Ultrasonic washing equipment for high-nickel ternary lithium battery positive electrode powder material

A ternary lithium battery and powder material technology, which is applied in the directions of cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids, etc., can solve problems such as the decrease in the safety of battery cells, and achieve low power consumption and water washing effect. Good, easy to operate and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which do not limit the scope of protection claimed by the present invention.

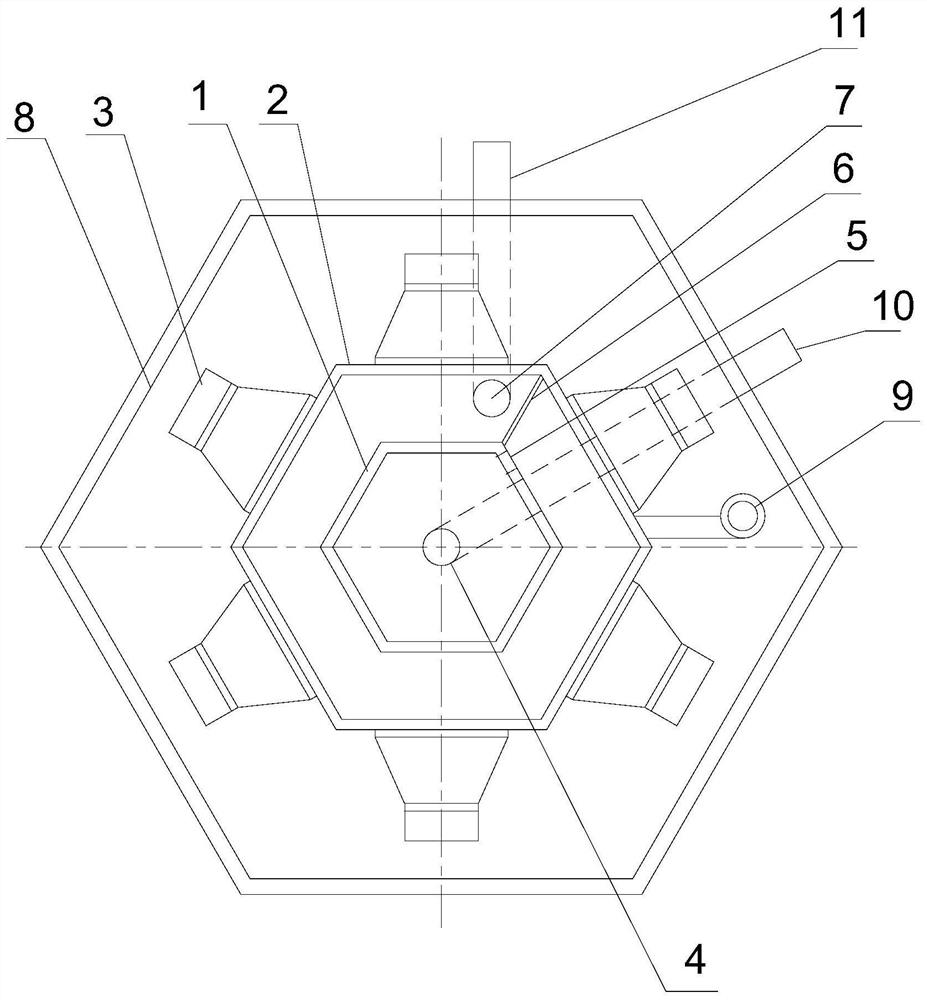

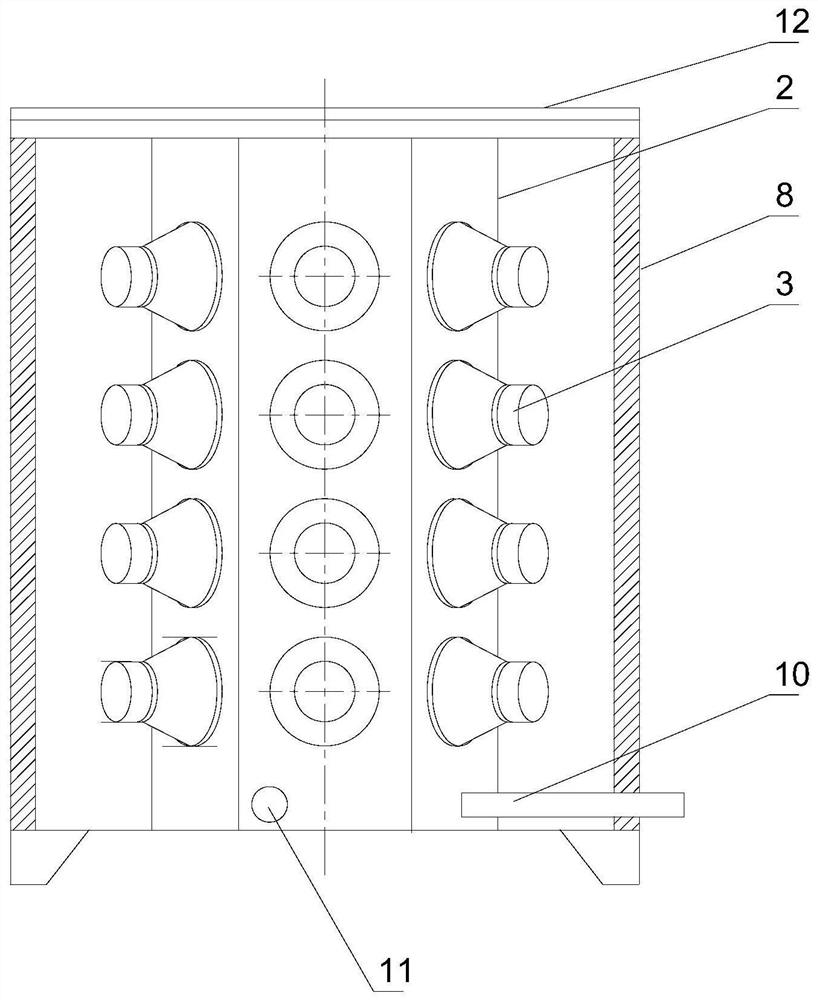

[0018] See figure 1 with figure 2 , a high-nickel ternary lithium battery positive electrode powder material ultrasonic washing equipment, including a cleaning tank, the cleaning tank includes a tank wall 8 and a tank bottom. The cleaning tank is sequentially provided with an inner partition 1 and an outer partition 2 along the axial direction of the cleaning tank at intervals from the inside to the outside. The inner partition 1 and the outer partition 2 are both cylindrical and the inner partition 1 and the outer partition 2 The bottom ends are all airtightly connected with the inner surface of the tank bottom. The top of the inner partition 1 is provided with an overflow port 5. The inner partition 1 and the bottom of the tank together form an inner cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com