Air compressor cylinder body multi-hole machining device with auxiliary positioning mechanism

An auxiliary positioning and air compressor technology, applied in mechanical measuring devices, using mechanical devices, measuring devices, etc., can solve the problems of many uncontrollable factors, increased labor burden, and large error range, so as to improve air quality and reduce work. The effect of burden and error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

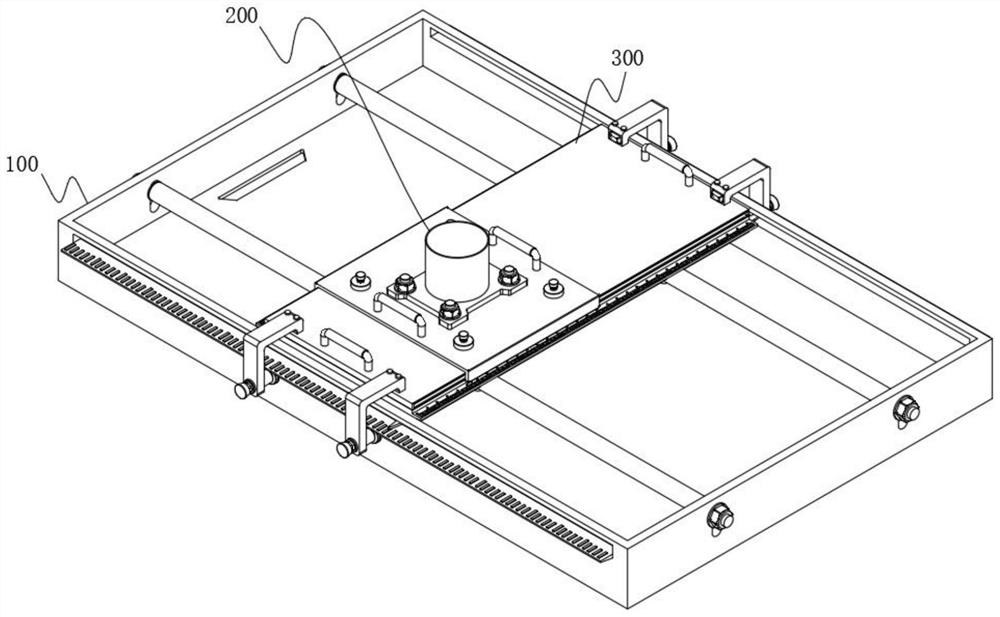

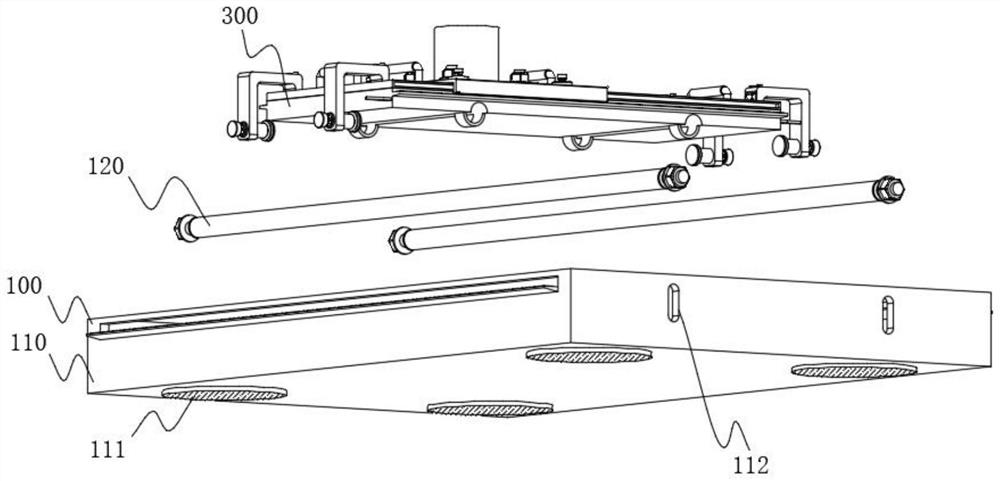

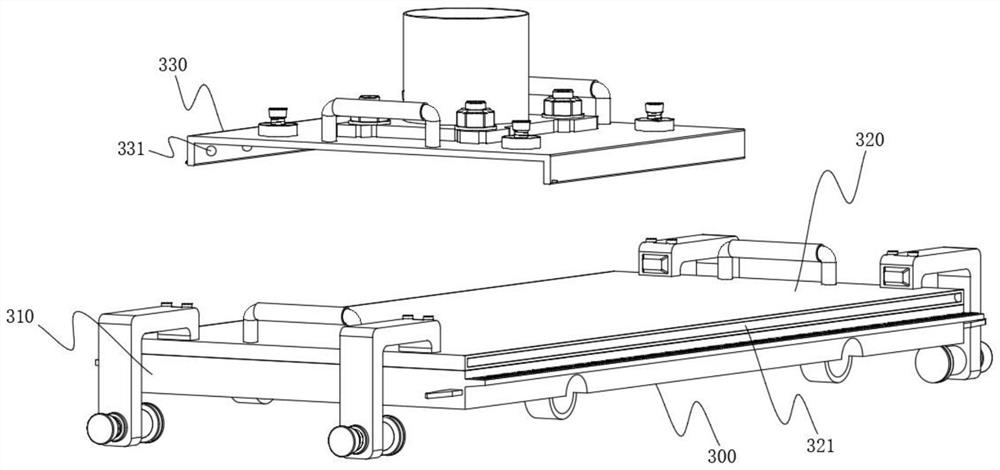

[0060] The invention provides an air compressor cylinder porous processing device with an auxiliary positioning mechanism, please refer to Figure 1-Figure 15 , including a support mechanism 100 and a cylinder body 200 arranged on the top of the support mechanism 100, the cylinder body 200 includes a mounting plate 210 fixed on its bottom, and mounting holes 211 are opened at the four corners of the mounting plate 210, and the mounting holes 211 are used for Cooperate with the bolts to install and fix the cylinder body 200. The support mechanism 100 includes a support seat 110. Two connection holes 112 are provided on the front and rear side walls of the support seat 110. A slide bar 120 is arranged between the front and rear connection holes 112. The two ends of the rod 120 are provided with connecting rods 121, and the connecting rods 121 are plugged and matched with the connecting holes 112. The left and right side walls of the support mechanism 100 are provided with bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com