Device and method capable of achieving continuous and efficient cleaning of inner wall of furnace body

A cleaning furnace, high-efficiency technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., to achieve the effects of easy disassembly, ingenious design, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

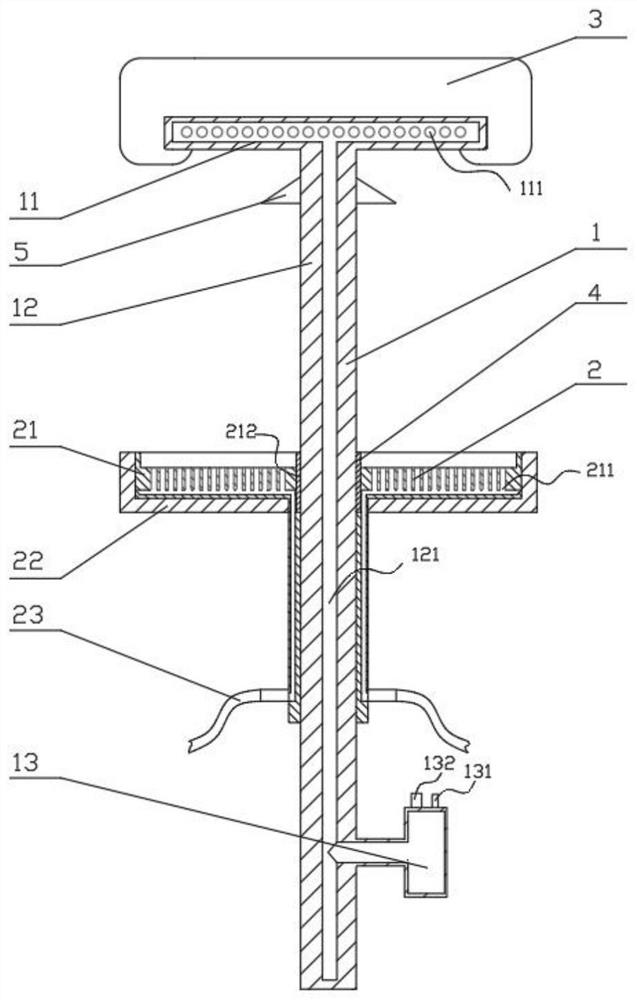

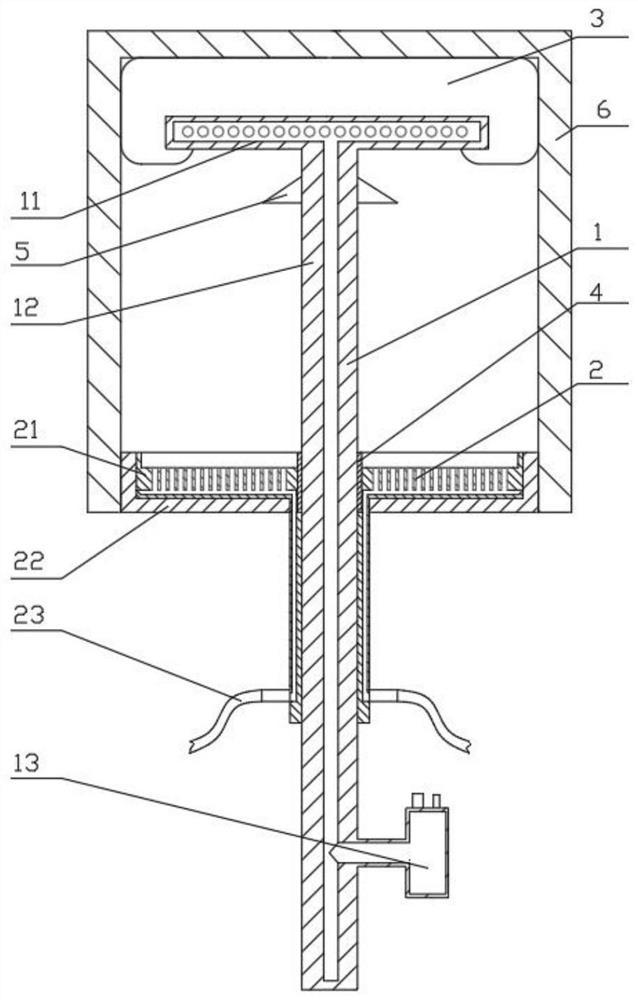

[0032] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a device that can continuously and efficiently clean the inner wall of the furnace in this embodiment includes a liquid outlet device 1, a sealed collection device 2 and a cleaning head 3, the cleaning head 3 is covered and installed on the top of the liquid outlet device 1, sealed The collection device 2 is slidingly installed in the middle of the liquid outlet device 1, and a sealing ring 4 is arranged between the liquid outlet device 1 and the sealing collection device 2. The sealing collection device 2 is installed at the furnace mouth of the furnace body 6 to be cleaned, and the liquid outlet device is moved and rotated. 1, the cleaning head 3 can be controlled to clean the inside of the furnace body 6 to be cleaned.

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, based on specific embodiment one, a device that can continuously and efficiently clean the inner wall of the furnace in this embodiment, the liquid outlet device 1 includes a liquid outlet plate 11, a rotating rod 12 and a liquid storage tank 13, the rotating rod The upper end of 12 is equipped with a liquid outlet plate 11, a plurality of liquid outlet holes 111 are processed on the liquid outlet plate 11, a drainage channel 121 is processed inside the rotating rod 12, a liquid storage tank 13 is installed on one side of the rotating rod 12, and the liquid storage tank 13 passes through The drainage channel 121 inside the rotating rod 12 communicates with the liquid outlet hole 111 on the liquid outlet plate 11, and the liquid storage tank 13 is processed with a pressurization port 131 and a liquid filling port 132, aiming at different deposited impurities, through the liquid fill...

specific Embodiment approach 3

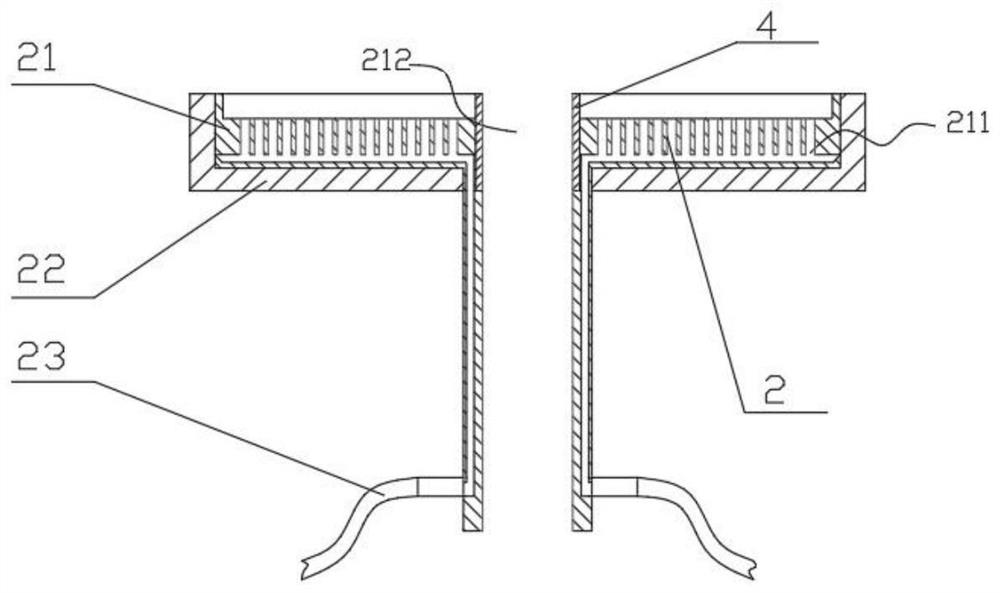

[0034] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, based on the specific embodiment 1, a device that can continuously and efficiently clean the inner wall of the furnace in this embodiment, the sealing collection device 2 includes a waste liquid tray 21, a sealing sleeve 22 and a waste liquid drainage pipe 23, the waste liquid A sealing sleeve 22 is installed on the outer side of the liquid tray 21, and a limiting through hole 212 is processed at the center of the waste liquid tray 21, the rotating rod 12 is installed in the limiting through hole 212, and a sealing ring is arranged between the rotating rod 12 and the limiting through hole 212 4. A waste liquid drainage groove 211 is processed on the waste liquid tray 21. The waste liquid drainage groove 211 is connected and installed with the waste liquid drainage pipe 23. The waste liquid tray 21 is used to collect the cleaning reagents used after cleaning and pass through the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com