A kind of multistage extraction method of essential oil tobacco extract

A technology of tobacco extract and extraction method, applied in the directions of tobacco, tobacco processing, tobacco preparation, etc., can solve problems such as affecting the taste of the product, and achieve the effects of scientific flavor ratio, improving satisfaction, and increasing the aroma of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

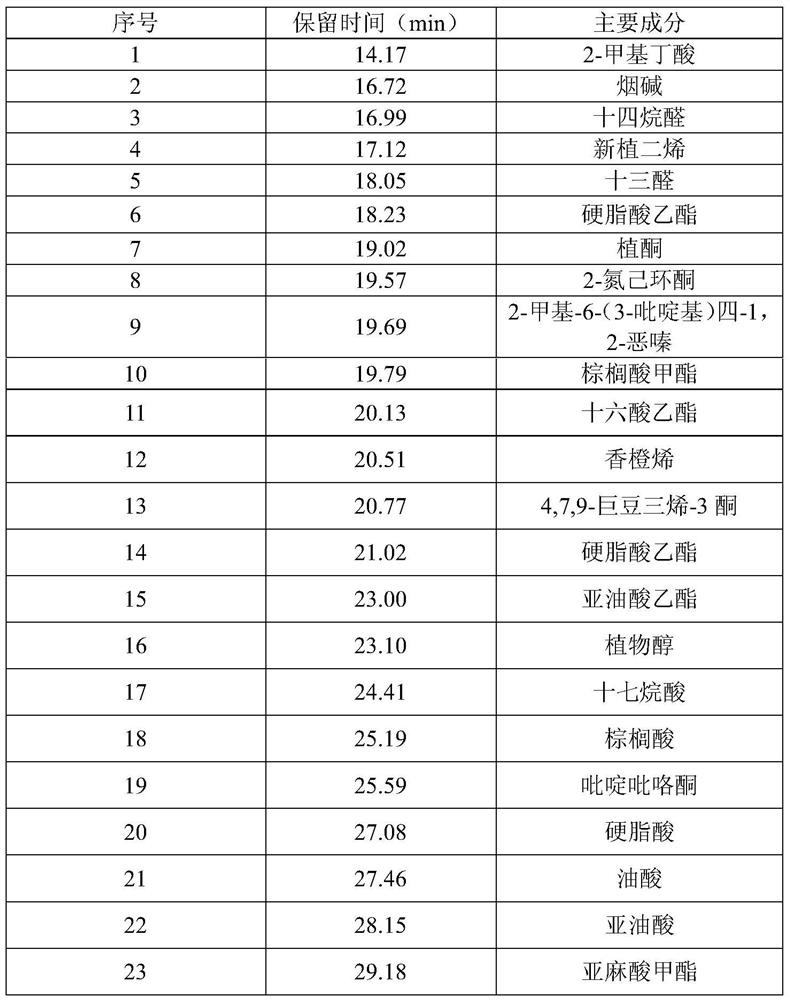

Embodiment 1

[0042] Multi-level extraction method of essential oil tobacco extract, including the following steps:

[0043] S1: Tobacco enzymatic solution; after drying 300 g of Maryland tobacco, cutting the wire, as a cellulase as an enzymatic hydrophilic water, adding water into an enzymatic solution, use a compressed air spray pump to uniformly spray the above-mentioned enzymatic solution onto a tobacco raw material, then The tobacco raw materials sprayed over the enzymatic hydrolytic raw material were placed in a sealed enzymatic synthesis, and the enzymatic solution was foundated under 45 ° C. After the enzymatic solution is completed, the enzyme loss treatment is performed, and the temperature of the regulatory enzyme solution is 85 ° C. After 15 min, the temperature in the enzyme solution can slowly fall back to the normal temperature to obtain an enzymatic tobacco raw material;

[0044] S2: Ultrasound extraction: Three ultrasound extraction, including:

[0045] Optical extraction; afte...

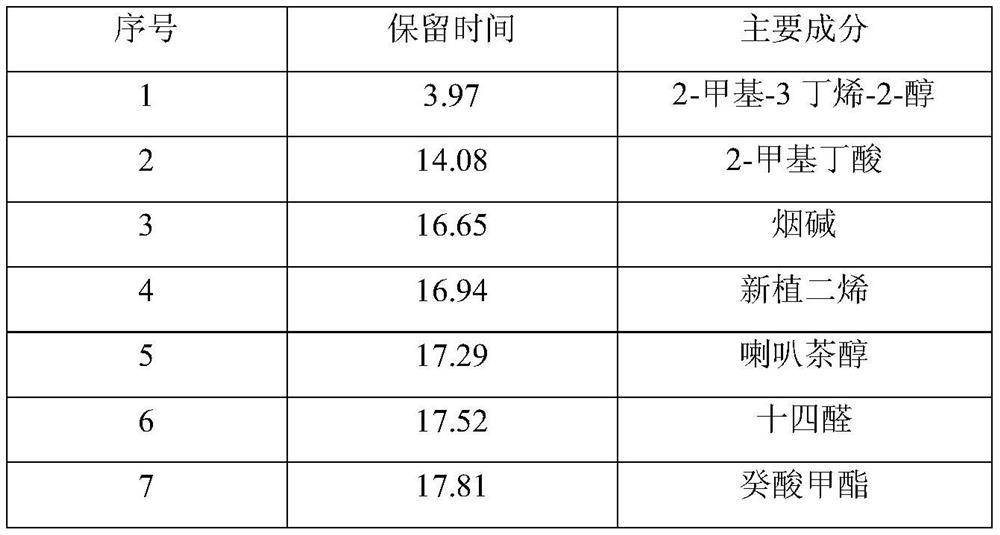

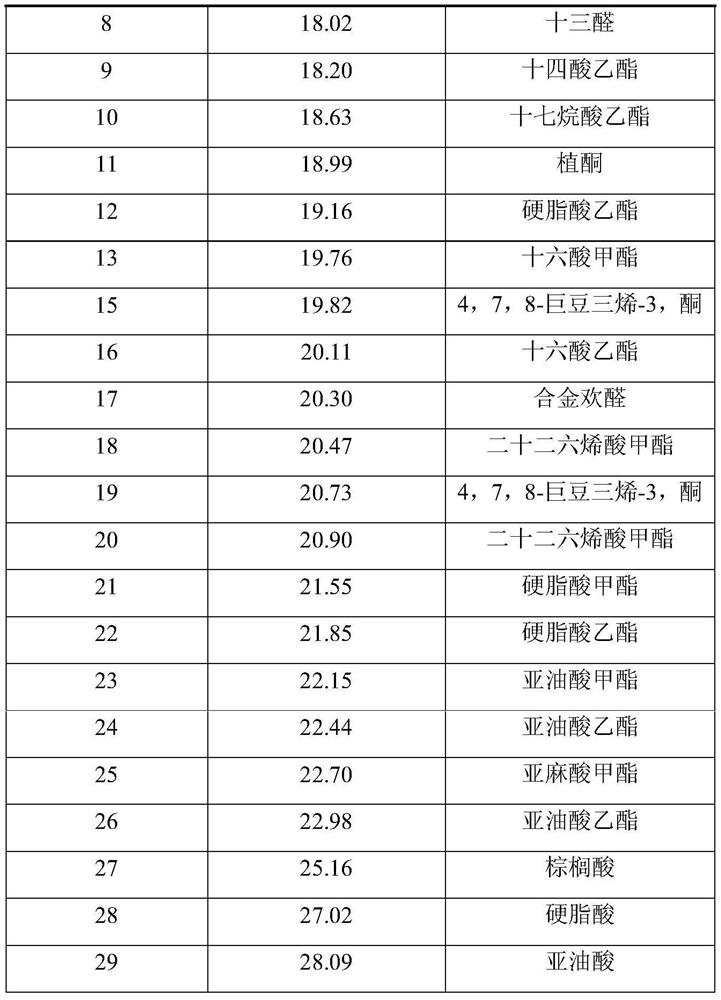

Embodiment 2

[0057] Multi-level extraction method of essential oil tobacco extract, including the following steps:

[0058] S1: Tobacco enzymatic solution: 300 g of white ribbed tobacco drying after drying treatment, with cellulase, pectin cleavage enzyme and amylase as enzymatic hydrolysis, add water to an enzymatic solution, using a compressed air spray pump The enzymatic hydrolyzate is uniformly sprayed onto the tobacco raw material, and then the tobacco raw material sprayed through the enzymatic hydrolysis raw material is placed in a sealed enzymatic synthesis, and the enzymatic solution is 13 h under 40 ° C. After the enzymatic solution is completed, the enzyme loss treatment is performed, and the temperature of the regulatory enzyme solution is 65 ° C, after 30min, the temperature of the enzyme solution can slowly fall back to the normal temperature to obtain an enzymatic toxacite raw material;

[0059] S2: Four ultrasound extraction, including:

[0060] Extraction of ultrasound: After p...

Embodiment 3

[0071] Multi-level extraction method of essential oil tobacco extract, including the following steps:

[0072] S1: Tobacco enzymatic solution: After mixing 150 g of flue-cured tobacco and 150g drying tobacco, cutting the wire, taking cellulase, esterase, protease, and lignozyme as an enzymatic hydrolysis, add water to an enzymatic solution, and the above enzyme The solution is uniformly sprayed onto the tobacco raw material, and then the tobacco raw material sprayed through the enzymatic solution is placed in a sealed enzymatic solution, and the enzymatic solution is found in 48 ° C. After the enzymatic solution is completed, the enzyme loss treatment is performed, and the temperature of the regulatory enzyme solution is 73 ° C, after remained 25min, slowly drop the temperature of the enzyme solution to the normal temperature to obtain an enzymatic tobacco raw material;

[0073] S2: Three ultrasound extraction, the method is as follows:

[0074]Ultrasonic first extraction: After h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com