Auxiliary device for butt welding of steel bars for building construction

A technology for building construction and auxiliary equipment, applied in auxiliary equipment, welding/cutting auxiliary equipment, auxiliary welding equipment, etc. Improved functionality and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

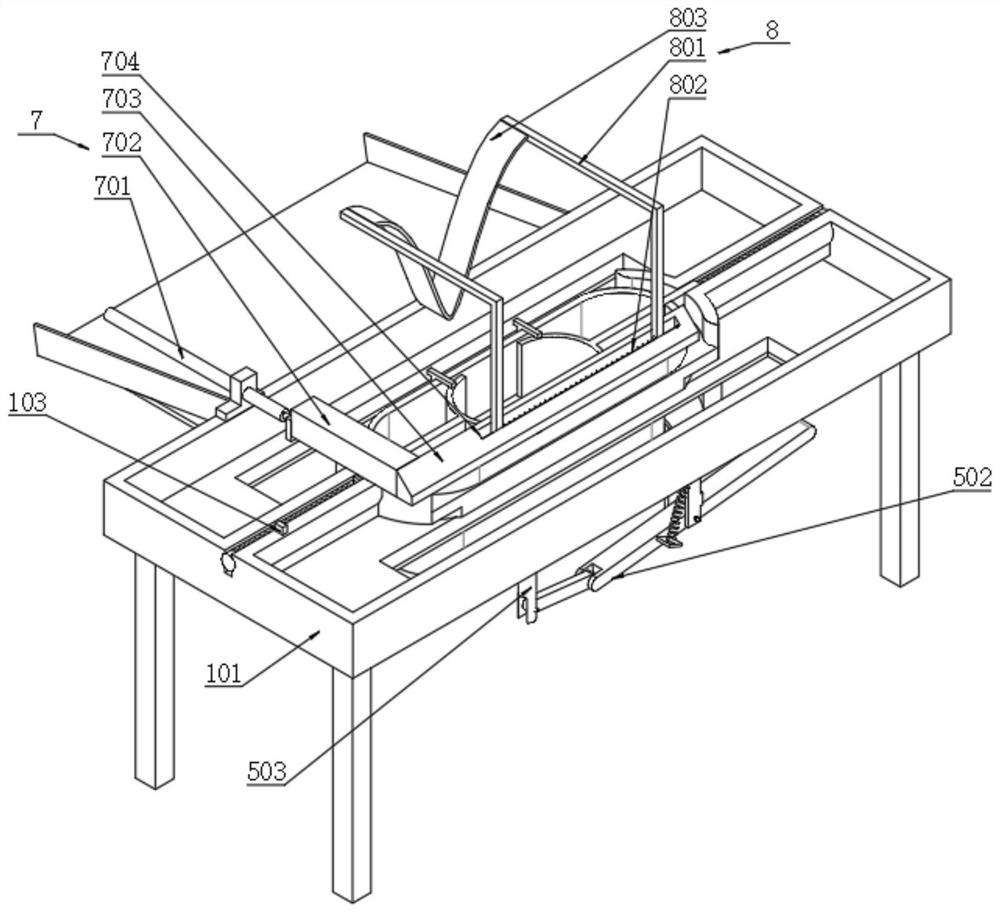

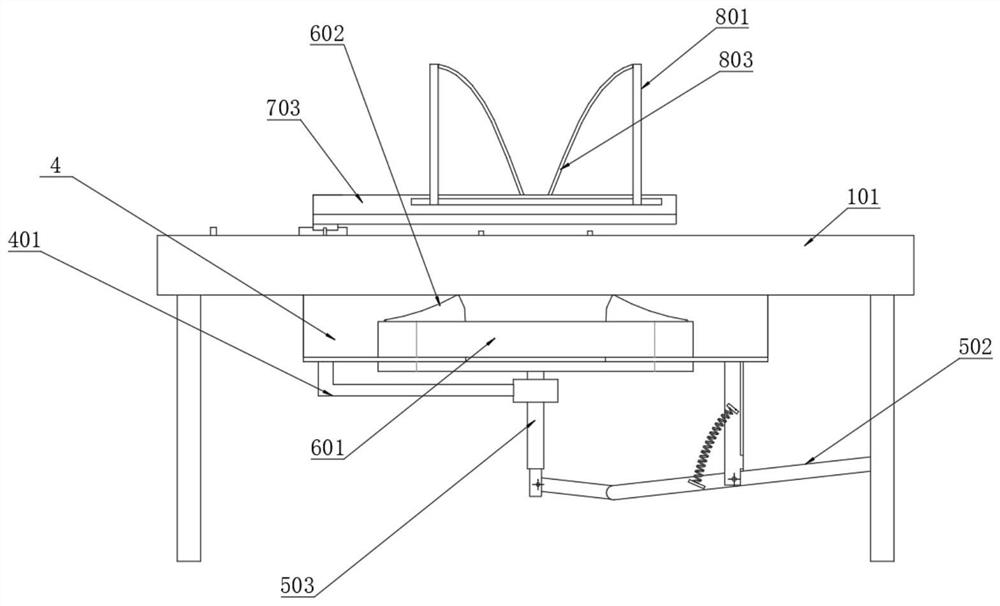

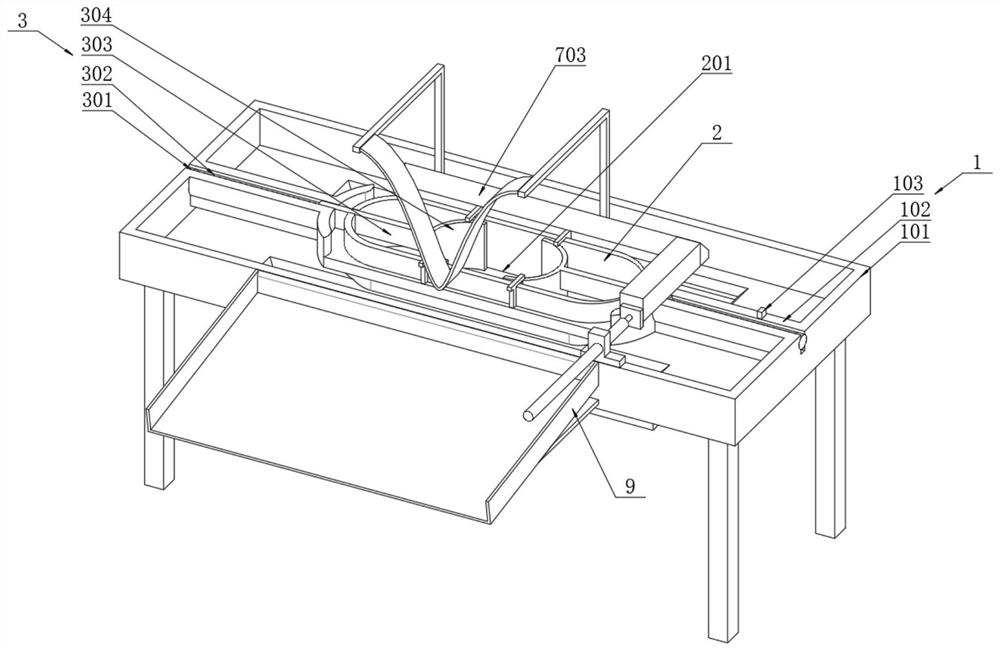

[0032] The following is attached figure 1 - Figure 10 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0033] The auxiliary device for butt welding of steel bars for building construction includes a pedestal mechanism 1, a clamping cabin 2, a clamping mechanism 3, a connecting rod mechanism 5, a material return mechanism 6, a material pulling mechanism 7 and an anti-fall mechanism 8; the middle part of the pedestal mechanism 1 is provided with The clamping cabin 2 is provided with a clamping mechanism 3 inside the clamping cabin 2. When the clamping mechanism 3 moves inward, the steel bars inserted in the clamping cabin 2 are clamped, and the bottom surface of the pedestal mechanism 1 is welded with a hanging plate 4. The hanging plate 4 is provided with a material return mechanism 6, and the bottom of the pedestal mechanism 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com