Uniform batching equipment for enzyme preparation production

A technology for batching equipment and enzyme preparations, which is applied to mixer accessories, dissolving, mixers, etc., can solve the problems of low discharge efficiency, time-consuming and laborious cleaning of inner walls, and easy adhesion of enzyme preparations to the inner wall of the batching cylinder, so as to prevent clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

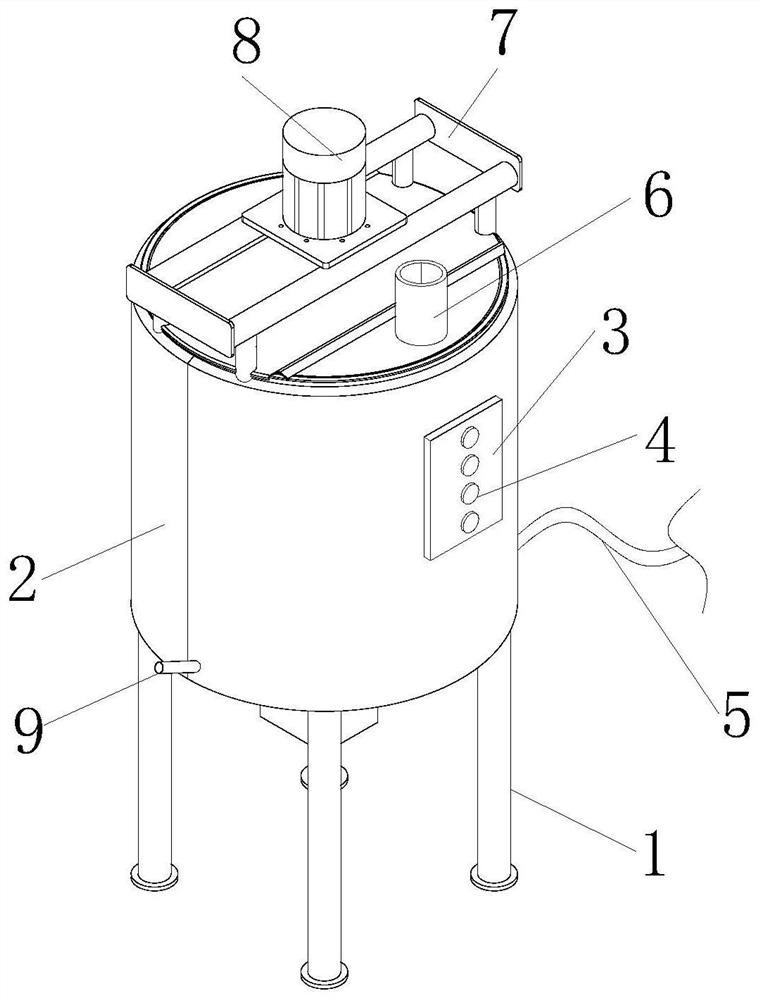

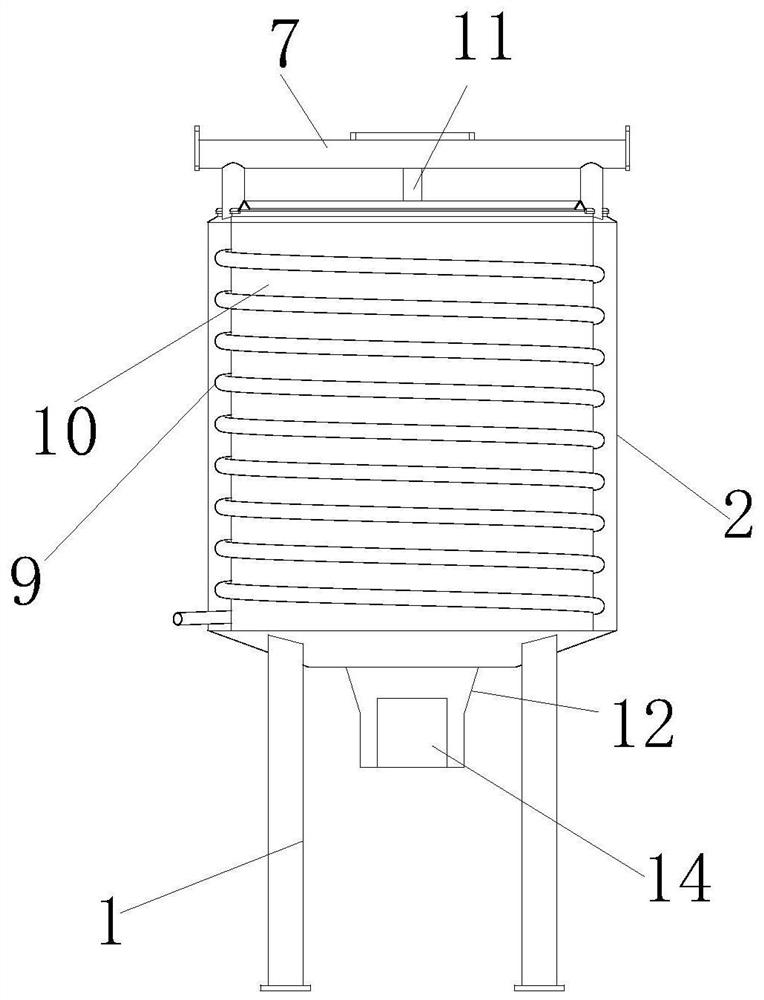

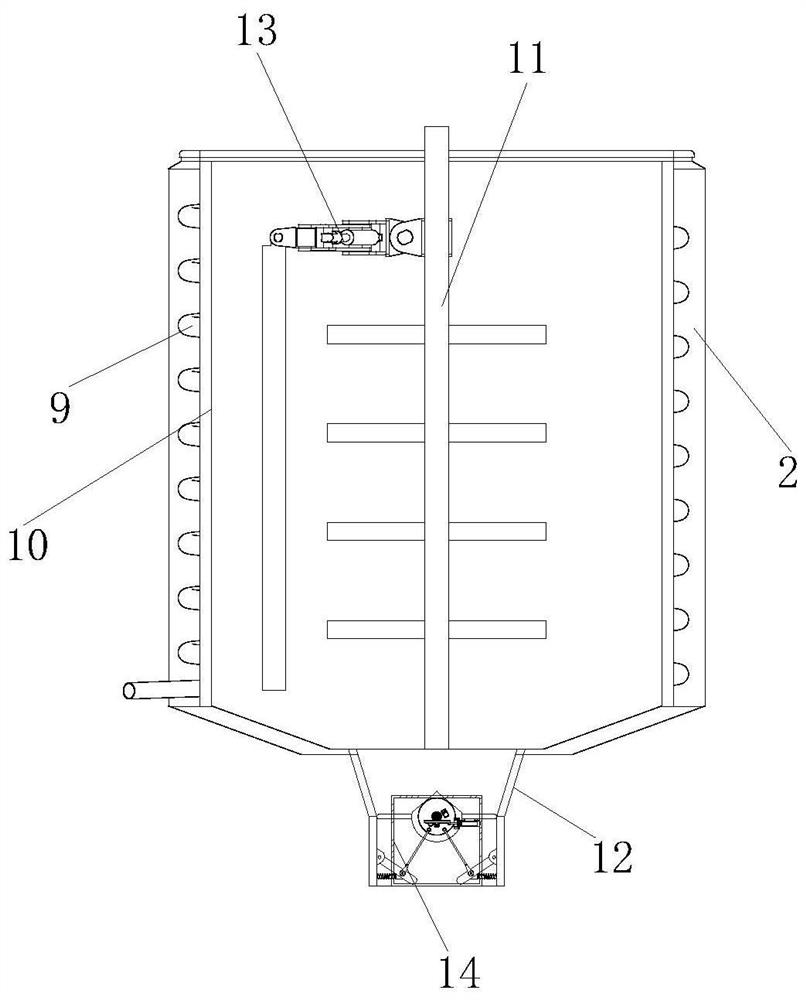

[0035] see figure 1 , figure 2 and image 3, the present invention provides a uniform batching equipment for enzyme preparation production through improvement, including support feet 1, heat preservation frame 2, feed pipe 6, support frame 7, batching frame 10, stirring shaft 11, discharge pipe 12, swing Cleaning mechanism 13 and material distributing and discharging mechanism 14, supporting legs 1 and the bottom four corners of heat preservation frame 2 are welded and fixed, the right end of heat preservation frame 2 is provided with control panel 3, the front end of control panel 3 is equipped with button 4, and swing cleaning mechanism 13 is installed and fixed on the stirring shaft 11 upper end, material distributing and discharging mechanism 14 is arranged inside the discharge pipe 12, and the rear end of the heat preservation frame 2 is fixed with a power lead 5, and the inside of the heat preservation frame 2 is provided with a batching frame 10, and the batching fram...

Embodiment 2

[0042] The present invention provides a kind of uniform batching equipment for the production of enzyme preparation through improvement, the first cylinder 133 and the second cylinder 139 have the same size, and the upper ends of the first cylinder 133 and the second cylinder 139 are all provided with a fixed seat 134, which is beneficial to play To drive the scraper 138 to tilt, there are three connecting blocks 137, and the connecting blocks 137 are equidistantly distributed along the left end of the horizontal plate 135, which is beneficial to stably fix the scraper 138.

[0043] The invention provides a uniform batching equipment for enzyme preparation production through improvement, and its working principle is as follows;

[0044] First, before use, place the uniform batching equipment for enzyme preparation production horizontally, so that the supporting feet 1 can fix the equipment;

[0045] Second, when in use, connect the external power supply through the power lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com