Low-voltage energy-saving equipment

An energy-saving equipment and low-voltage technology, which is applied in the field of energy-saving equipment, can solve problems such as short circuit between phases or intermittent discharge, poor contact points, and narrow space, so as to prevent insufficient bonding force, avoid gas non-circulation, and enhance bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

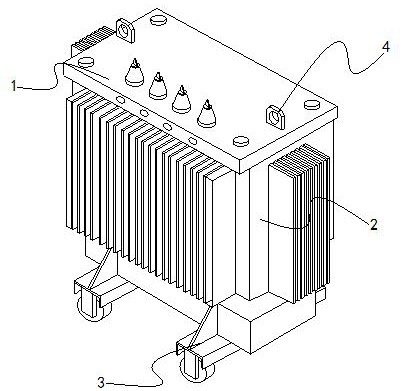

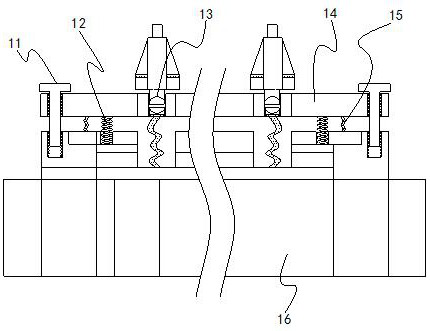

[0023] Such as Figure 1-Figure 5 Shown:

[0024] A low-voltage energy-saving device of the present invention, its structure includes a connection mechanism 1, a transformer 2, a slider 3, and a fixed lifting lug 4, the fixed lifting lug 4 is welded on the surface of the connection mechanism 1, and the transformer 2 is installed on the connection mechanism 1 The lower end of the slider 3 is embedded in the lower end of the transformer 2. The connecting mechanism 1 is provided with a threaded rod 11, a first spring rod 12, a fixing mechanism 13, a connecting plate 14, a folding mechanism 15, and a welding plate 16. The threaded rod 11 runs through the inside of the connecting plate 14, the lower end of the first spring rod 12 is connected to the upper end of the welding plate 16, the fixing mechanism 13 is installed inside the connecting plate 14, and the folding mechanism 15 is installed on the welding plate 16 and embedded in the lower end of the connection plate 14, the wel...

Embodiment 2

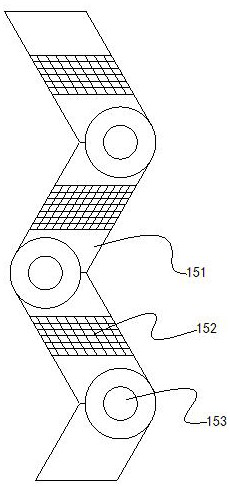

[0031] Such as Figure 6-Figure 7 Shown:

[0032]Wherein, the fixing mechanism 13 is provided with a fixing plate a1, a metal rod a2, a second spring rod a3, a compression plate a4, a bearing a5, a bonding mechanism a6, a rotating rod a7, a circular hole a8, and the second spring rod The lower end of a3 is embedded on the surface of the fixed plate a1, the metal rod a2 runs through the middle of the fixed plate a1, the upper end of the second spring rod a3 is welded to the lower end of the compression plate a4, and the compression plate a4 is connected to the fitting mechanism a6 for clearance fit, the lamination mechanism a6 is installed in the middle of the bearing a5, the outer side of the bearing a5 is embedded in the inside of the rotating rod a7, the circular hole a8 is located above the metal rod a2, and the fixing plate a1 is attached to the inside of the connection plate 14, the middle of the compression plate a4 is a metal sheet, and the surface is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com