A kind of maintenance equipment used for front-loading machines in open-pit coal mines

A technology for maintaining equipment and open-pit coal mines. It is applied in the field of maintenance equipment for front-mounted equipment in open-pit coal mines. It can solve problems such as reducing maintenance efficiency, affecting operating efficiency, and being unable to adjust maintenance equipment.

Active Publication Date: 2022-05-31

BEIFANG WEIJIAMAO COAL POWER CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to ensure the normal operation of the front-loading machine, it is necessary to maintain the front-loading machine on a regular basis. However, although the maintenance equipment for the front-loading machine in open-pit coal mines on the market can perform basic maintenance on the front-loading machine, there are still the following defects: 1. Effectively clean the chassis of the front-mounted machine. There is a lot of dust in the working environment of the front-mounted machine. A large amount of dirt adheres to the chassis of the front-mounted machine. If it is not cleaned for a long time, the chassis of the front-mounted machine will be rusted and its service life will be greatly shortened; 2. The height of the maintenance equipment cannot be adjusted according to the maintenance personnel with different heights. It is not convenient for the maintenance personnel to overhaul the chassis of the front-installed machine, fasten the bolts of the chassis and replace the parts of the chassis. Labor intensity reduces maintenance efficiency; 3. The oil pan used to hold the pre-installed engine oil is generally shaped, so when removing the oil drain screw of the oil pan, all the old oil cannot be released, and some The old engine oil remains in the oil pan, and the residual old engine oil and new engine oil are mixed together, which will affect the performance of the new engine oil; 4. The level of the bucket cannot be corrected. If the bucket is tilted, it will seriously affect the operating efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

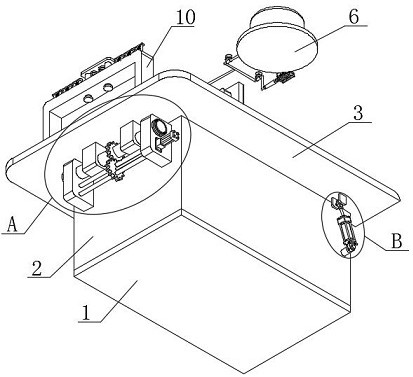

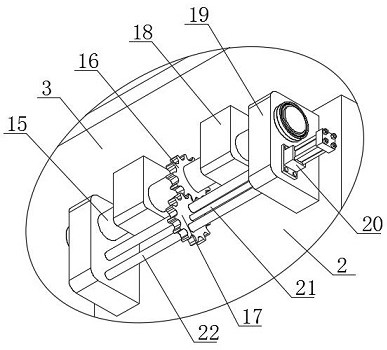

[0057] The top of the top plate 3 is fixedly mounted with a translation assembly, and the translation assembly is provided with a sliding plate 74. The top of the sliding plate 74

[0058] The top side of the top plate 3 is fixedly installed with a U-shaped frame 10, and the top of the U-shaped frame 10 is symmetrically provided with two second through holes,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

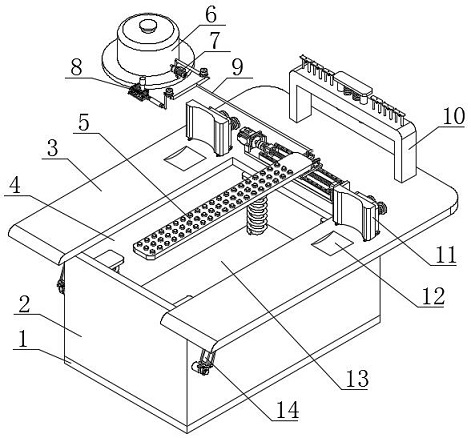

Login to View More Abstract

The invention discloses a maintenance device for front-mounted machines in open-pit coal mines, which comprises a bottom plate fixedly installed in the ground, a rectangular box is fixedly installed on the top of the bottom plate, and a drain pipe is fixedly connected to one side of the rectangular box. One side of the rectangular box is rotatably connected with a top plate, the bottom of the top plate is in contact with the top of the rectangular box and the top of the ground, the four corners of the top of the bottom plate are welded with supporting columns, and the inner walls of both sides of the rectangular box are Two transverse plates are symmetrically welded, and the tops of the four support columns are respectively welded to the bottoms of the four transverse plates. The beneficial effects of the present invention are: the present invention has a compact structure, can effectively clean the chassis of the front-mounted machine, prolongs the service life, and can adjust the height of the moving plate according to the height of the maintenance personnel, which is convenient for the maintenance personnel to perform maintenance operations, making it possible to Improve maintenance efficiency, clean the chassis, adjust the level of the bucket, change the engine oil more thoroughly, and reduce the labor intensity of workers.

Description

A maintenance equipment for front loading of open-pit coal mines technical field [0001] The present invention relates to the technical field of open-pit coal mines, in particular to a maintenance equipment used for front-loading of open-pit coal mines. Background technique [0002] An open-pit coal mine refers to a coal layer deposited on the surface or shallow layers due to geographic changes, and the For mines, when the ore layer is close to the surface, it is more economical to use open-pit mining, and the soil above the ore layer is called topsoil. not yet open Explosives are embedded in the topsoil strips released, then the topsoil is removed using dredgers, excavators, trucks, etc., which is then filled After the topsoil is removed, the ore layer will be exposed. At this time, the ore blocks are drilled or blasted into pieces. Before use The installation loads the ore into trucks and transports it to the coal preparation plant for further processing. In order ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21C47/02

CPCE21C47/02Y02P70/10

Inventor 刘宏宇王士维丁建华周春芳郑开慧冀宪成韩凤飞王国杰石晓东张永贵韩宇段晓磊姜波

Owner BEIFANG WEIJIAMAO COAL POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com