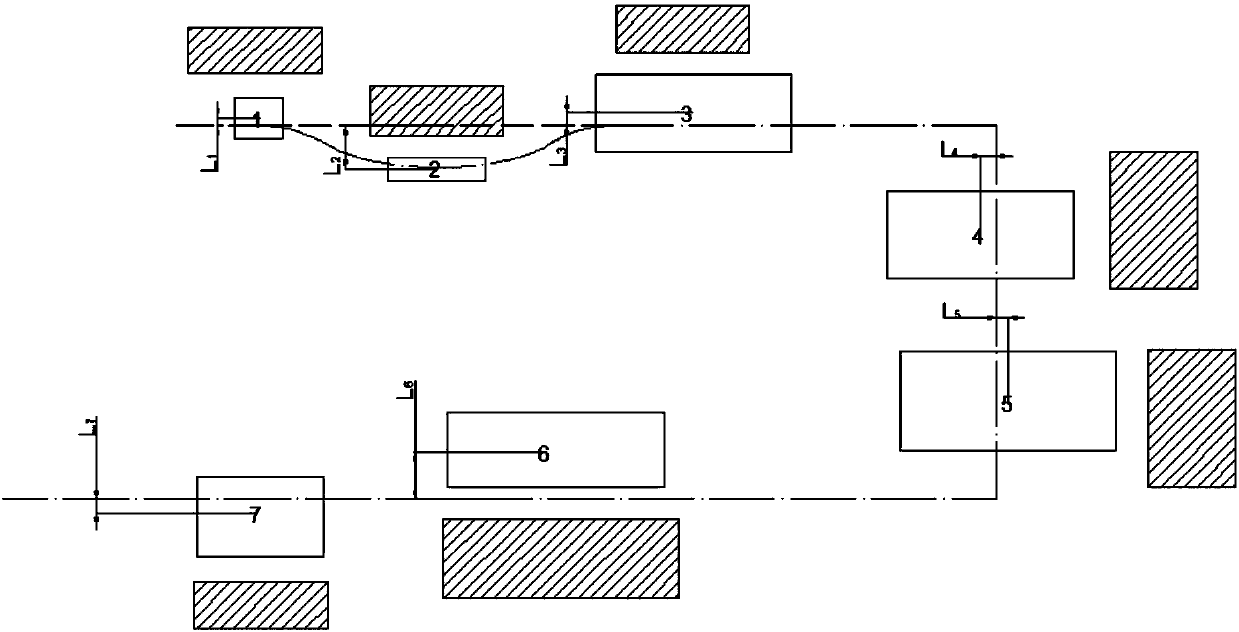

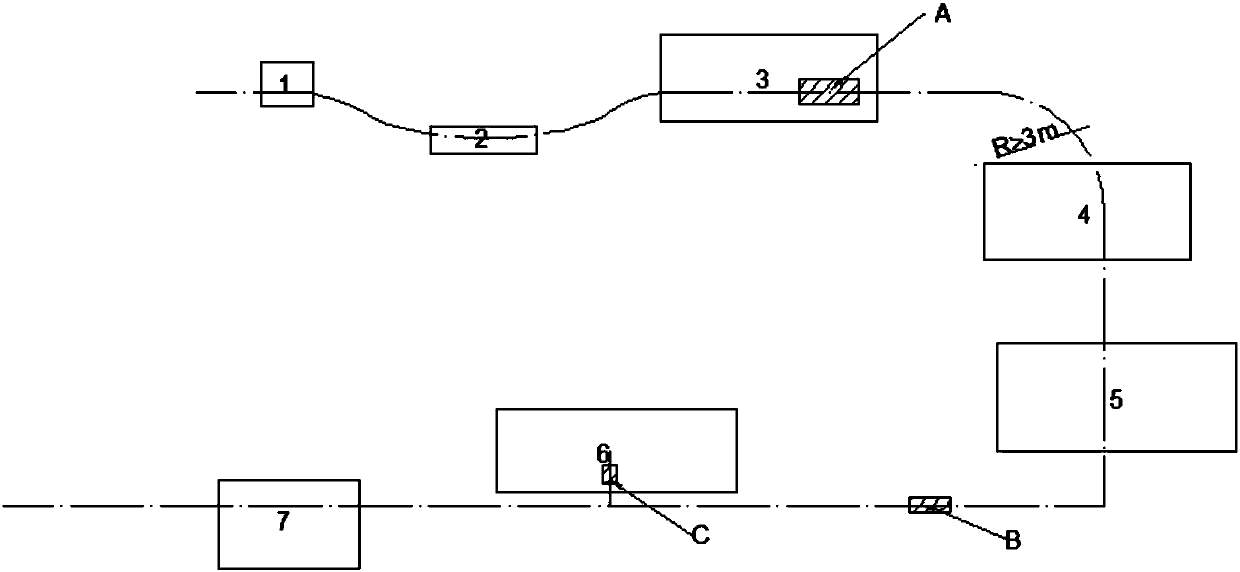

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] As a commonly used auxiliary transportation equipment, monorail crane has the advantages of simple structure, convenient structure and low price, so it has been widely used in engineering, especially in the field of assembly line mass production technology widely used in factories at present. When the volume or quality of the equipment is relatively large, the required conveyor belt will not be suitable for the assembly line transportation of the equipment. At the same time, since the monorail crane can well complete the equipment transportation in a straight line and can bear a large working load, but it cannot move laterally like the crane, so this method aims to propose a method based on the characteristics of the site equipment layout. The method of monorail crane track beam layout to solve the problem of auxiliary transportation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com