A kind of preparation method of multi-component low-density glass microbead prepreg

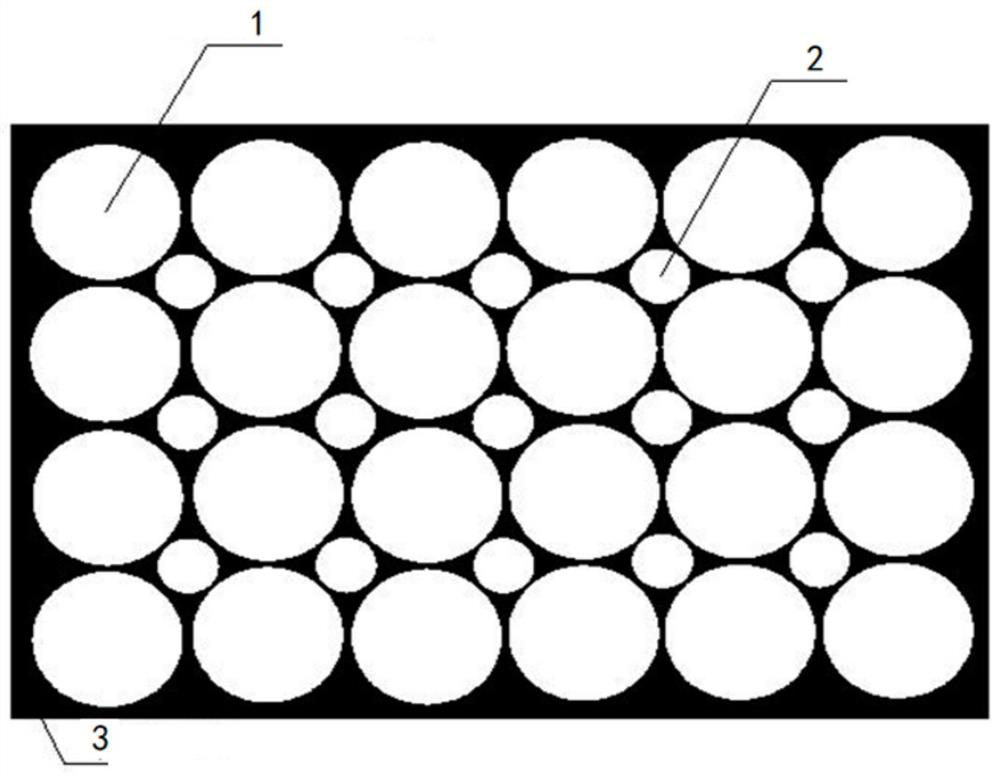

A technology of glass microspheres and low density, applied in chemical instruments and methods, glass/slag layered products, layered products, etc. Mechanical properties and other issues, to achieve the best mechanical strength and heat insulation effect, good applicability, and the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The equipment used in this embodiment includes a glue dipping machine, a glue coating machine, and a compound machine; the structure of the glue dipping machine is mainly composed of a glue tank, a cloth threading roller, a pre-curing furnace, a winding mechanism, etc. The structure of the glue coating machine mainly includes: It is composed of glue tank, extruding roller, pre-curing furnace, winding mechanism, etc. The structure of the compound machine is mainly composed of double-layer cloth threading roller, film peeling roller, pressing machine, hot roller and rewinding mechanism. Example 1. Manufacture of multi-component low-density glass bead prepreg

[0083] The specific operations are:

[0084] Step 1. Selection of materials and proportions: the preparation length is 20m, and the density requirement of the multi-component low-density glass bead prepreg is ≤0.75kg / m 3 ; The requirement for tensile strength is ≥25Mpa; the ratio of the amount of barium phenolic re...

Embodiment 2

[0091] Example 2. Manufacturing of multi-component low-density glass microbead prepreg

[0092] The specific operations are:

[0093] Step 1. Selection of materials and proportions: the preparation length is 50m, and the density requirement of the multi-component low-density glass bead prepreg is ≤0.75kg / m 3 ; The requirement for tensile strength is ≥25Mpa; the ratio of the amount of barium phenolic resin, glass fiber mesh, and glass microbeads used is calculated to be 5:4:2; 9:1; the model of large-diameter glass beads is S20; the model of small-diameter glass beads is S32;

[0094] Step 2. Heat treatment of glass fiber mesh cloth: put 12kg of glass fiber mesh cloth into the pre-curing furnace of the dipping machine, heat treatment at a temperature of 330 ° C, and then cool down to 90 ° C;

[0095] Step 3. Impregnating the fiber cloth: Take 3kg of barium phenolic resin and pour it into the glue tank of the glue dipping machine in Step 2. Under the condition of 90°C and a ru...

Embodiment 3

[0099] Example 3. Manufacturing of multi-component low-density glass microbead prepreg

[0100] The specific operations are:

[0101] Step 1. Selection of materials and proportions: the preparation length is 20m, and the density requirement of multi-component low-density glass bead prepreg is ≤0.75kg / m 3 ; The tensile strength requirement is ≥ 25Mpa; the ratio of the amount of barium phenolic resin, glass fiber mesh cloth, and glass microbeads used is calculated to be 4:3:2; 8:1; the model of large-diameter glass beads is S15; the model of small-diameter glass beads is S25;

[0102] Step 2. Heat treatment of glass fiber mesh cloth: put 3kg of glass fiber mesh cloth into the pre-curing furnace of the dipping machine, heat treatment at a temperature of 350 ° C, and then cool down to 110 ° C;

[0103] Step 3. Impregnating the fiber cloth: Take 0.33kg of barium phenolic resin and pour it into the glue tank of the dipping machine in step 2. Under the condition of 110°C and the ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com