Dish passing robot suitable for overhead track

A technology of robots and robot machines, which is applied in the field of vegetable transfer robots, can solve the problems of low efficiency, poor stability, and easy shaking during food transfer, and achieve the effects of convenient and flexible layout, eliminating shaking, and avoiding lateral inertial forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

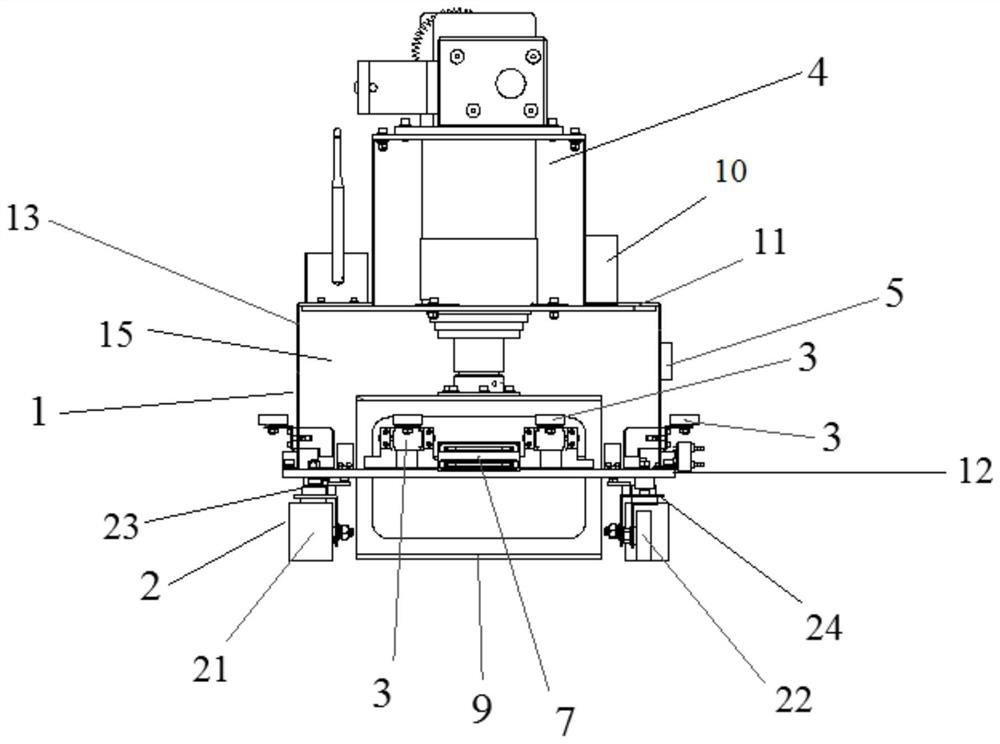

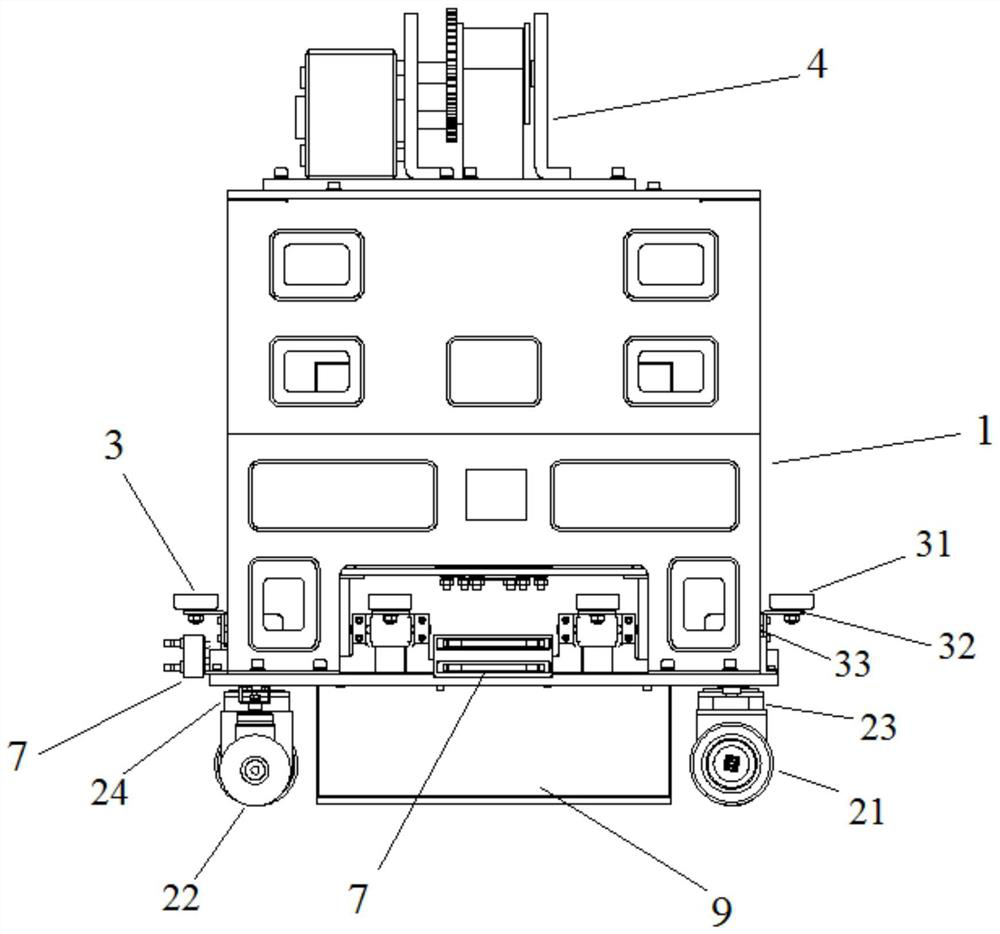

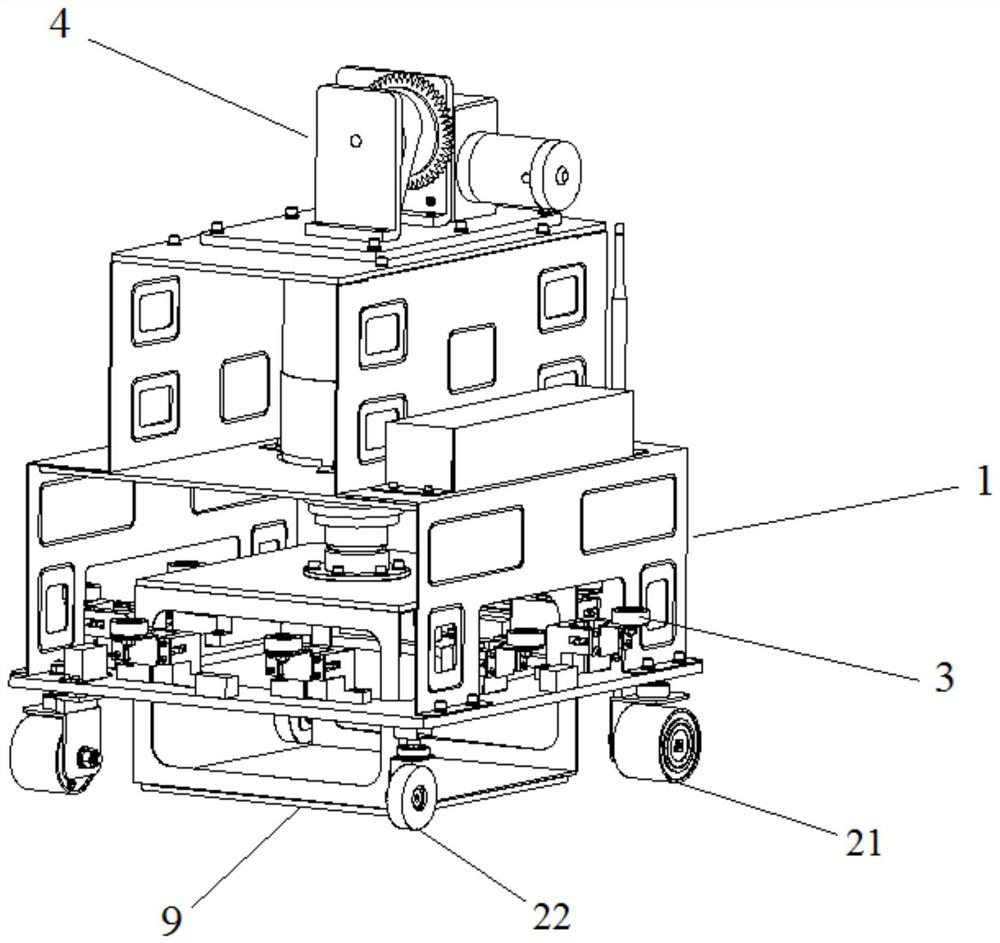

[0059] This embodiment proposes a kind of robot that is suitable for passing food on overhead track, and its structure sees figure 1 and figure 2 As shown, it includes a robot frame 1, a driving wheel assembly 2 arranged at the bottom of the robot frame 1, and a guide wheel assembly 3 installed on the side of the robot frame 1. The robot frame 1 has a hollow cavity 15 with a bottom opening 14 , a lifting mechanism 4 is also installed on the top of the robot frame 1. The movable end of the lifting mechanism 4 stretches into the hollow cavity 15 and is fixedly connected with a vegetable delivery box. 4 drives up and enters the hollow cavity 15 along the bottom opening 14 until all or part of it is hidden in the hollow cavity 15. When the lifting mechanism 4 descends, the vegetable transfer box is driven by the lifting mechanism 4 to drop and leave the hollow cavity 15 until Serving position located above the dining table area.

[0060] see you again Figure 1-Figure 4 etc.,...

Embodiment 2

[0067] On the basis of Embodiment 1, this embodiment further adopts the following settings:

[0068] The side of the robot frame 1 is also provided with a current collector 7 that is in contact with the trolley line arranged on the overhead track 6, see Figure 7 and Figure 8 As shown, the current collector 7 includes a collector base 701, a movable slider 702, a carbon brush holder 703, a carbon brush head 704, a first buffer elastic member 705, a connecting rod 706 and a first drive member 707, wherein, The movable slider 702 is slidably arranged on the collector base 701, and has a degree of freedom along the direction of approaching or moving away from the trolley line. The degree of freedom of the line, the carbon brush head 704 is fixedly installed on the carbon brush holder 703, and is connected to the power-taking structure arranged on the robot frame 1 through the lead wire 713, and the first buffer elastic member 705 is arranged between the carbon brush holder 703 ...

Embodiment 3

[0075] On the basis of embodiment 1 or embodiment 2, this embodiment further adopts the following settings:

[0076] See Figure 9-Figure 11 As shown, a brake device 8 is also provided on the robot frame 1, and the brake device 8 includes a brake support frame 801, two brake connecting pieces 802, a brake pad 803, a tensile elastic member 804, a cam 805 and a brake driver 806 , the middle position of the brake connecting piece 802 is rotatably installed on the brake support frame 801, and the line connecting the rotation connection points of the two brake connection pieces 802 and the brake support frame 801 is the dividing line, and the brake connecting piece 802 is at the boundary of the dividing line. One end is equipped with a brake pad 803, and the other end of the two brake connecting pieces 802 is connected by a tensile elastic member 804 at the other end of the dividing line. At the same end, the output end of the brake driver 806 is fixedly connected to the cam 805, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com