Rotary sealing and cutting device

A rotary and swivel seat technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high manufacturing precision, difficult realization, increased processing difficulty and assembly difficulty, so as to prolong the sealing time and avoid Shock load, effect of ensuring sealing and airtightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

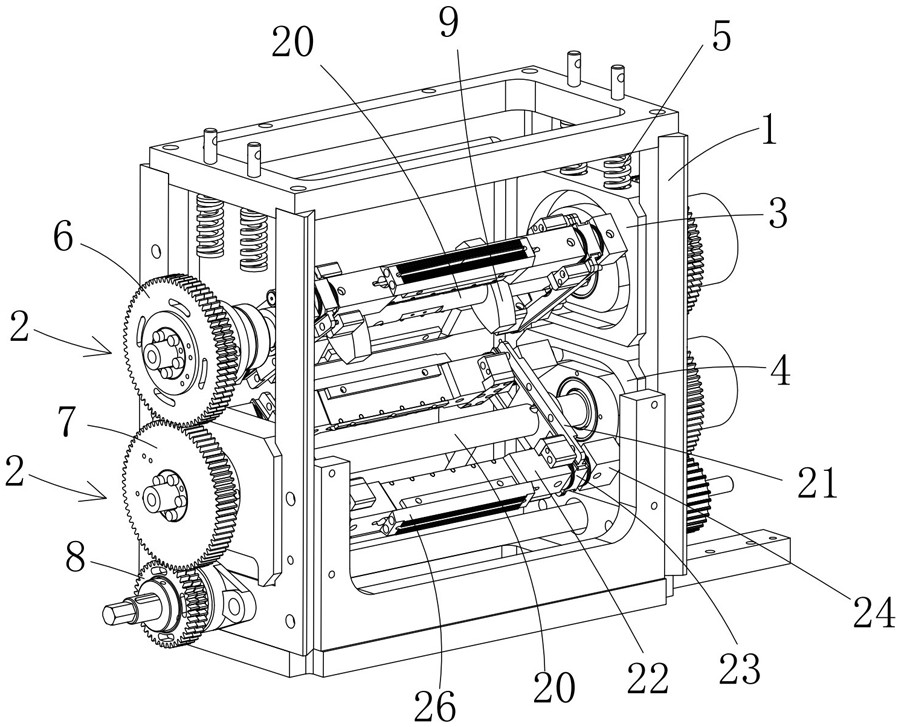

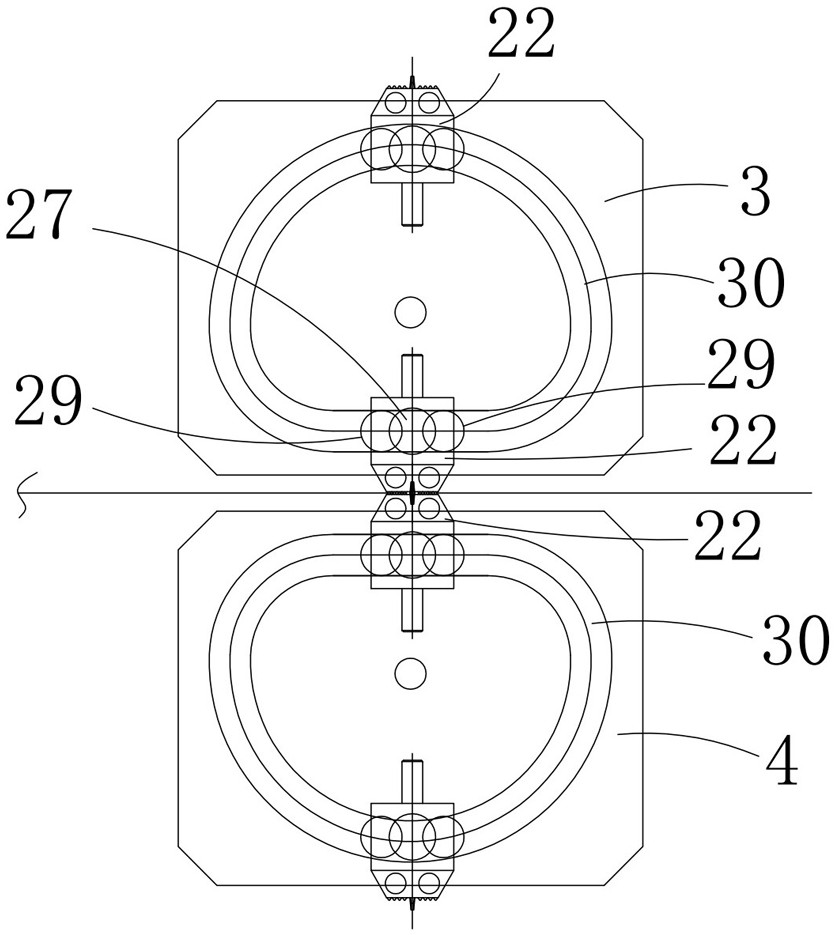

[0021] Such as figure 1 As shown, this rotary sealing and cutting device includes a frame 1 and two upper and lower sealing and cutting mechanisms 2 for sealing and cutting. The horizontally sealed packaging film passes between the upper and lower sealing and cutting mechanisms 2, and is sealed and cut one by one. Individual bags such as Figure 6 shown.

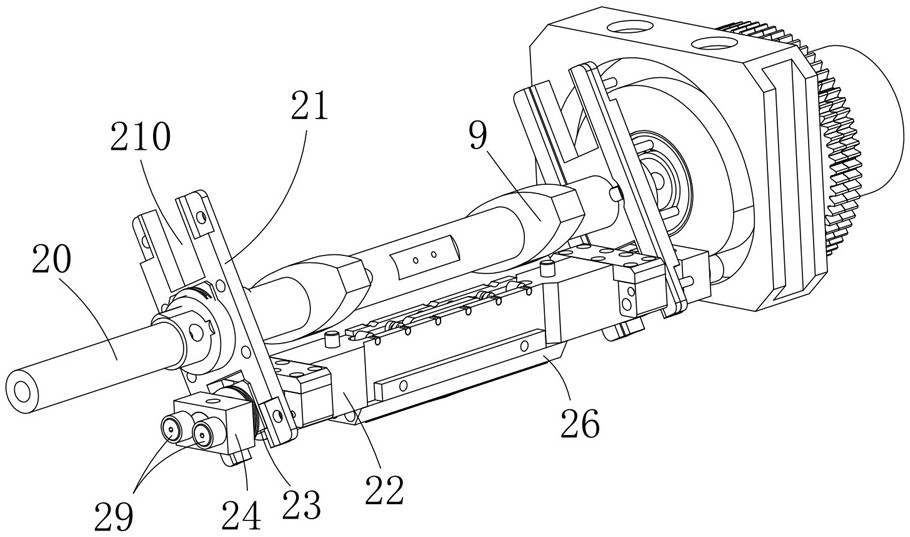

[0022] Such as figure 1 and figure 2 As shown, the sealing and cutting mechanism 2 includes a rotating shaft 20, a rotating base 21 and a sealing and cutting assembly. The rotating base 21 is connected to the rotating shaft 20, and the rotating shaft 20 is connected to the power source that drives the rotating shaft 20. Driven by the power source, the rotating shaft 20 rotates. The rotating seat 21 on the rotating shaft 20 just realizes rotation. The sealing and cutting assembly includes a sealing knife 26 (the sealing knife 26 has a heat cover), a knife seat 22, a slider 23, a guide wheel seat 24 and a guide wheel 29....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com