Material falling method and device

A cutting and material technology, applied in conveyor control devices, loading/unloading, transportation and packaging, etc., can solve problems affecting sinter quality and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

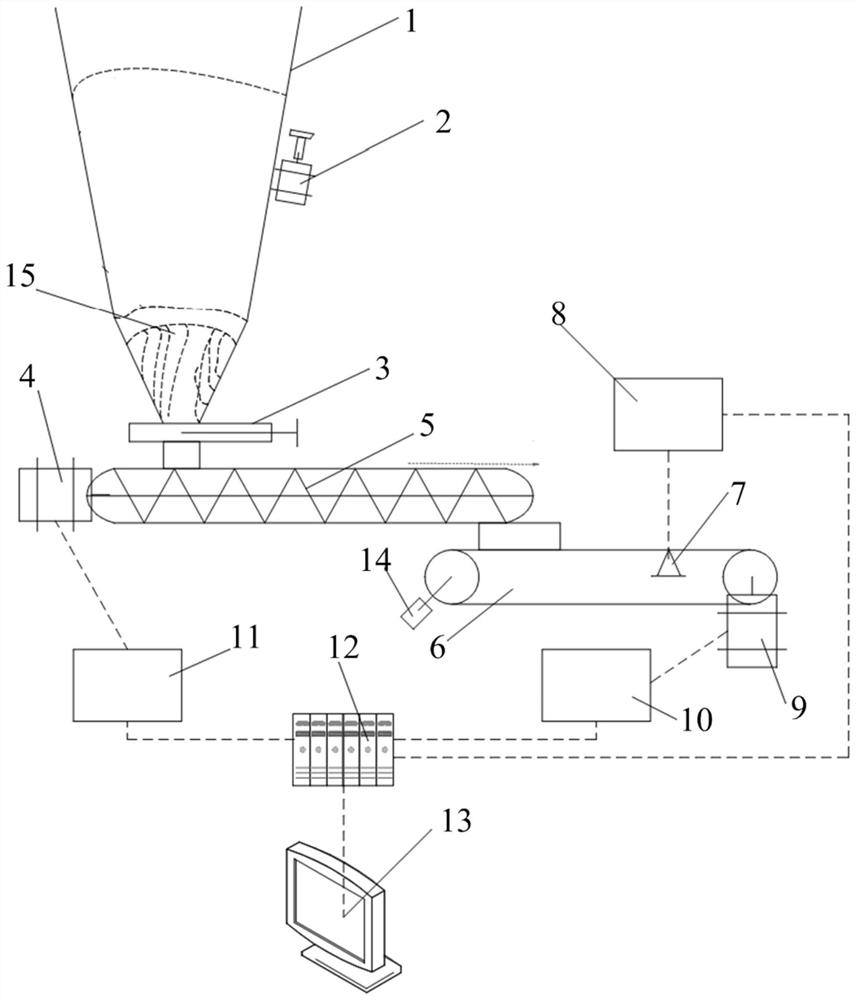

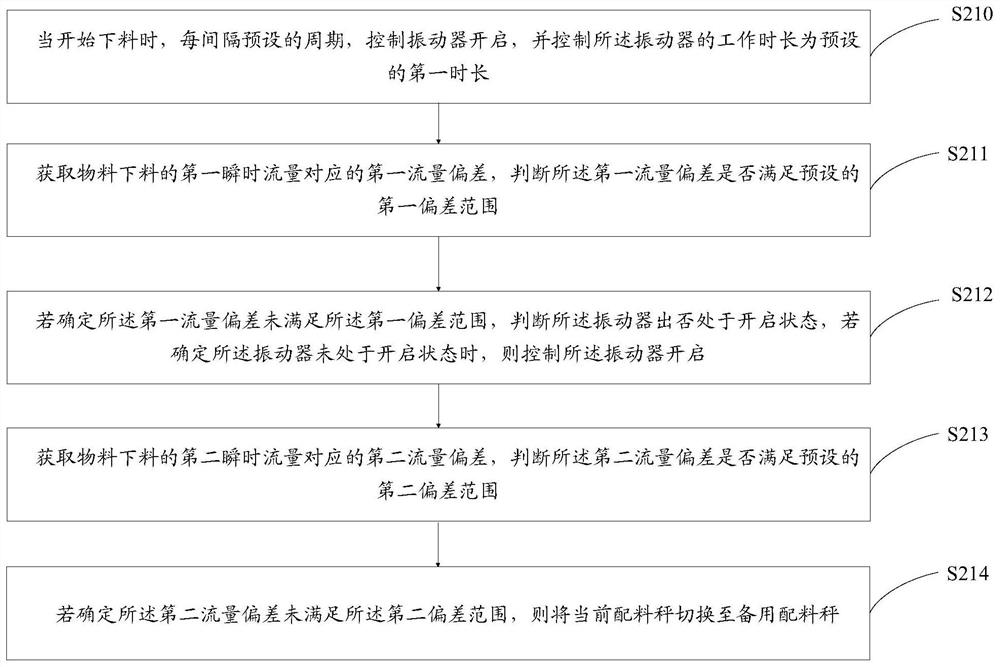

[0045] This embodiment provides a blanking method, which is applied in a blanking mechanism. In order to understand the technical solution of the present invention more clearly, the structure of the blanking mechanism is introduced here. Such as figure 1 As shown, the blanking structure includes: batching ore trough 1, vibrator 2, outlet gate valve 3, screw feeder motor 4, screw feeder 5, belt weighing machine 6, pressure sensor 7, flow meter 8. Belt weighing machine motor 9, belt weighing machine frequency converter 10, screw feeder frequency converter 11, controller 12, upper computer 13 and speed sensor 14; among them,

[0046]The batching trough 1 is used for loading materials, and the materials can be powder materials such as quicklime. Due to the characteristics of this material, it is easy to have the phenomenon of material accumulation and fluffing. The discharge port gate valve 3 is installed below the batching ore tank 1, and is used to control the flow of material ...

Embodiment 2

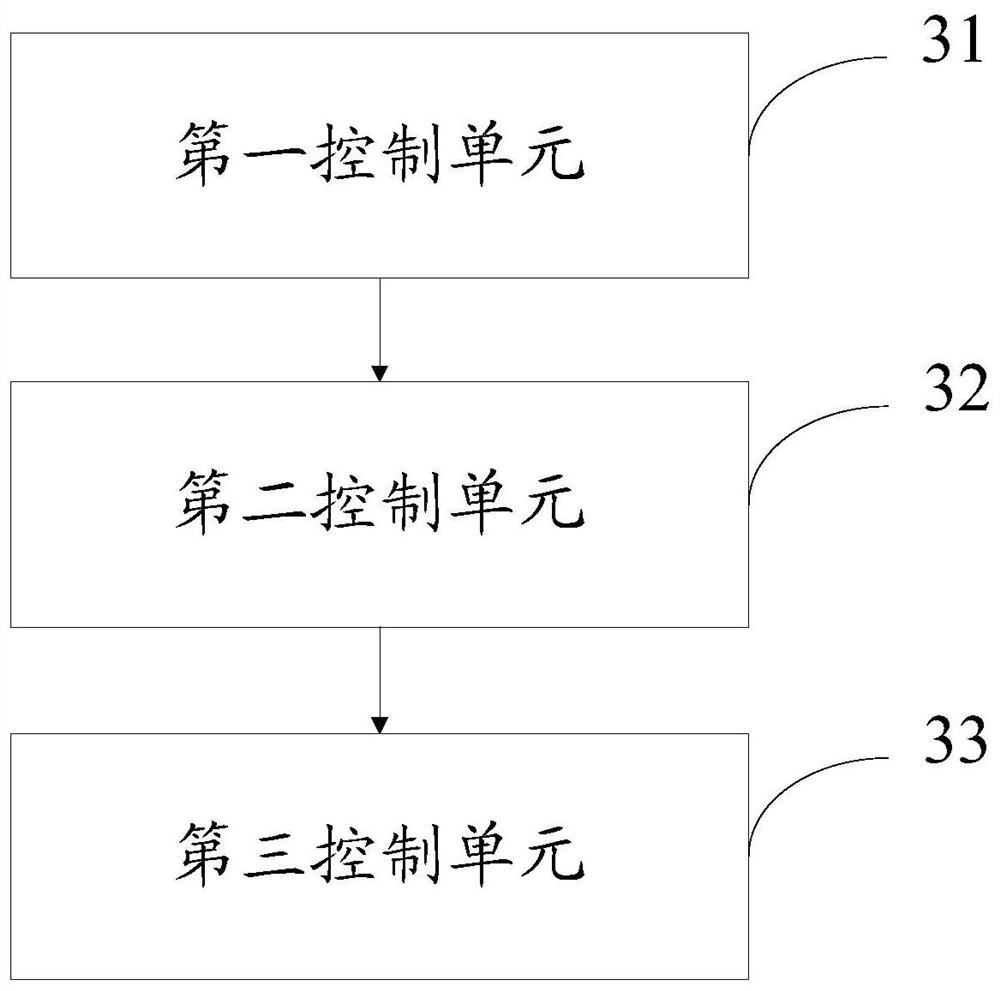

[0079] This embodiment provides a blanking device, such as image 3 As shown, the device includes: a first control unit 31, a second control unit 32 and a third control unit 33; wherein,

[0080] The first control unit 31 is used to control the opening of the vibrator at intervals of a preset period when starting to unload, and control the working duration of the vibrator to be the preset first duration;

[0081] The second control unit 32 is used to obtain the first flow deviation corresponding to the first instantaneous flow rate of material discharge, and judge whether the first flow deviation satisfies the preset first deviation range; if the first flow deviation is determined If the first deviation range is not met, it is judged whether the vibrator is in the open state, and if it is determined that the vibrator is not in the open state, then control the vibrator to be open;

[0082] The third control unit 33 is used to obtain the second flow deviation corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com