Textile machine

A textile machine and spinning technology, applied in the field of spinning cover, can solve problems such as affecting the quality of yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

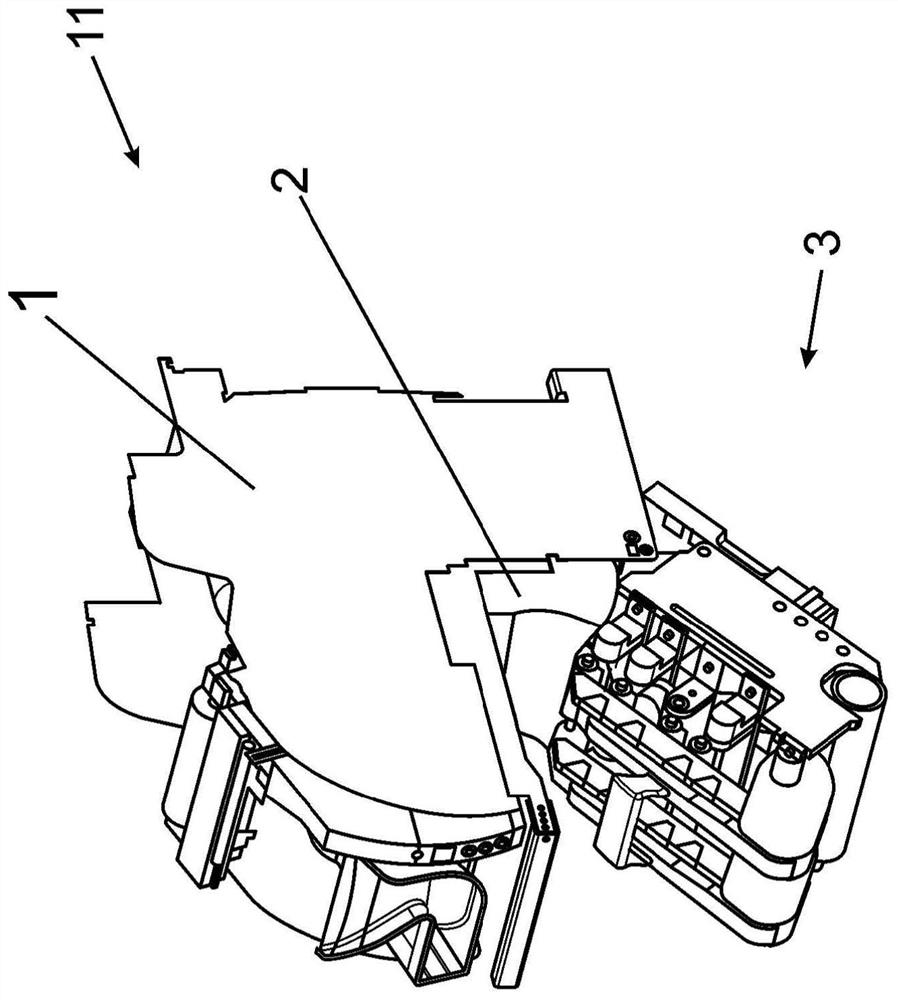

[0044] exist figure 1 A spinning device 11 of a textile machine (not shown here) having a spinning unit designed as an air spinning unit 1 is shown in FIG. The strand-shaped fiber material, not shown here, is conveyed to the inlet of the spinning nozzle by means of the delivery roller pair of the drafting device 3 of the spinning device 11, which is arranged in the spinning direction in front of the spinning nozzle of the air spinning unit 1. And from there it is sucked or sucked in by negative pressure.

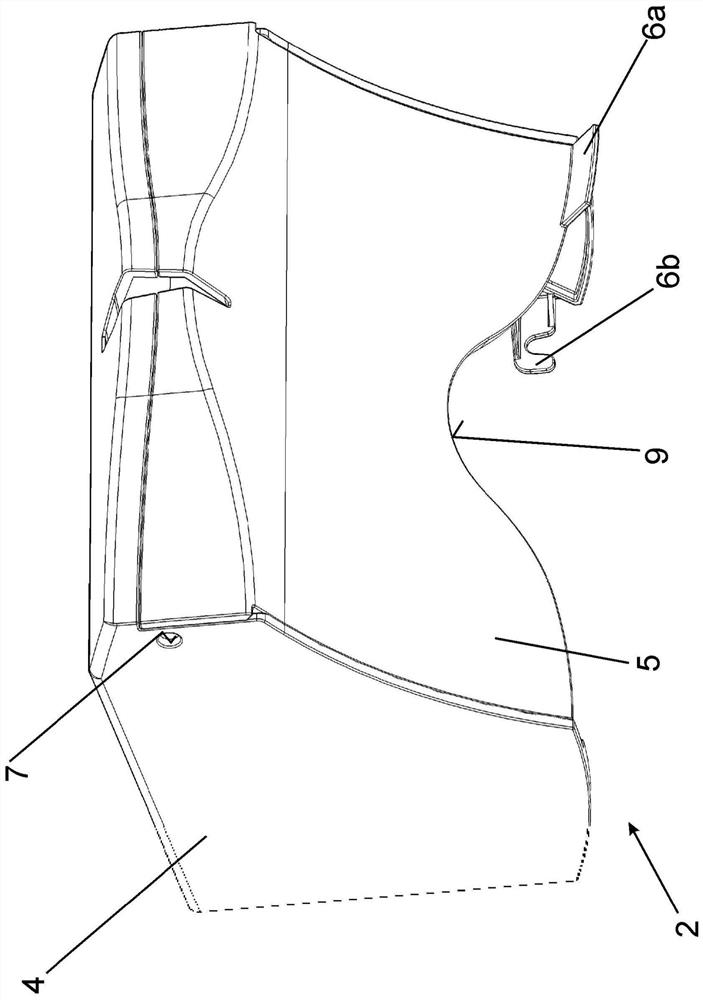

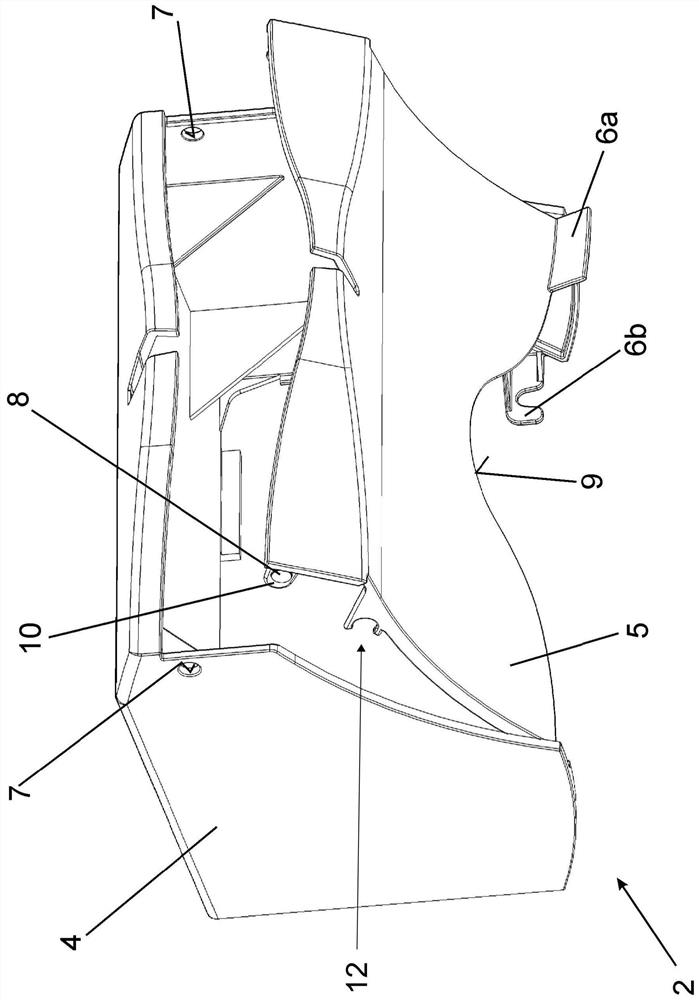

[0045] The spinning hood 2 of the spinning device 11 in the working position is arranged in the region between the drafting device 3 and the rotor spinning unit 1 . The spinning hood 2 delimits the spinning space around the inlet with respect to the surroundings, where the spinning hood adjoins the drafting device 3 and the rotor spinning unit 1 for this purpose without hindering the fiber sliver from the drafting device 3 was sent into the entrance.

[0046] exist figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com