Manufacturing industry information quantitative analysis method and device based on analytic hierarchy process

An analytical hierarchy process and quantitative analysis technology, applied in the field of computer analysis, can solve the problems of inaccuracy, inconsistent calculation scale, low utilization rate of evaluation data visualization, etc., to achieve scientific evaluation results, improve accuracy and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

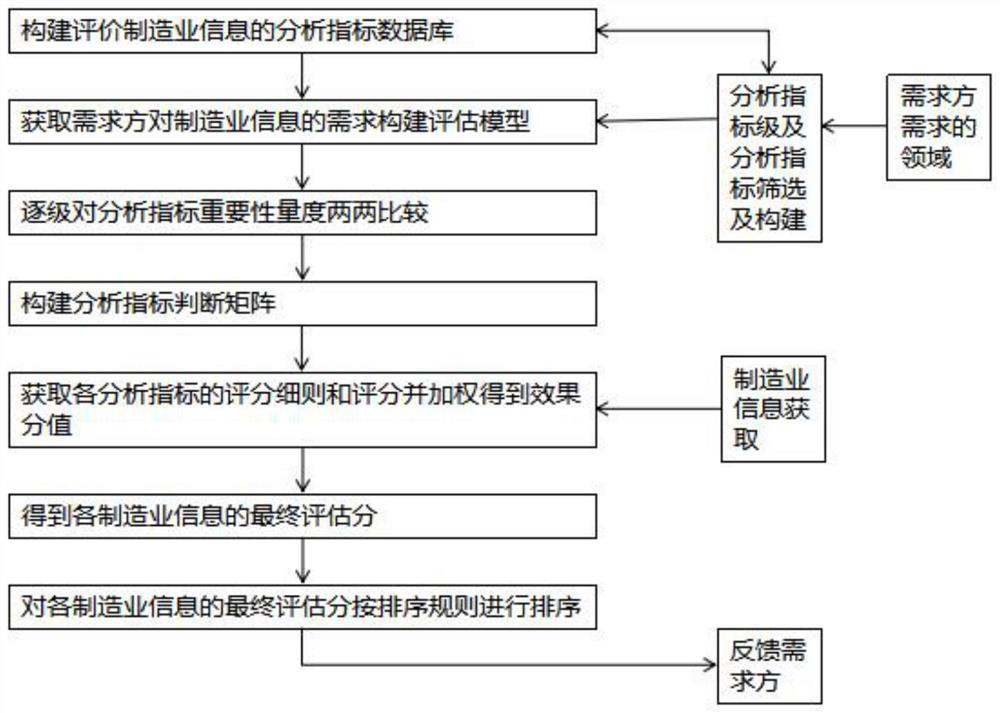

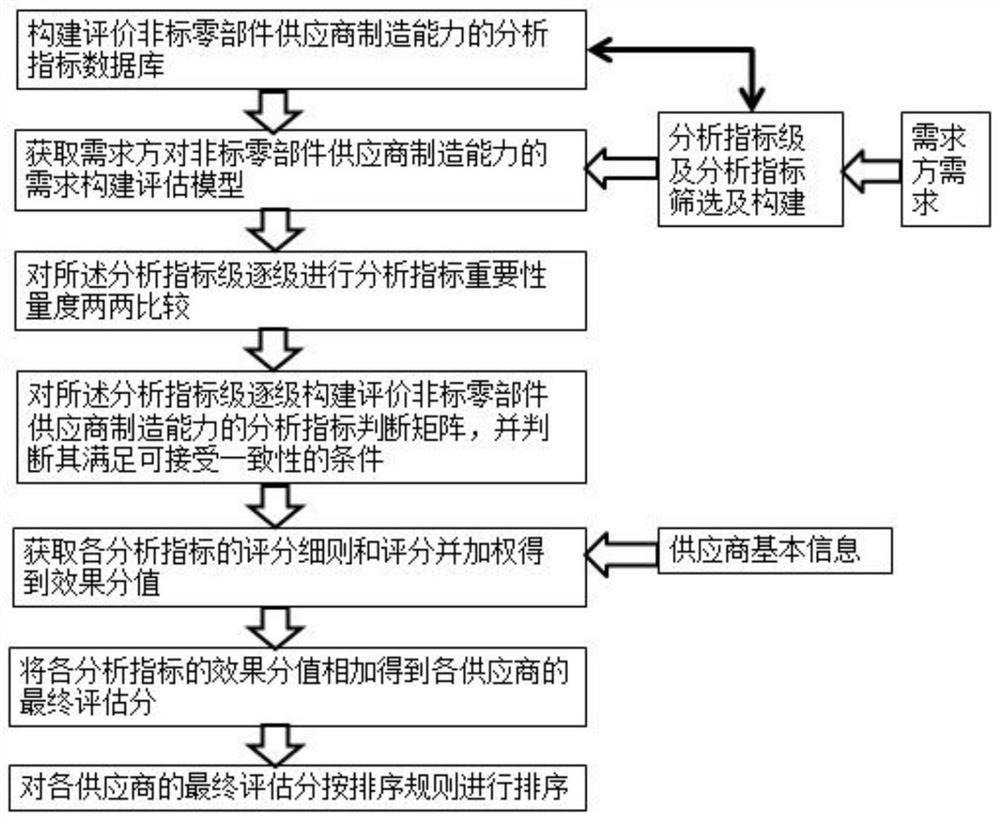

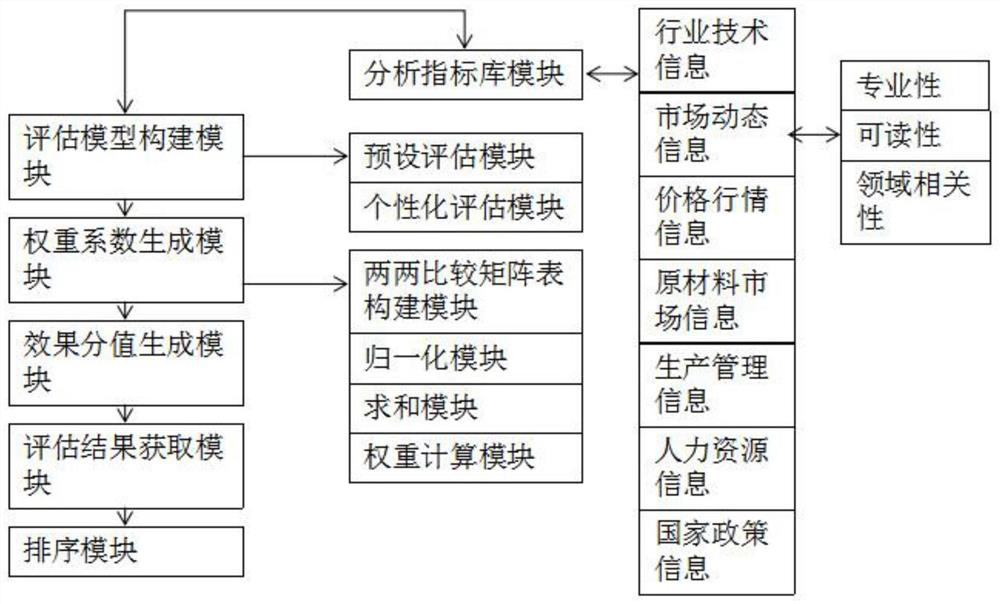

[0043] For further elaborating the technical means and effect that the present invention takes to reach the predetermined invention purpose, combine figure 1 , 2 The details are as follows.

[0044] A method for quantitative analysis of manufacturing information based on analytic hierarchy process, the method comprising:

[0045] Constructing an analysis index database for evaluating manufacturing information, the analysis indexes in the analysis index database are divided into several analysis index levels, and each analysis index level includes several analysis indexes;

[0046] Obtain the demand side's demand for manufacturing information to build an evaluation model, and match the demand with the analysis indicators in the analysis index database step by step, filter or rebuild the analysis index level of the demand side and the analysis index of each analysis index level , and store the newly added analysis index in the analysis index database;

[0047] Perform pairwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com