Gear box jointly driven by winch and turntable

A technology of gear boxes and turntables, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of complex structure of the drill shaft, large volume of the gearbox, and large space occupation, and achieve good drilling characteristics, high transmission efficiency, Overall weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

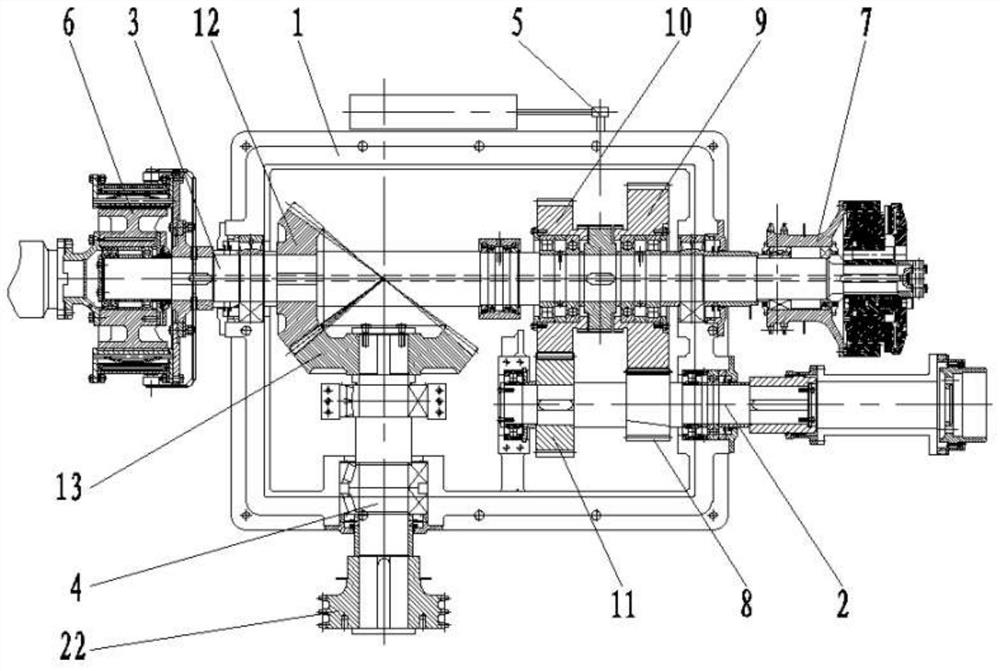

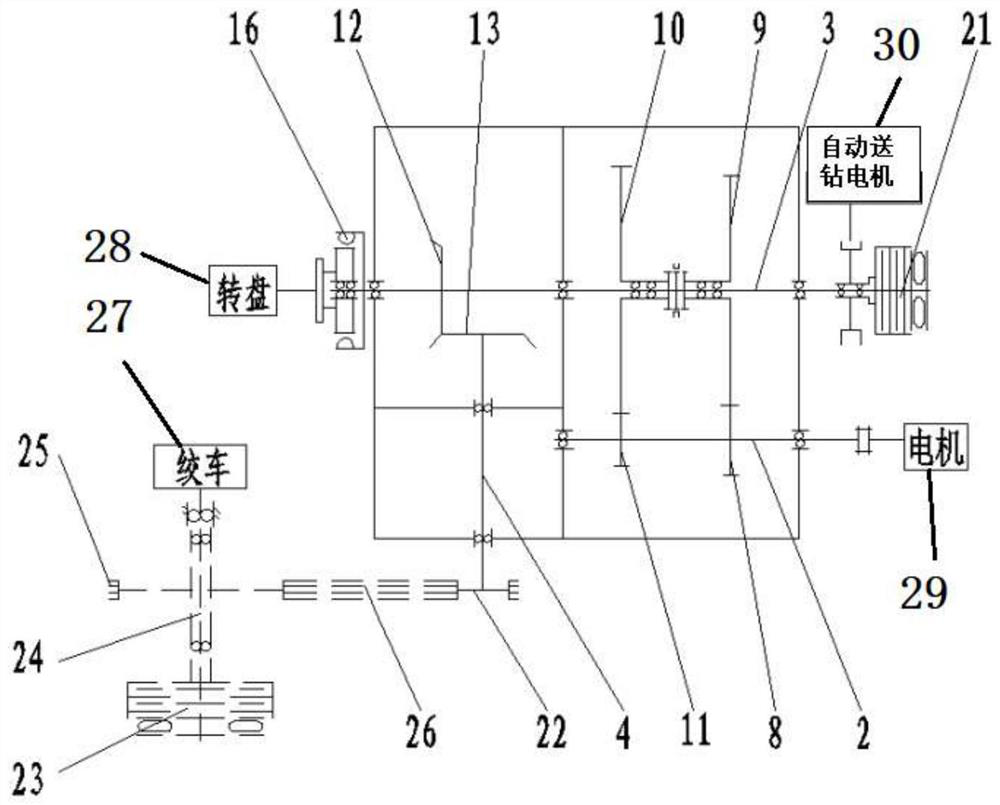

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] refer to figure 1 , figure 2 , image 3 with Figure 4 , the structure of the device of the present invention is to include a box body 1, the box body 1 is equipped with an input shaft assembly 2, an intermediate shaft assembly 3 and an output shaft assembly 4 through a bearing seat, and the three shaft assemblies are connected by gears Engagement transmits power and torque;

[0022] The input shaft assembly 2 is connected with the motor 29 to provide power for the entire gearbox. The input shaft assembly 2 is coaxially fixed with a spur gear I8 and a spur gear IV11, and both the spur gear I8 and the spur gear IV11 are located in the box body 1. in the cavity;

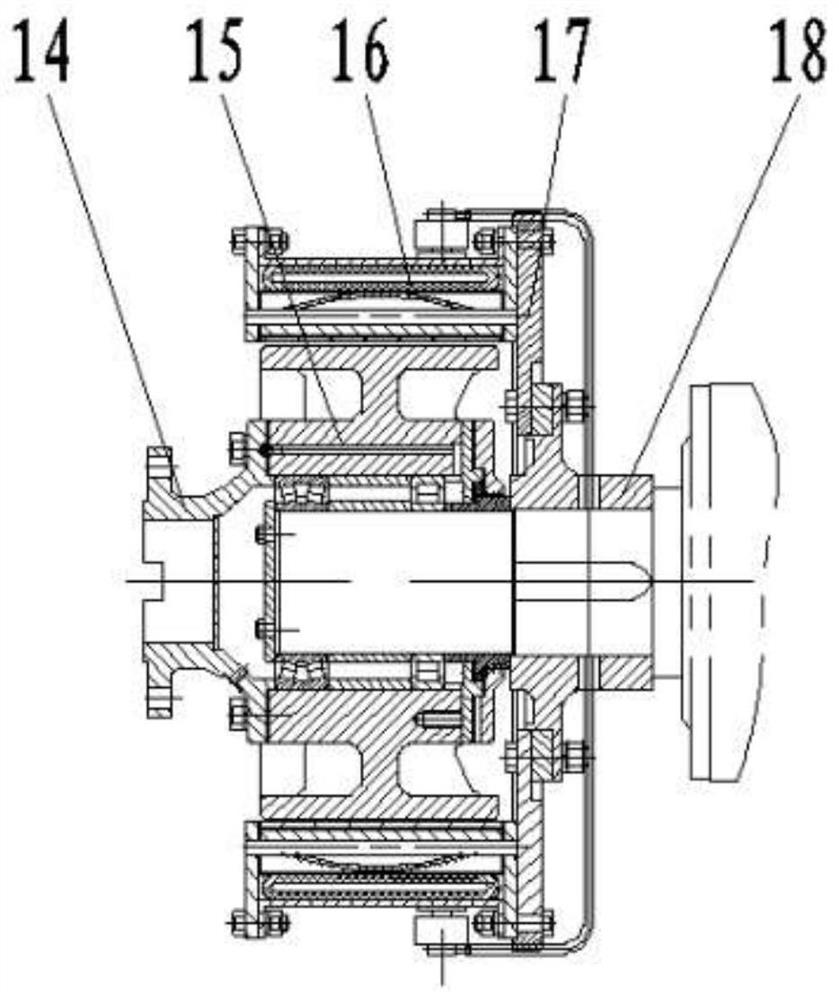

[0023] One end of the intermediate shaft assembly 3 protruding from the box body 1 is connected with an automatic drill feed clutch assembly 7. The automatic drill feed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com