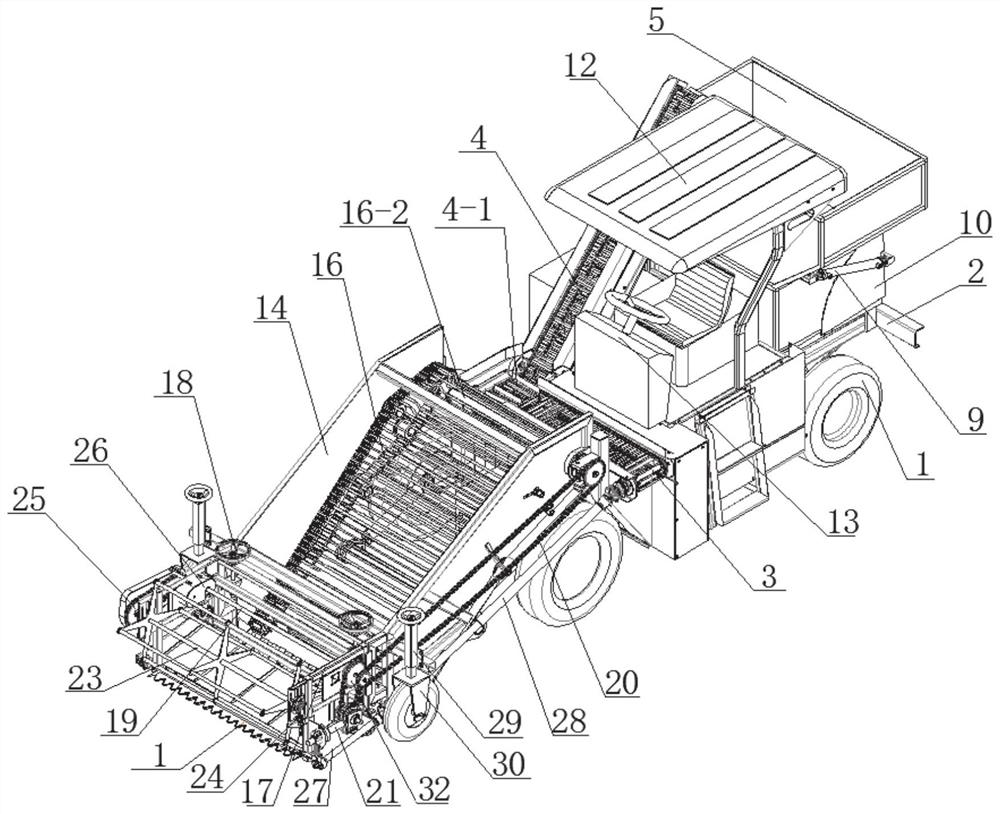

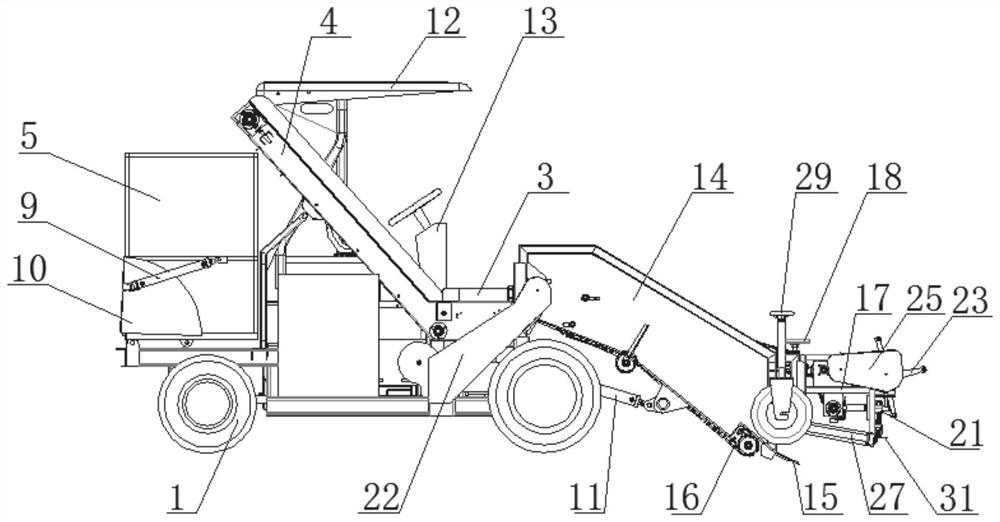

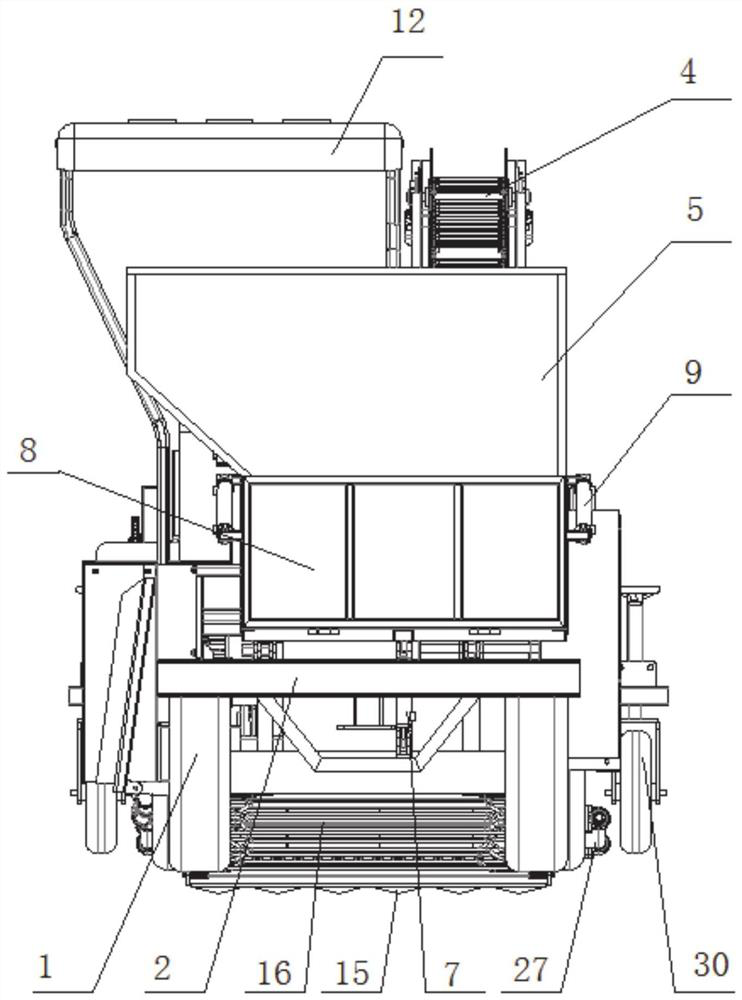

Self-propelled garlic combine harvester and working method

A combine harvester, self-propelled technology, applied in the direction of digging harvesters, harvesters, with rigid working parts, etc., can solve the problems of unfavorable garlic industry stable development, low garlic mechanization rate, low harvesting efficiency, etc., to achieve reduction Drop damage, facilitate collection operations, and ensure the effect of harvesting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0067] This embodiment discloses the working method of the self-propelled garlic combine harvester described in embodiment 1:

[0068]Before work, the staff controls the work of the swing cylinder through the operation control system, puts down the harvesting mechanism, adjusts the height of the depth-limiting wheel through the third lifting adjustment mechanism according to the growth of the garlic to be harvested, completes the adjustment of the excavation depth, and then adjusts the first The lifting adjustment mechanism completes the adjustment of the seedling cutting height, and then adjusts the height of the reel through the second lifting adjustment mechanism to complete the adjustment of the feeding height of the reel. The seedlings are lifted up and moved to the cutting mechanism. The cutting drive mechanism drives the cutting knife to reciprocate in the direction perpendicular to the traveling direction of the car body, and works together with the fixed cutting knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com