A preparation method of temperature-responsive bacterial cellulose antibacterial nanogel

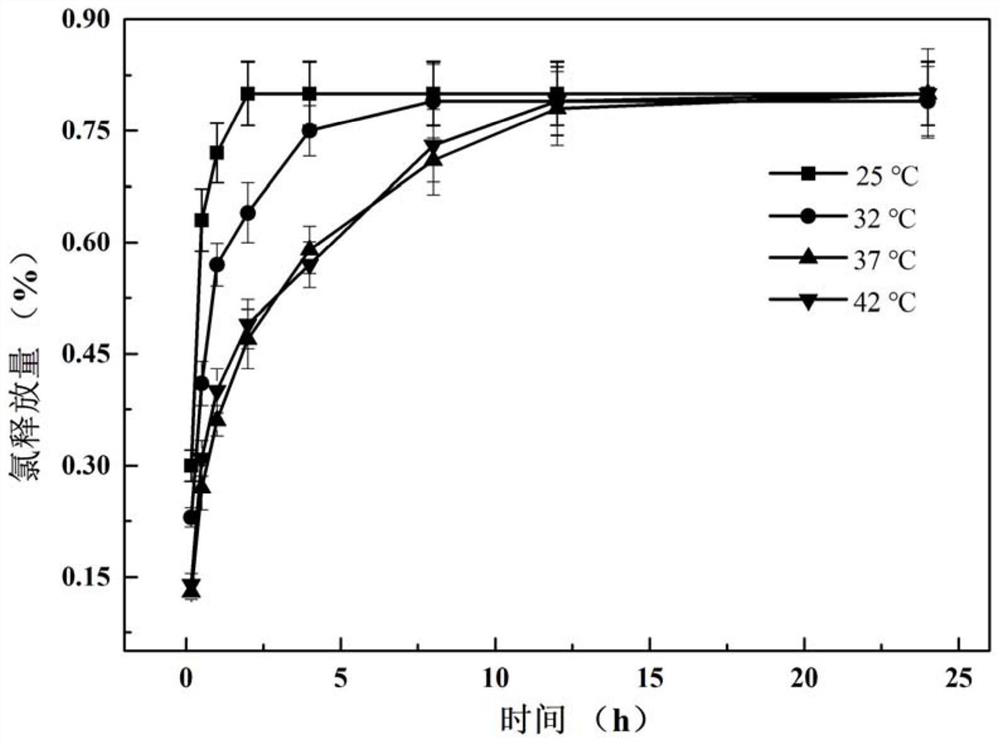

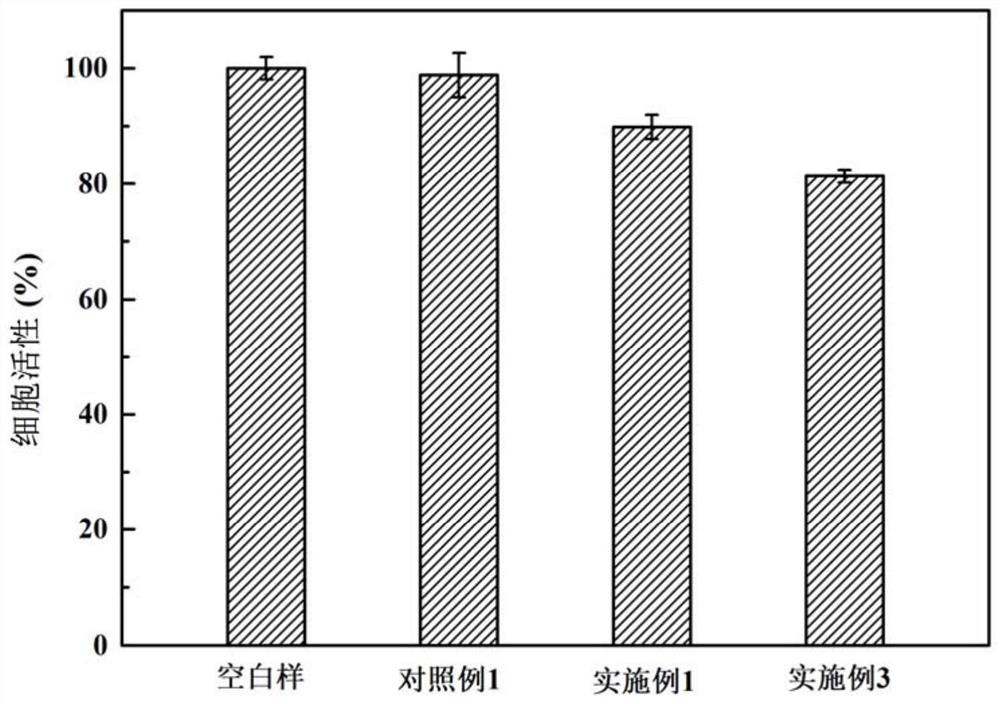

A bacterial cellulose and temperature-responsive technology, which is applied in the direction of antibacterial drugs, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. Inconvenience and other problems, to achieve good biocompatibility and temperature-sensitive reactivity, to achieve long-term release, high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

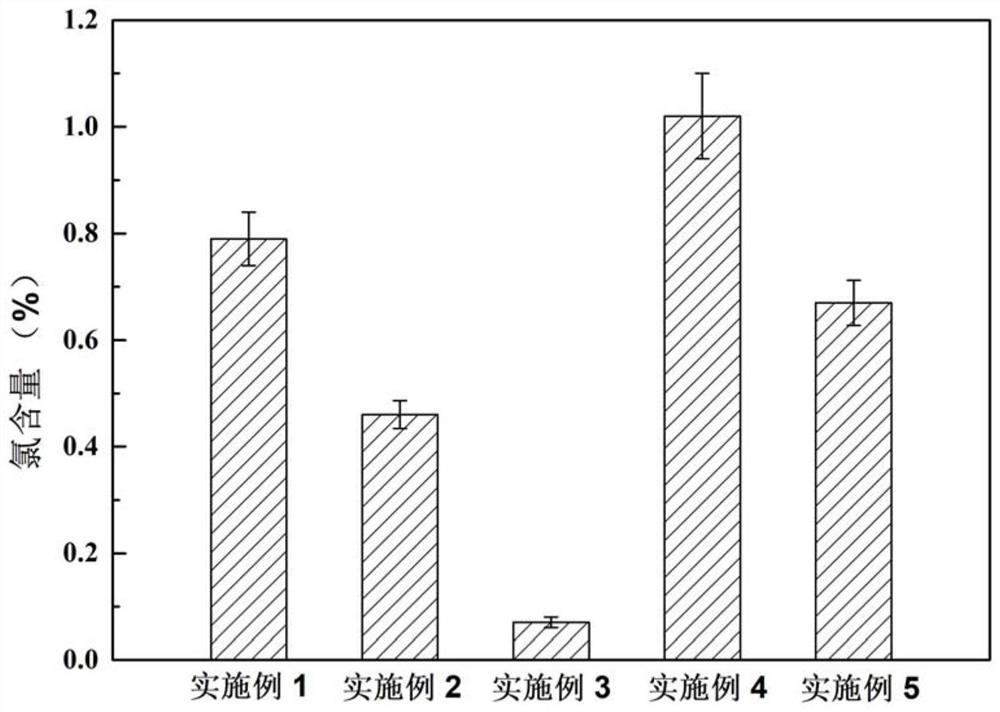

Embodiment 1

[0050] A method for preparing a temperature-responsive bacterial cellulose antibacterial nanogel, comprising the steps of:

[0051] (1) The preparation method of bacterial cellulose nano whisker suspension:

[0052] Take the bacterial cellulose suspension with a solid content of 2.11% and freeze-dry (-60°C for 24h) to obtain bacterial cellulose; then add 1g of bacterial cellulose to 100mL 70% sulfuric acid solution and stir at 60°C for 12 hours, and the solution after stirring Dialyze with water (molecular cut-off value 8000u, dialysis for 3 days), after dialysis, freeze-dry (freeze at -60°C for 24h) to obtain bacterial cellulose nano-whisker powder; weigh bacterial cellulose nano-whisker powder and disperse it in water and stir Uniformly prepare bacterial cellulose nano-whisker suspensions with a solid content of 0.75% bacterial cellulose nano-whiskers;

[0053] (2) Tris (hydroxymethyl) aminomethane buffer solution is added in the bacterial cellulose nano whisker suspension ...

Embodiment 2

[0057] A method for preparing a temperature-responsive bacterial cellulose antibacterial nanogel, comprising the steps of:

[0058] (1) The preparation method of bacterial cellulose nano whisker suspension is:

[0059] The bacterial cellulose suspension with a solid content of 2.11% was freeze-dried (-60°C for 24h) to obtain bacterial cellulose; 1g of bacterial cellulose was added to 100mL of 50% sulfuric acid solution and stirred at 60°C for 12 hours. After stirring, the solution was Water dialysis (molecular cut-off value 8000u, dialysis for 3 days), after dialysis, freeze-dry at -60°C for 24 hours to obtain bacterial cellulose nano-whisker powder; weigh bacterial cellulose nano-whisker powder and disperse in water and stir evenly to obtain bacterial fiber Suspension of bacterial cellulose nano-whiskers with a solid content of 0.5%.

[0060] (2) Tris (hydroxymethyl) aminomethane buffer solution is added in the bacterial cellulose nano whisker suspension in 10mL step (1), wh...

Embodiment 3

[0064] A method for preparing a temperature-responsive bacterial cellulose antibacterial nanogel, comprising the steps of:

[0065] (1) The preparation method of bacterial cellulose nano whisker suspension is:

[0066] The bacterial cellulose suspension with a solid content of 2.11% was freeze-dried (-60°C for 24h) to obtain bacterial cellulose; 1g of bacterial cellulose was added to 100mL of 50% sulfuric acid solution and stirred at 60°C for 6 hours. After stirring, the solution was Water dialysis (molecular cut-off value 8000u, dialysis for 3 days), after dialysis, freeze-dry at -60°C for 24 hours to obtain bacterial cellulose nano-whisker powder; weigh bacterial cellulose nano-whisker powder and disperse in water and stir evenly to obtain bacterial fiber Suspension of bacterial cellulose nano-whiskers with a solid content of 0.2%.

[0067] (2) Tris (hydroxymethyl) aminomethane buffer solution is added in the bacterial cellulose nano whisker suspension in 10mL step (1), whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com