Portable automatic mobile phone film pasting device and method

A mobile phone film and convenient technology, applied in packaging and other directions, can solve the problems of time-consuming success rate, high price, low price, etc., and achieve the effect of avoiding damage, wide application and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

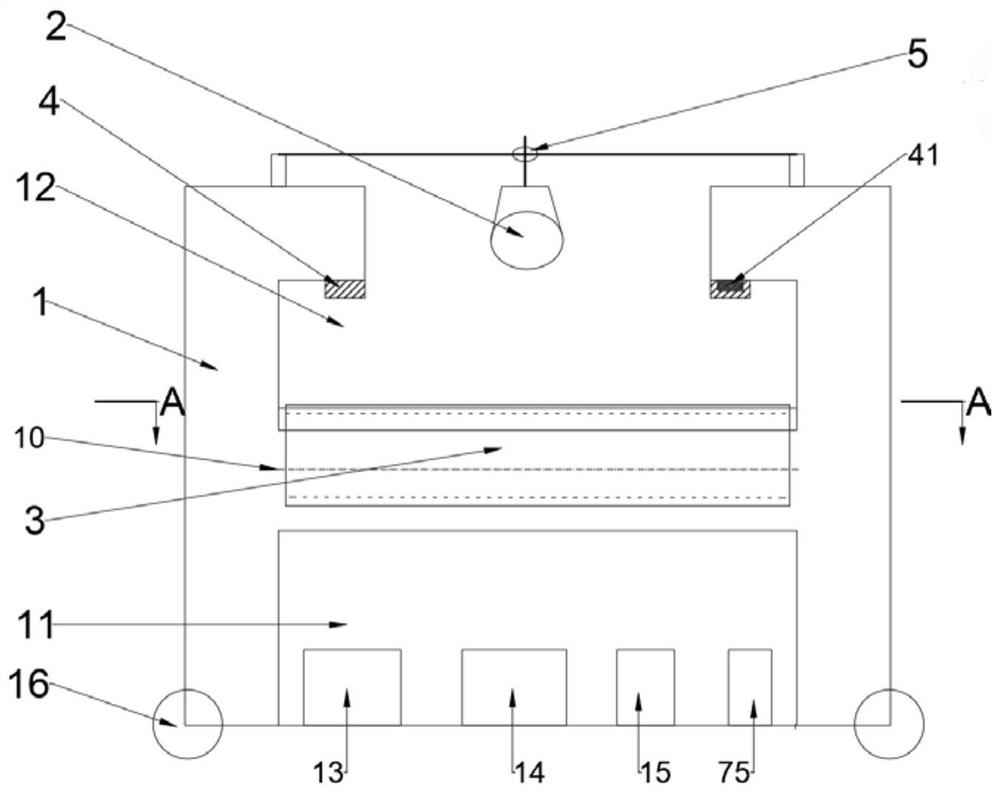

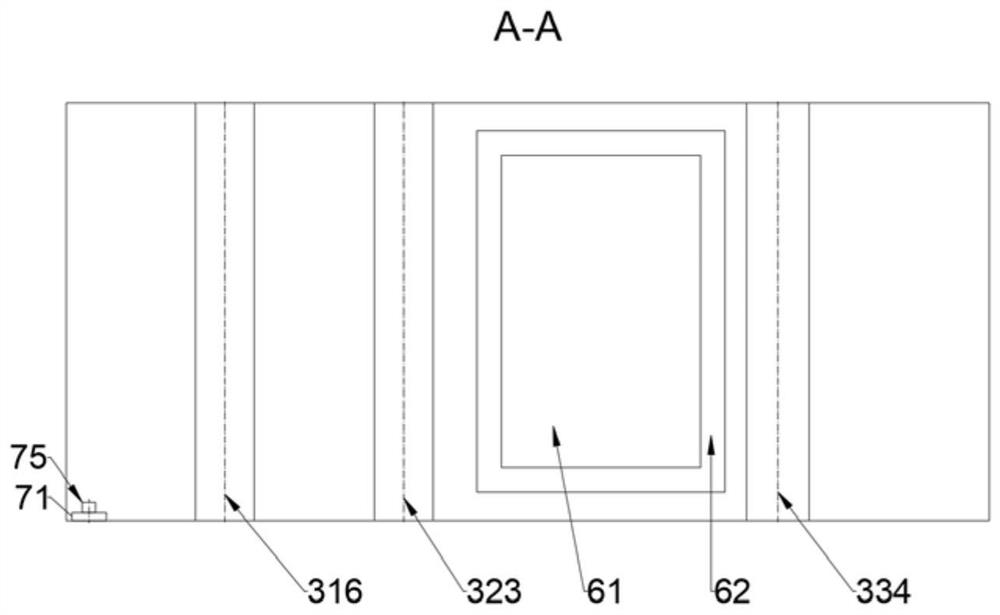

[0062] refer to figure 1 and figure 2 , the invention is a portable automatic mobile phone film sticking device, figure 1 Shown is the left view of the film sticking table 1 of the mobile phone film sticking device, and there are two chambers, namely the power chamber 11 and the working chamber 12, up and down. The work of sticking the film of the mobile phone is mainly completed in the working cavity.

[0063] First, place the mobile phone with the screen facing down and the back facing up on the mobile phone placement area to be pasted on the film sticking table 1 .

[0064] refer to Figure 4 , adjust the Z-axis elevating rod 26 of the mobile phone absorber 2 up and down to ensure that the suction cup 21 can be in close contact with the back of the mobile phone, and the air in the negative pressure sealing box 22 is discharged from the air outlet hole by further squeezing, and the air inlet 23 is sealed at the same time , so that the negative pressure sealing box 22 pr...

Embodiment 2

[0073] refer to Figure 5 The three-axis displacement mechanism 5 of the present invention includes: two Y-axis guide rails, respectively a left Y-axis guide rail 51 , a right Y-axis guide rail 55 , a ball screw 52 and an X-axis guide rod 53 , and a positioning slider 54 .

[0074] The ball screw 52 is installed next to the left Y-axis guide rail 51, and is responsible for pulling the X-axis guide rod 53 to move forward and backward along the Y-axis direction. The rotation of the ball screw 52 makes the X-axis guide rod 53 automatically follow the ball screw. The ball 523 of the bar 52 automatically moves clockwise or counterclockwise along the Y-axis direction guide rails above the left Y-axis guide rail 51 and the right Y-axis guide rail 55 .

[0075] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

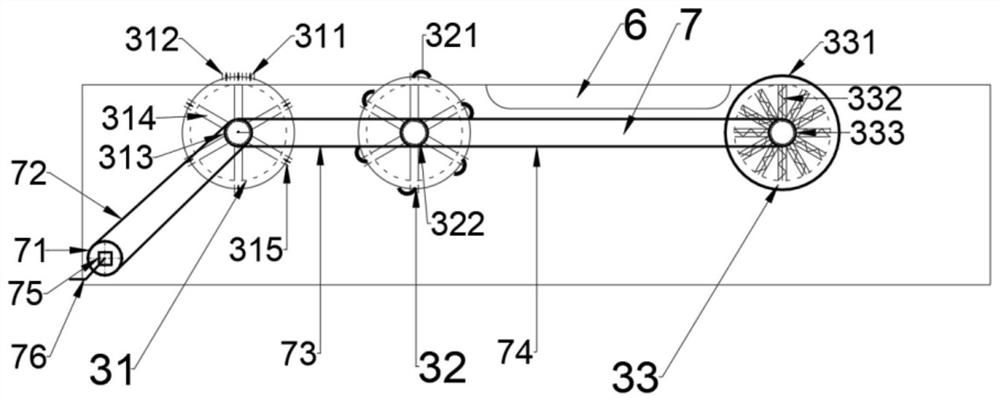

[0077] refer to image 3 , the rotation of the three cylinders of the mobile phone film sticking device according to the present invention can be driven by the motor 75 to drive the driving pulley 71 of the pulley transmission mechanism 7 to start rotating, and then drive the three cylinders to rotate together, or between the three-stage transmission belt A clutch device is installed between them, so that the three rollers can rotate in sequence. Also can go to drive the driving pulley 71 of pulley transmission mechanism 7 to start to rotate by handle rotation, especially when fine-tuning.

[0078] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap