Automatic removing device for concrete on surface of steel pipe

An automatic removal and concrete technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of difficult cleaning of steel pipes, high noise, and much dust, so as to achieve convenient removal, improve convenience, increase The effect of fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

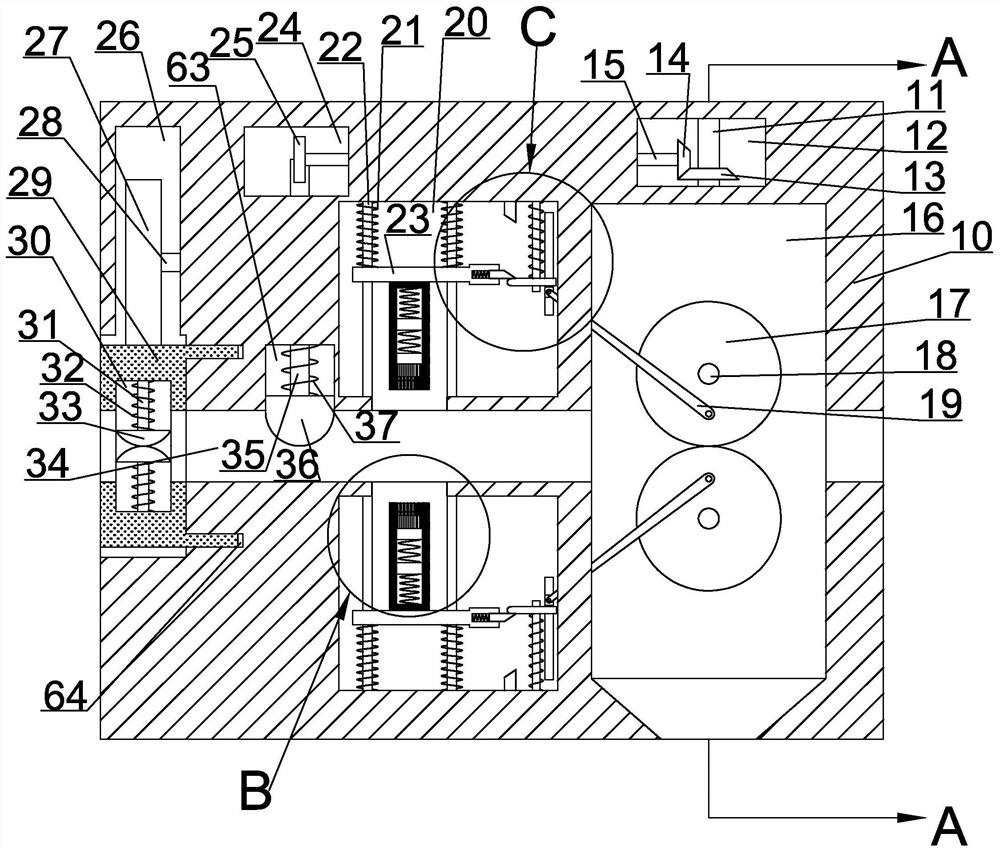

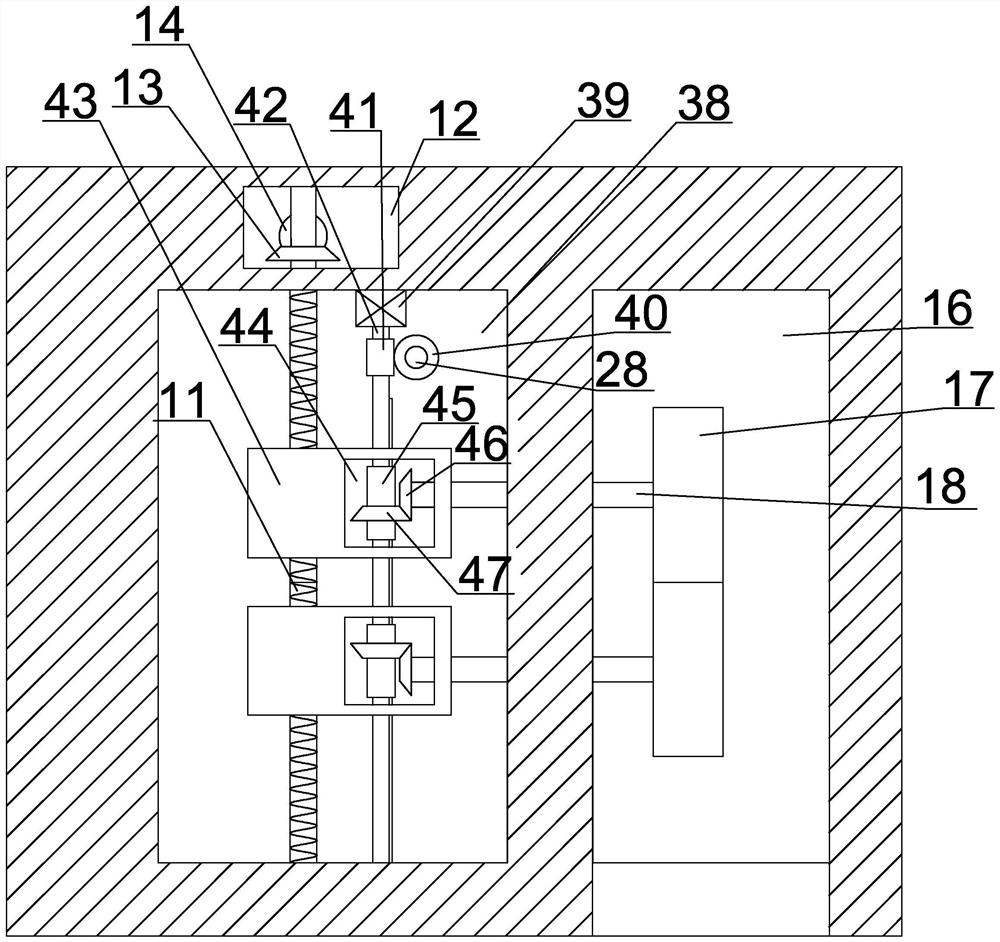

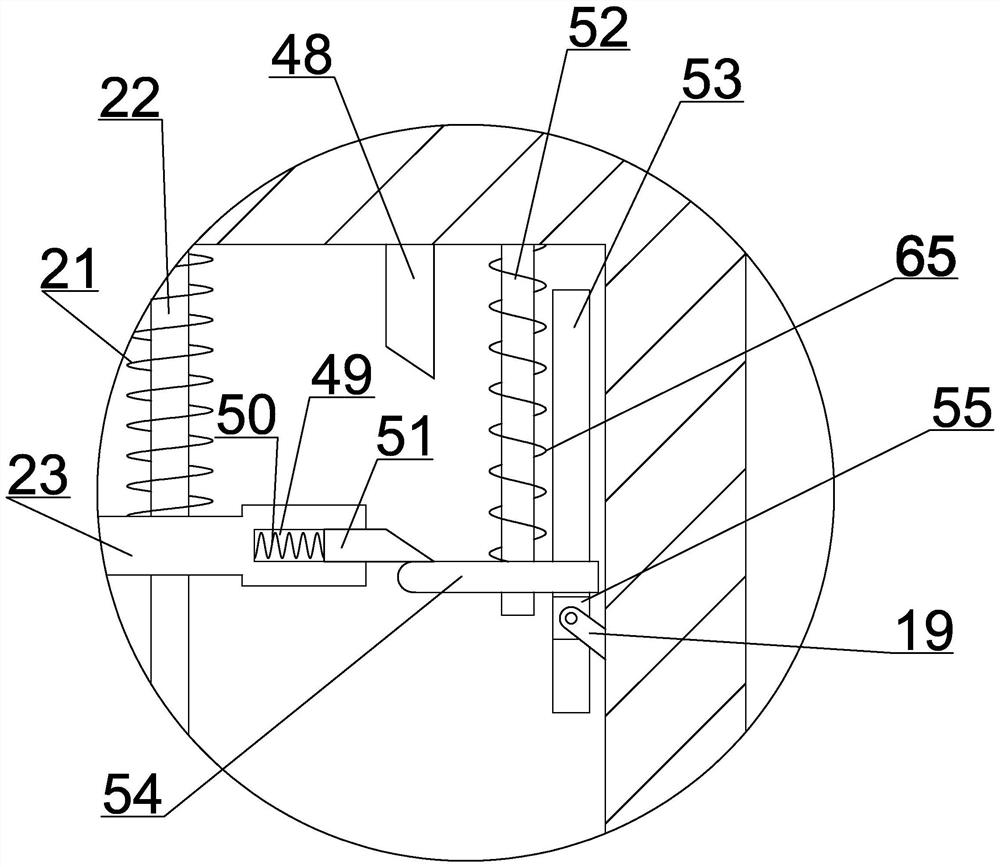

[0024] like figure 1 As shown, a device for automatic removal of concrete on the surface of steel pipes, including a body 10, is characterized in that: the body 10 defines a third space 26 with an opening to the left, and the third space 26 is provided with a steel pipe for rotating The rotating mechanism, the right side wall of the third space 26 communicates with a circular chute 64, the right side of the third space 26 defines a steel pipe passage 34, and the steel pipe passage 34 communicates with the third space 26, The upper and lower sides of the steel pipe channel 34 are respectively defined with pinching spaces 20, and the two pinching spaces 20 are symmetrically distributed up and down with respect to the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com