Construction method for high viscosity modified asphalt pavement

A technology of modified asphalt and construction method, which can be applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of energy waste, poor storage stability, and storage tank occupation, and achieve improved driving safety factor and reduced noise , Reduce the effect of rainwater inundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of high-viscosity modified asphalt pavement construction method, and in a kind of preferred embodiment, it comprises the steps:

[0032] S1. Prepare construction equipment;

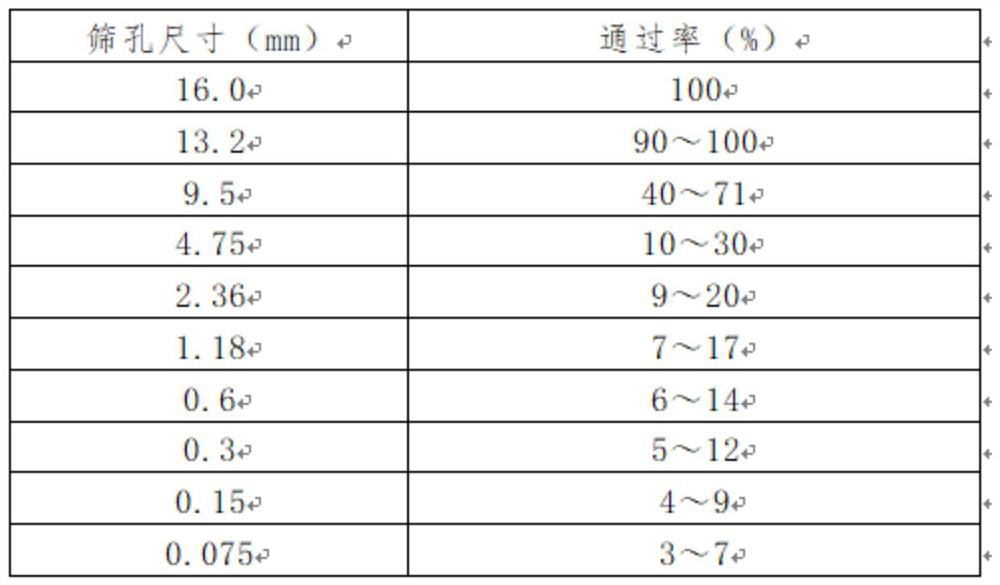

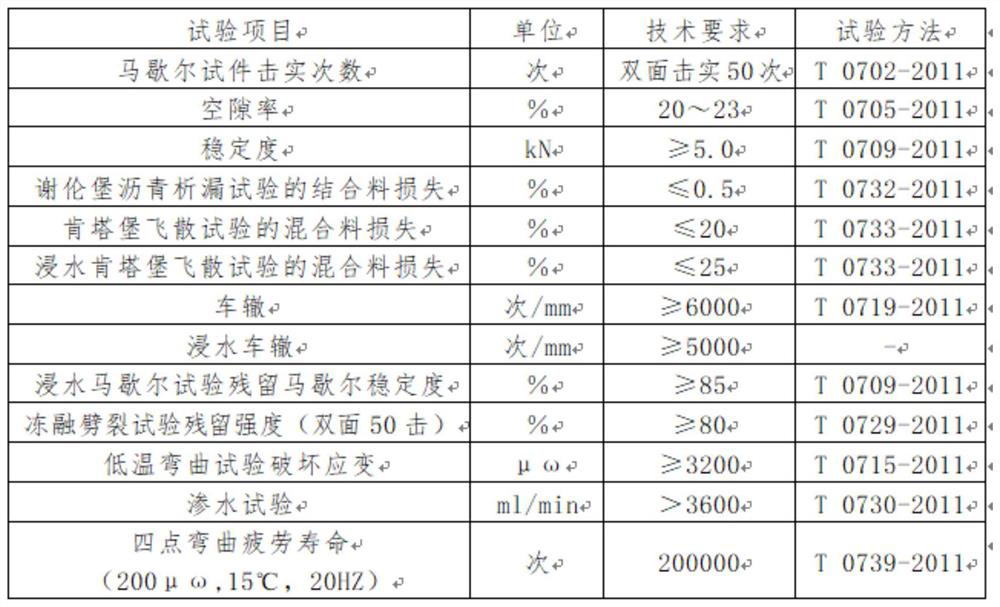

[0033] S2. Design the mix ratio of high-viscosity modified asphalt and high-viscosity modified asphalt mixture, and treat the road surface with a waterproof bonding layer;

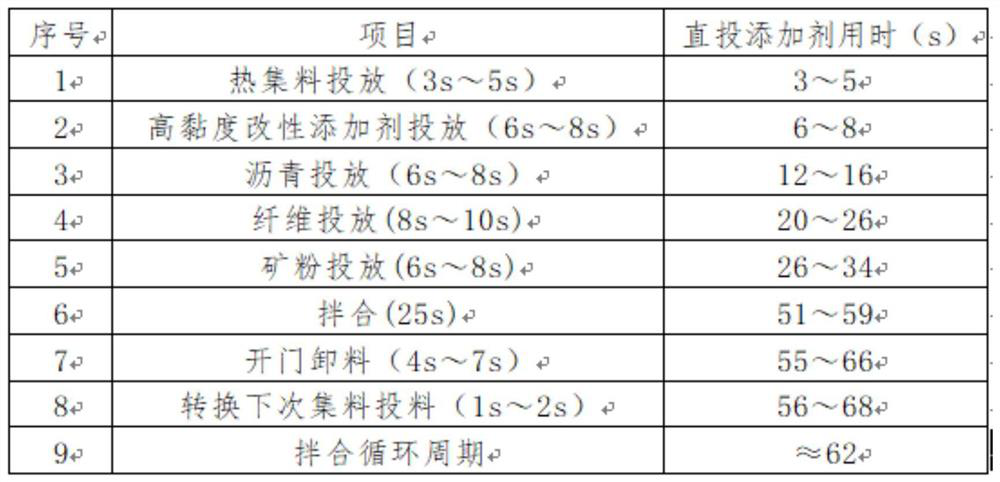

[0034] S3. Mixing of high-viscosity modified asphalt mixture, the high-viscosity modified asphalt is directly put into the asphalt mixture mixer with a feeding device for mixing;

[0035] S4, transporting the high-viscosity modified asphalt mixture to the construction site;

[0036] S5. Preparatory work before paving the high-viscosity modified asphalt mixture;

[0037] S6, select and adjust the use parameters of the paver;

[0038] S7, carry out paving operation;

[0039] S8, rolling the high-viscosity modified asphalt mixture into shape;

[0040] S9, seam treatment.

[0041] The hi...

Embodiment 2

[0068] This embodiment provides a delivery device, which can be used to deliver the high-viscosity modified asphalt in Example 1 into the asphalt mixer. Such as Figure 4 As shown, in a preferred embodiment, the delivery device includes a tank body 10, the tank body 10 is provided with a storage tank 20, an electronic weighing module 40 for weighing the storage tank 20, located in the storage tank 20 below and the feed tank 30 communicating with the feed tank 20 , and the blowing module 50 connected with the feed tank 30 . In this embodiment, the electronic weighing module 40 can be an electronic scale or a weight sensor with a digital display screen in the prior art, and the blowing module 50 can be a blower or a high-pressure air jet in the prior art.

[0069] Wherein, the storage tank 20 is vertically arranged, there is a gap between the outer wall of the storage tank 20 and the inner wall of the tank body 10, the top of the tank body 10 is provided with a feeding port 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com