Hydraulic plunger pump swash plate inclination angle stepless adjusting mechanism and adjusting method thereof

A hydraulic plunger pump, stepless adjustment technology, applied in the direction of liquid variable displacement machinery, pumps, multi-cylinder pumps, etc., can solve the problem of pollutants easily brought in by adjustment and replacement, inconvenient replacement and adjustment process, and pollutants entering the pump chamber and other problems to achieve the effect of avoiding length grading, convenient adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

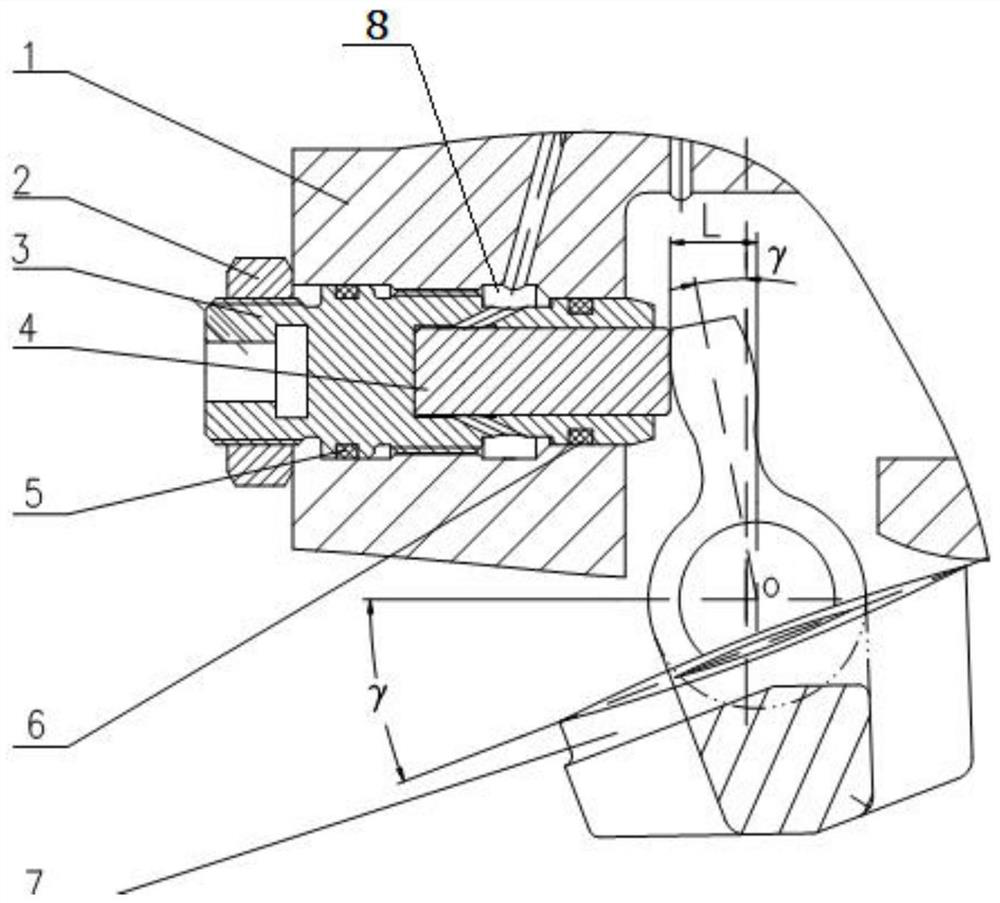

[0015] Example. A hydraulic plunger pump swash plate inclination stepless adjustment mechanism, constituted as follows figure 1 and figure 2 As shown, it includes the plunger pump housing 1, and one end of the plunger pump housing 1 is provided with a swash plate 7, and the plunger pump housing 1 is also provided with an adjusting screw hole 8 corresponding to the position of the swash plate 7, and the adjusting screw hole 8 is provided with a stepless adjustment follower piston sleeve 3, and the inner side of the stepless adjustment follower piston sleeve 3 is provided with a fixed follower piston 4 matching with the swash plate 7; the stepless adjustment follower piston sleeve The outer side of 3 is provided with lock nut 2.

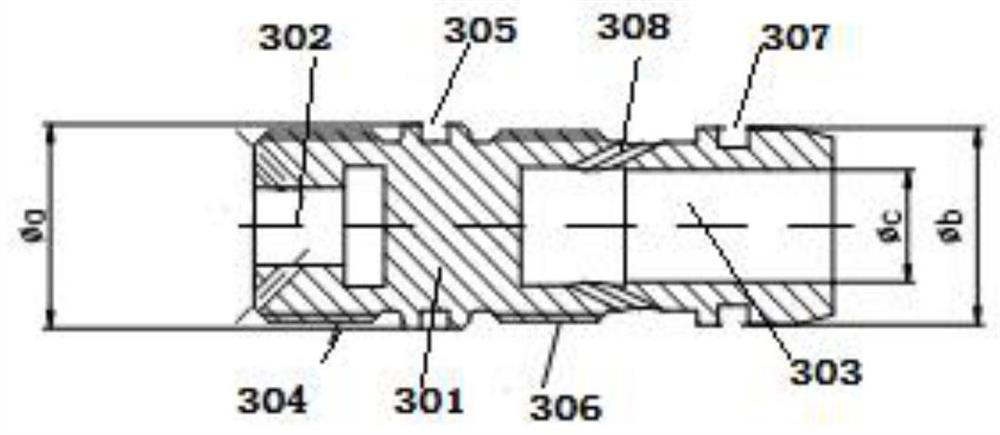

[0016] The stepless adjustment follower piston sleeve 3 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com