Binary mixed solvent system and application of binary mixed solvent system to preparation of perovskite material

A perovskite material and binary mixing technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as high boiling point, unstable solution state, and restrictive preparation, so as to simplify the process flow, Reduce the effect of uncontrollable factors and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Correspondingly, another aspect of the embodiments of the present invention also provides a method for preparing a perovskite film, which includes:

[0051] A perovskite precursor solution is provided, the perovskite precursor solution includes a perovskite precursor and a solvent, and the solvent includes an amine compound and ethanol with a volume ratio of 0.1-1:0.1-2;

[0052] Perform film-forming treatment on the perovskite precursor solution at room temperature to prepare a perovskite film.

[0053] In some embodiments, the preparation method specifically includes: forming a film on the perovskite precursor solution by one-step spin coating method at room temperature, wherein the spin coating speed used is 1000-5000 rpm, The acceleration is 500-10000 rpm / s, and the spin-coating time is 5-30s.

[0054] Further, the method for preparing the perovskite film by the low-boiling point binary mixed solvent system is various, and various techniques such as scraping coatin...

Embodiment 1

[0059] Embodiment 1 prepares perovskite precursor solution

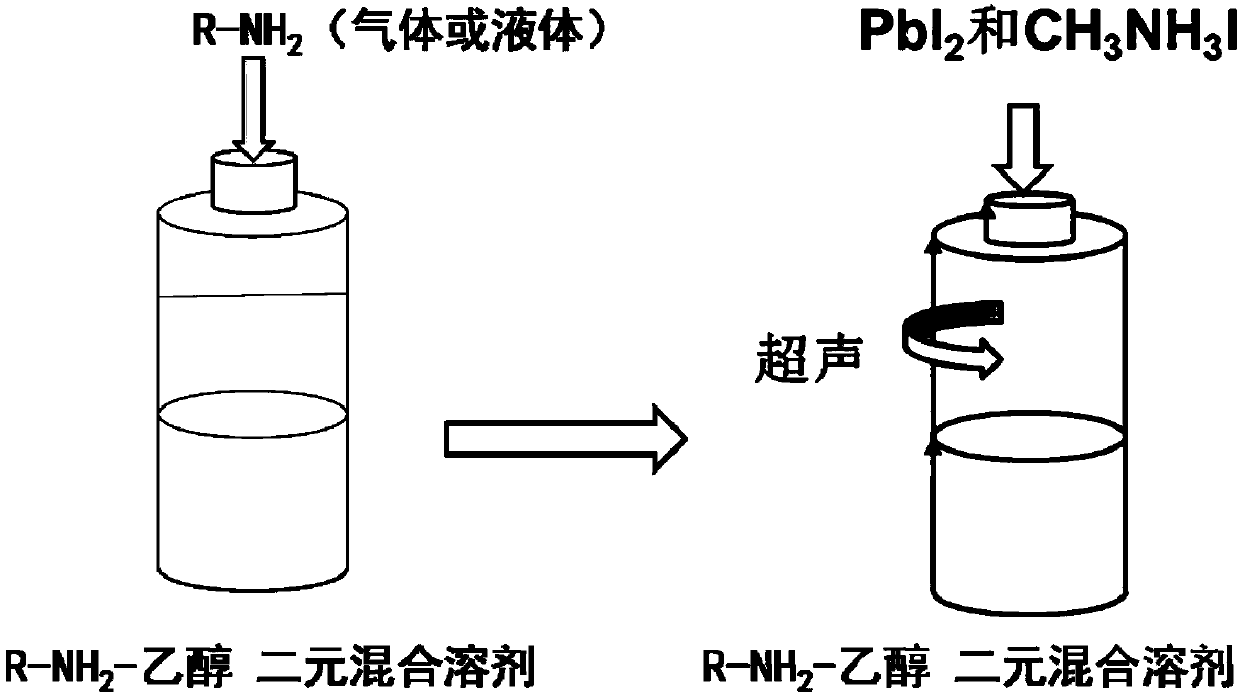

[0060] see figure 1 As shown, the process of preparing the perovskite precursor solution using a low boiling point binary mixed system solvent: the concentration of the precursor solution is 0.5mol / L, and the molar ratio is 1.2:1 lead iodide (PbI 2 ) and methyl iodide (CH 3 NH 3 1) Dissolved in a mixed solvent of methylamine-ethanol-acetonitrile with a volume ratio of 0.5:1, through continuous ultrasonication and stirring, the two are fully dissolved in the binary low-boiling point system, and finally a clear and transparent perovskite can be obtained ore precursor solution.

Embodiment 2

[0061] Embodiment 2 prepares perovskite precursor solution

[0062] The process of preparing the perovskite precursor solution using a low-boiling point-high boiling point mixed system solvent: the concentration of the precursor solution is 1mol / L, and the molar ratio is 1:0.1 lead iodide (PbI 2 ) and methyl iodide (CH 3 NH 3 I) Dissolved in a mixed solvent of methylamine-ethanol with a volume ratio of 0.1:0.1, through continuous ultrasonic and stirring, the two are fully dissolved in the binary low-boiling point system, and finally a clear and transparent perovskite can be obtained precursor solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com