Safe discharging tank and application thereof

A safe, material tank technology, applied in liquid separation, chemical instruments and methods, liquid separation auxiliary equipment, etc., can solve the problems of reduced heat transfer effect, no two-phase mixed reaction liquid-material separation device and method, and intensified side reactions. , to achieve the effect of avoiding heat accumulation and avoiding overall thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

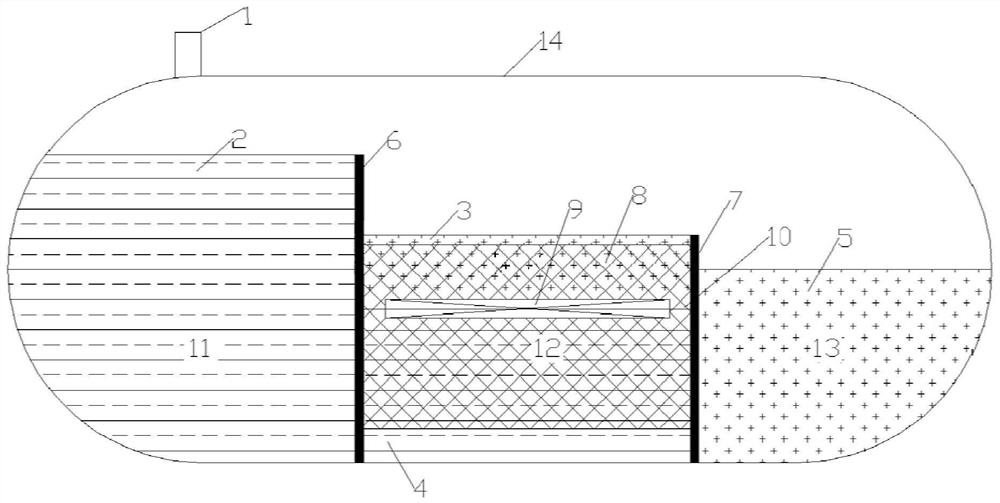

[0063] use as figure 1 The safety discharge tank shown is used for the separation of the acid phase and the organic phase in the reaction liquid feed of the sulfuric acid alkylation process.

[0064] The reaction liquid material contains organic substances such as sulfuric acid and butene, isobutane, and trimethylpentane produced by the reaction of butene and isobutane. Sulfuric acid is immiscible with other organic components, and its density is greater than other organic components. In the reaction liquid material, sulfuric acid is used as the first phase (also called acid phase), while other organic components are used as the second phase (also called organic phase).

[0065] The safety discharge tank includes a tank body 14 . A primary separation baffle 6 and a secondary separation baffle 7 are arranged at the lower part of the inside of the tank body 14, thereby dividing the internal space of the tank body 14 into a first phase zone 11 and a mixed phase zone 12 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com