Surface-modified light-emitting chip and preparation method thereof

A light-emitting chip and surface modification technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as inability to apply, achieve good luminous uniformity, uniform luminosity or surface illuminance, and reduce visual defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

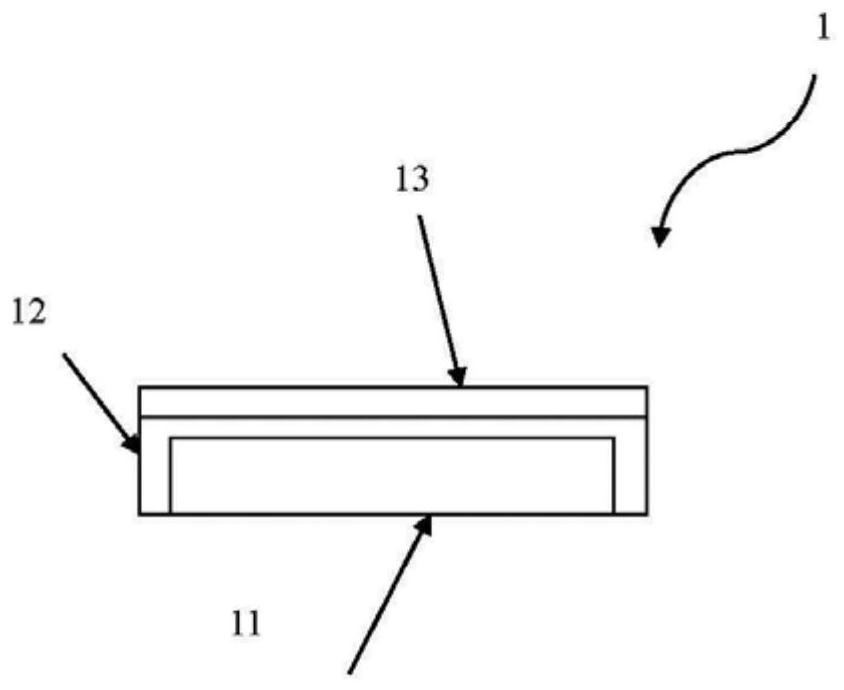

[0021] According to the first embodiment of the present invention, the present invention provides a surface-modified light-emitting chip, which includes a light-emitting chip and a diffusion adhesive layer; and the diffusion adhesive layer covers the front top of the light-emitting chip, thereby forming the described Surface-modified light-emitting chip.

[0022] In one embodiment, the manufacturing implementation of the light-emitting chip includes wafer-level packaging, melting luminescent glue, dispensing, lamination of luminescent film or a combination thereof.

[0023] The following are examples of surface-modified light-emitting chips produced by wafer-level packaging.

[0024] In one embodiment, the wafer-level package is coated with a luminescent powder layer on the surface of the chip.

[0025] In one embodiment, the luminescent powder layer includes polymer glue, silica gel, epoxy resin or a combination thereof

[0026] In one embodiment, the luminescent powder lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com