Method for cultivating rhizoma paridis

A cultivation method and a technology of re-building, which are applied in planting methods, botanical equipment and methods, cultivation, etc., can solve the problems of solid fertilizers that cannot be evenly distributed and are difficult to absorb quickly, so as to enhance the effective use rate, enhance the flow effect, and promote The effect of effective release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

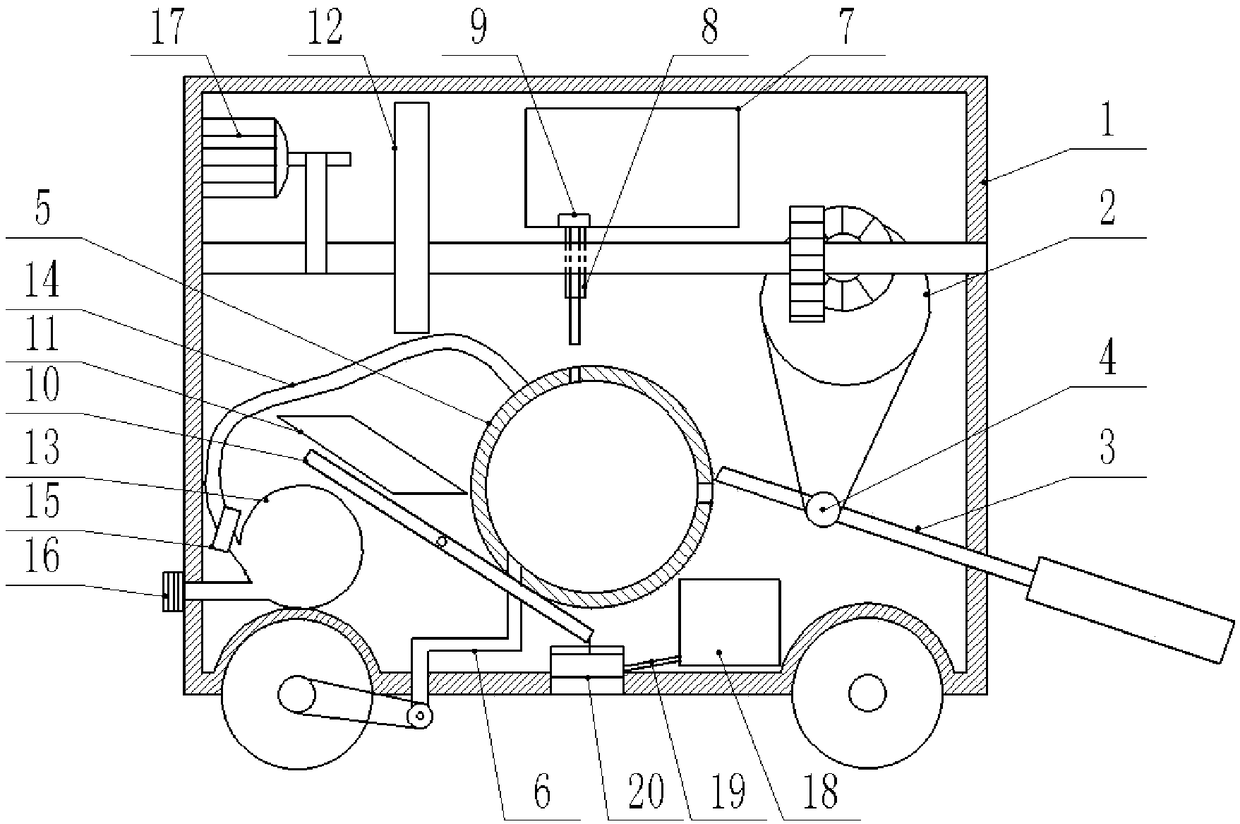

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

[0021] The reference signs in the drawings of the description include: car body 1, eccentric wheel 2, rocking plate 3, belt wheel 4, soil mixing tank 5, soil discharge pipe 6, fertilizer box 7, fertilizer discharge pipe 8, latch 9, lever 10, Wedge 11, cam 12, water bag 13, water spray pipe 14, pressure valve 15, water filling port 16, motor 17, water tank 18, drainpipe 19, plug block 20.

[0022] The cultivation method of Chonglou, the operation steps include:

[0023] 1. Select the land and prepare the soil, and select the sun-sloping area to dig the soil deeply.

[0024] 2. Seed pretreatment, select plump, mildew-free, and non-damaged seeds of P. chinensis, soak and disinfect with carbendazim, and soak the seeds in the nutrient base solution; after soaking, put the seeds in a transparent container Put it in the bag and seal the bag until the seeds are white.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com