Farmland ditching and ridging device

A farmland and rack technology, applied in agriculture, agricultural machinery and implements, shovels, etc., can solve the problems of low efficiency, inconsistent width and height of field ridges, inconvenient use, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

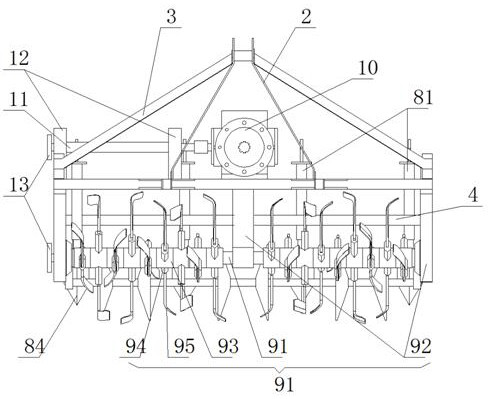

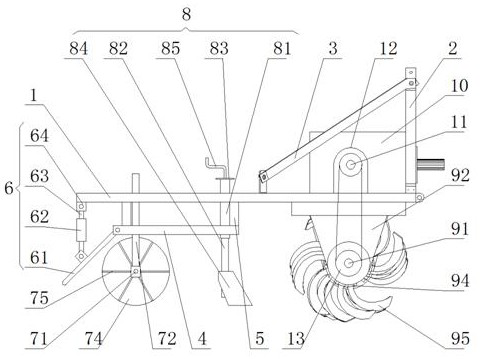

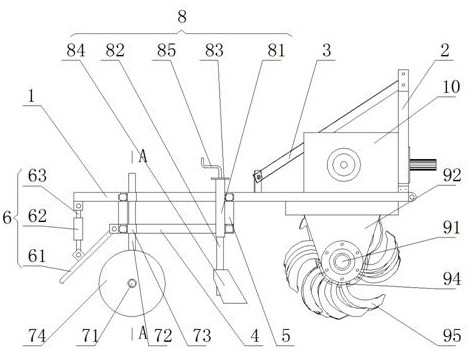

[0024] see Figure 1-4 , the present invention provides a technical solution: a farmland ditching and ridging device, including a frame 1 and a support beam 2 arranged on the top of the frame 1, and the two sides of the support beam 2 are provided with the top surface of the frame 1. The traction beam 3, the top surface of the frame 1 close to the end of the support beam 2 is provided with a reducer 10, the lower part of the reducer 10 is provided with a loosening mechanism 9 installed on the bottom surface of the frame 1, the reducer 10 is connected and drives the unscrewing mechanism 9 The side of the unscrewing mechanism 9 away from the support beam 2 is provided with an underframe 4 connected to the frame 1, and the end of the underframe 4 away from the unscrewing mechanism 9 is hinged with a leveling mechanism 6, and the underframe 4 is provided near the inner side of the leveling mechanism 6. There is a ridging mechanism 7, and the other end of the chassis 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com