Simple set-out device and using method thereof

A wire-releasing device and a simple technology, which are applied in construction, building construction, and construction material processing, can solve the problems of wire-laying material waste, pollution, and low efficiency, and achieve material waste control, environmental pollution control, production and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

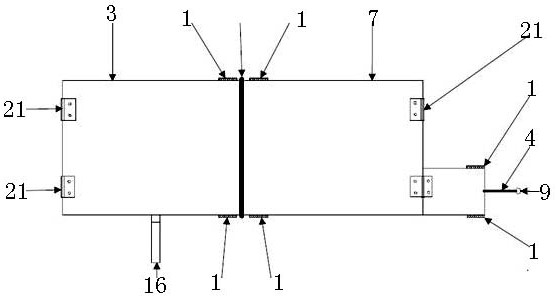

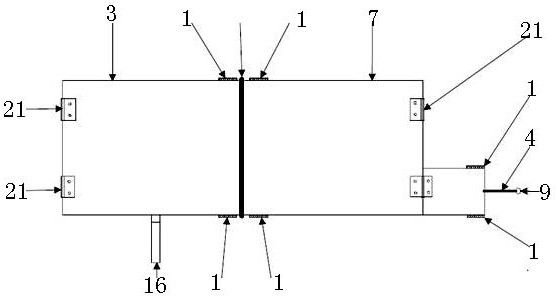

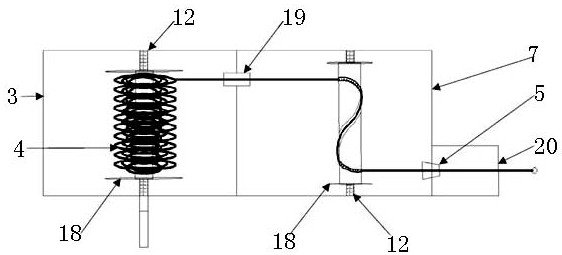

[0036] like Figure 1-6 Shown: a simple pay-off device, which includes cover buckle 1, hatch cover 2, wire cabin 3, wire rope 4, No. 2 core hole 5, box cover 6, ash cabin 7, rope ring 9, hatch 10 , Rolling ash barrel 11, rotating shaft 12, rolling groove 13, handle 15, handle 16, wire wheel 17, baffle plate 18, No. 1 core hole 19, buffer cabin 20, hinge 21;

[0037] The line cabin, ash cabin, and buffer cabin are connected in sequence and integrally formed. No. 1 core hole is provided at the interface panel of the line cabin and the ash cabin, and No. 2 core hole is provided at the interface panel of the ash cabin and buffer cabin;

[0038] There is a rotating shaft in the wire cabin, which is a movable rotating shaft, and a wire wheel is sleeved outside the movable rotating shaft. The rotating shaft and the wire wheel rotate synchronously, and the wire rope is wound on the wire wheel. One end of the rotating shaft extends to the outside of the cabin cabin;

[0039] There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com