Device and method for calibrating magnetic interference of drilling tool

A magnetic interference and drilling tool technology, applied in the direction of measuring devices, instruments, etc., can solve the problem that the directional sensor is affected by the magnetic interference of drilling tools, and achieve the effect of optimizing the drilling tool assembly, improving the measurement accuracy and reducing the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A method for calibrating drilling tool magnetic interference, comprising the following steps:

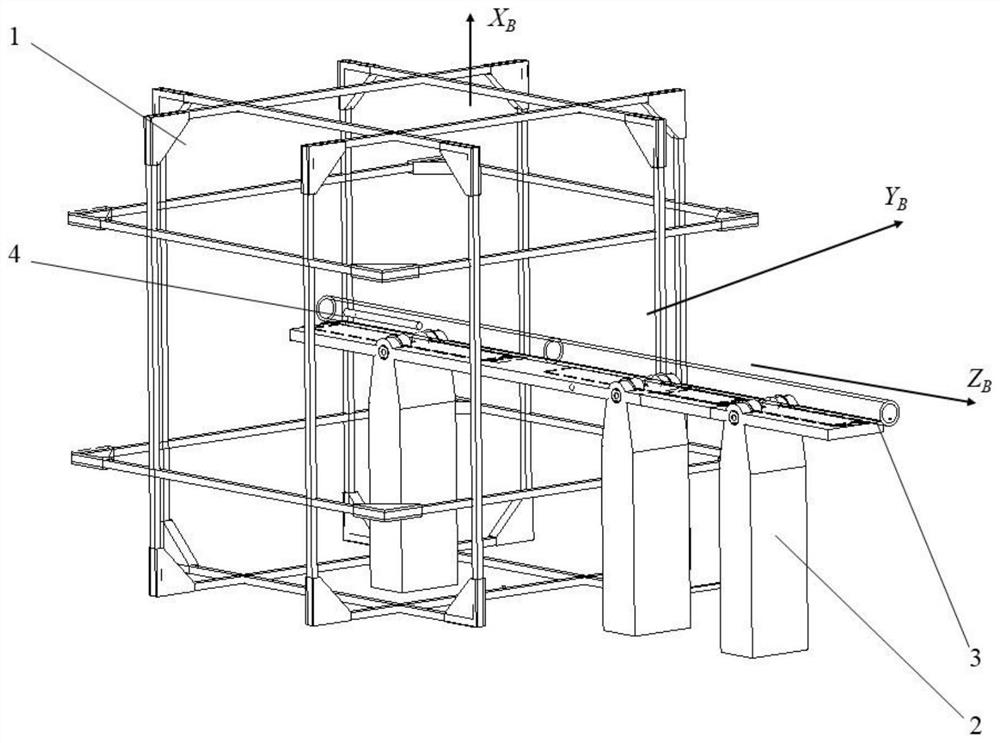

[0041] (1) if figure 1 As shown, adjust the magnetic field value in the three-axis Helmholtz coil 1, adjust the three-axis Helmholtz coil according to the ambient magnetic field strength at the center of the coil, and emit a vector magnetic field X B , Y B ,Z B , to offset the external magnetic field; after the coil center magnetic field value is "0", adjust the vector magnetic field Z B Generate an additional 50μT magnetic field as the standard unit magnetic field;

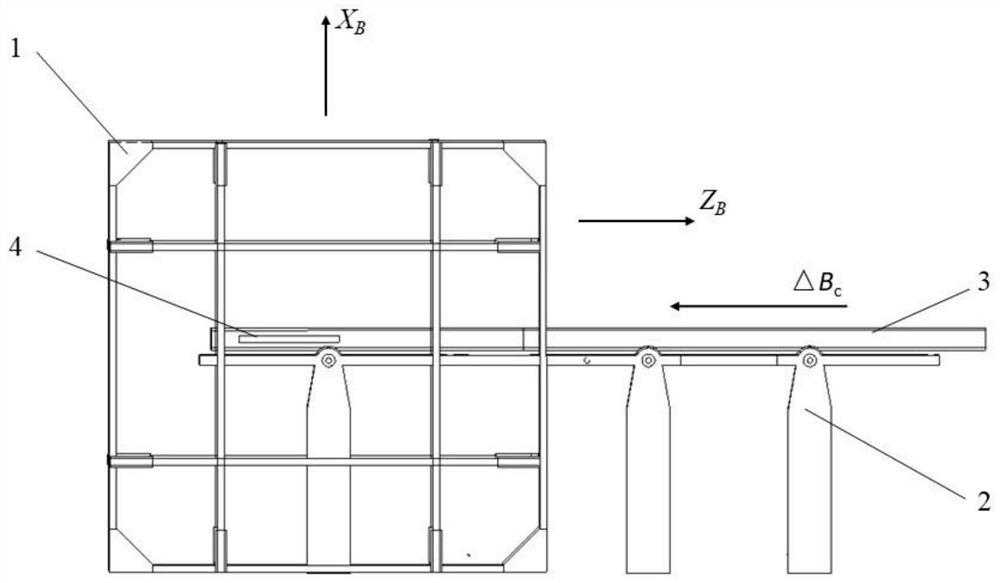

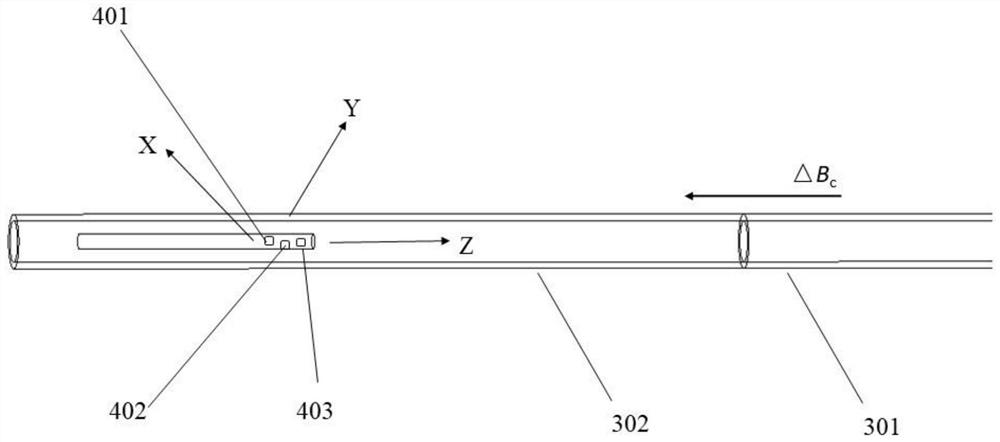

[0042] (2) if figure 2 with image 3 As shown, the drilling tool 3 is fixed inside the triaxial Helmholtz coil 1 by calibrating the slide rail on the stand 2, so that the magnetic sensor B of the orientation sensor 4 inside the non-magnetic drill collar 301 x 401、B y 402 and B z 403 Near the center of the triaxial Helmholtz coil 1 within 40cm×40cm×40cm; relative to B x 401 and B y 402, the disturbance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com