Machining die for pressure sensor

A technology for pressure sensors and processing molds, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of slow heat dissipation progress and difficult removal of the shell, and achieve the effect of improving production efficiency, simple structure, and speeding up heat dissipation progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

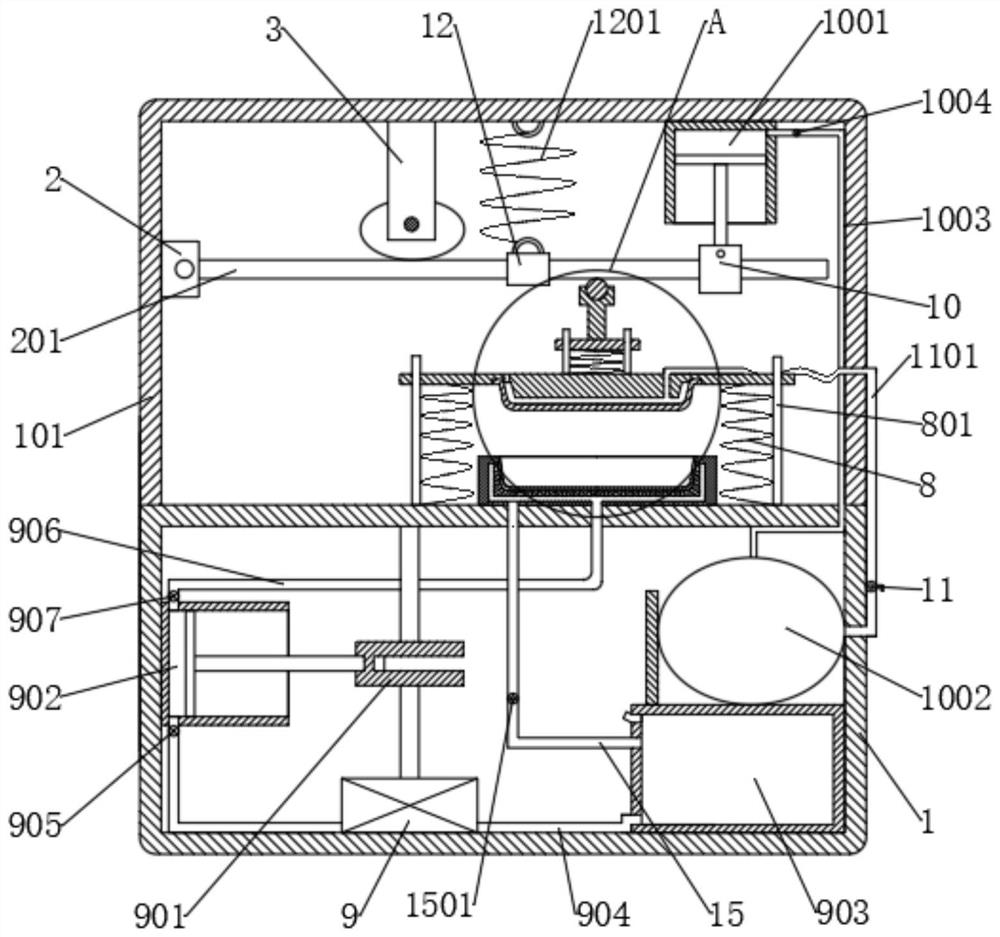

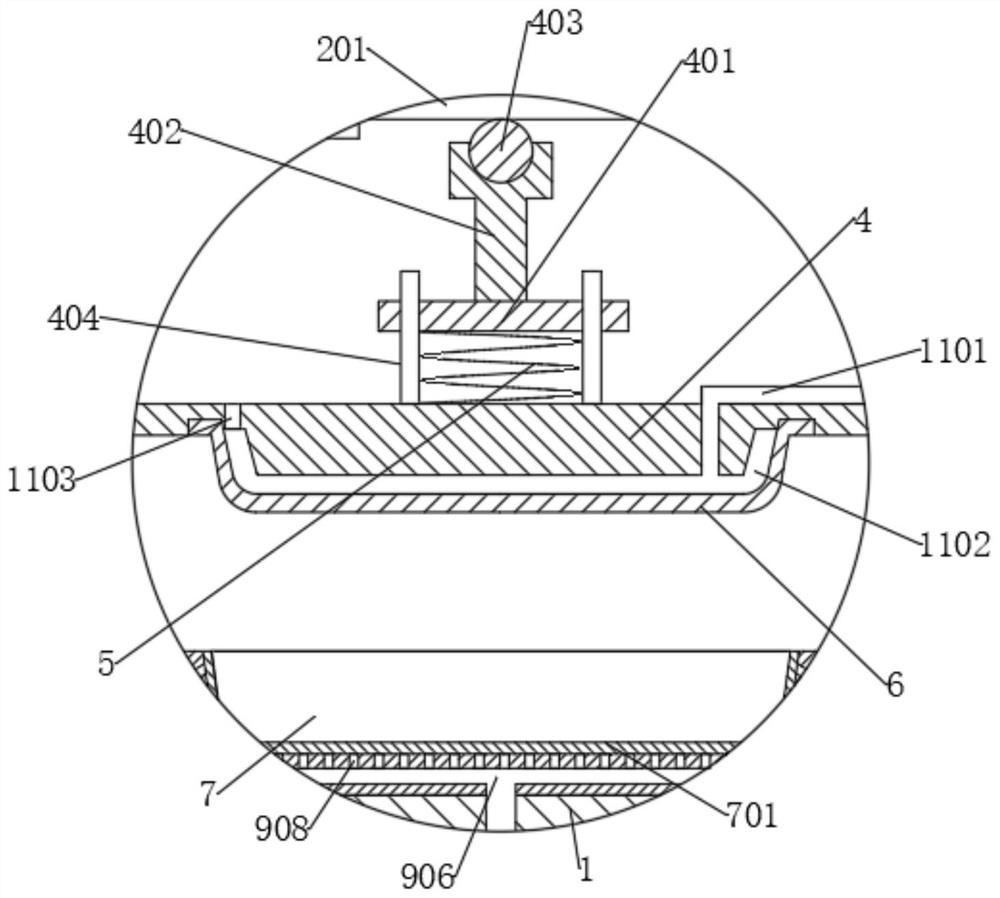

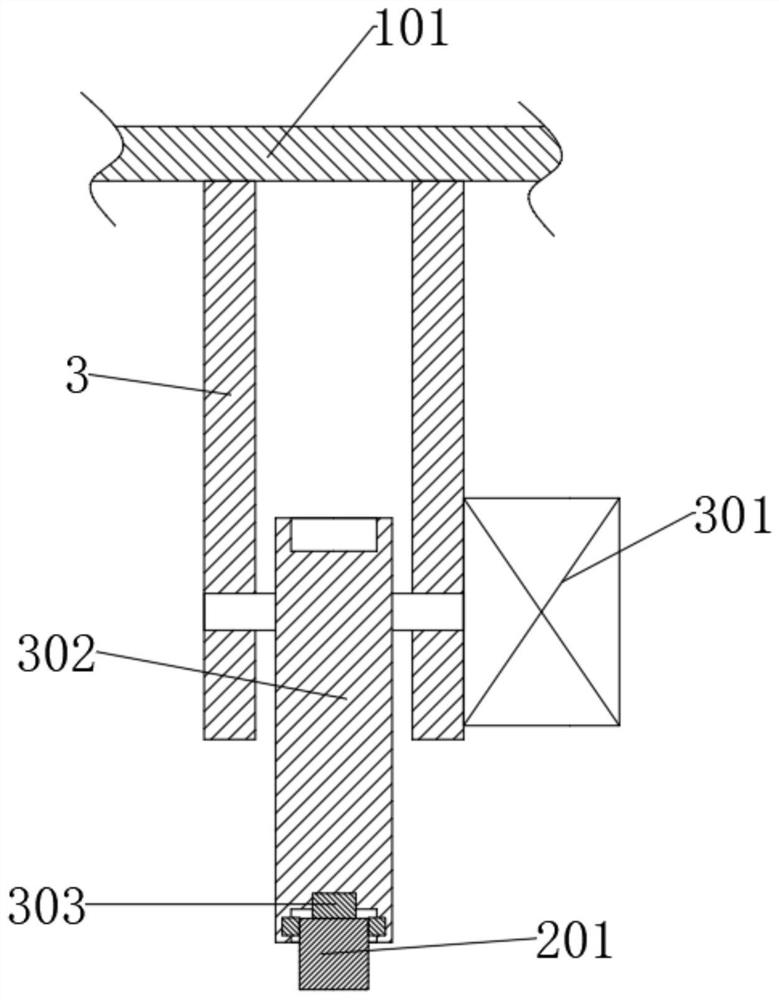

[0027] refer to Figure 1-4 , a processing mold for a pressure sensor, comprising a first box body 1 and a second box body 101, the second box body 101 is located at the top of the first box body 1, and a rotating rod 201 is rotatably connected in the second box body 101, the first box body 101 The top of the box body 1 is provided with a second spring 8, and the end of the second spring 8 far away from the first box body 1 is connected with a second connecting plate 4, and the second connecting plate 4 is provided with a push rod 402, and the push rod 402 and the rotating rod 201 Cooperate with each other, the bottom of the second connecting plate 4 is provided with an upper mold 6, the top of the first box 1 is provided with a lower mold 7, the lower mold 7 is provided with oil paper 701, and the first box 1 is respectively provided with a second motor 9, The first piston 902 and the oil tank 903, the output end of the second motor 9 is connected to the crankshaft 901, the c...

Embodiment 2

[0039] refer to Figure 1-4 , a processing mold for a pressure sensor, comprising a first box body 1 and a second box body 101, the second box body 101 is located at the top of the first box body 1, and a rotating rod 201 is rotatably connected in the second box body 101, the first box body 101 The top of the box body 1 is provided with a second spring 8, and the end of the second spring 8 far away from the first box body 1 is connected with a second connecting plate 4, and the second connecting plate 4 is provided with a push rod 402, and the push rod 402 and the rotating rod 201 Cooperate with each other, the bottom of the second connecting plate 4 is provided with an upper mold 6, the top of the first box 1 is provided with a lower mold 7, the lower mold 7 is provided with oil paper 701, and the first box 1 is respectively provided with a second motor 9, The first piston 902 and the oil tank 903, the output end of the second motor 9 is connected to the crankshaft 901, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com