A lithium battery recycling and cutting device

A cutting device, lithium battery technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of increasing the difficulty of material sorting, the difficulty of recycling the insulating coating, etc., to reduce the sorting Difficulty, convenient collection, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

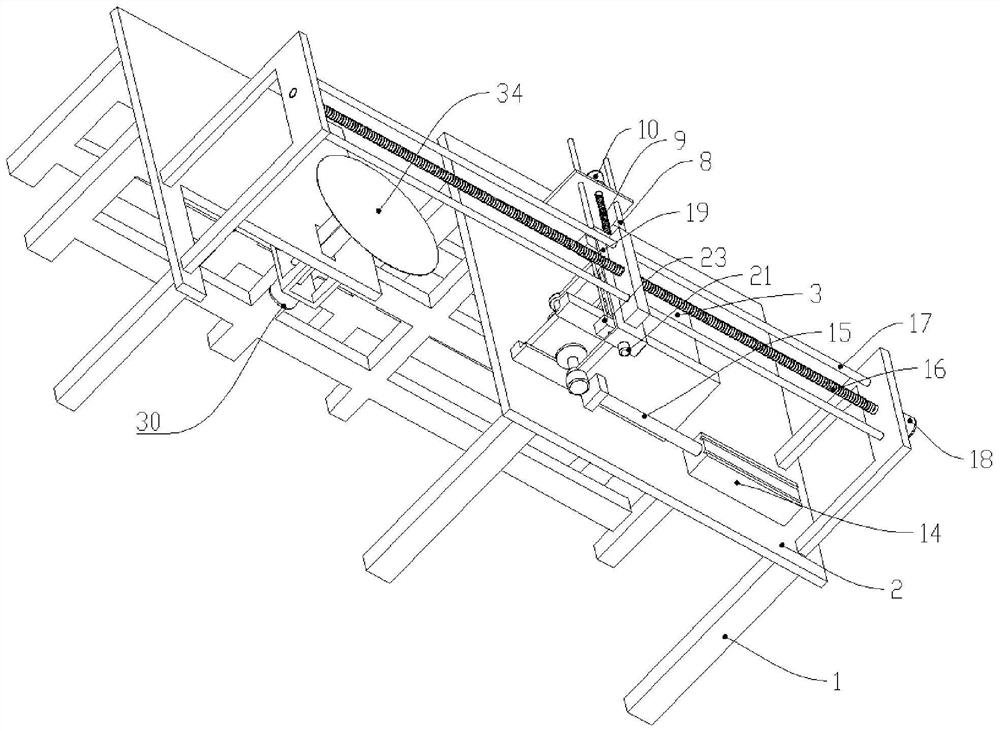

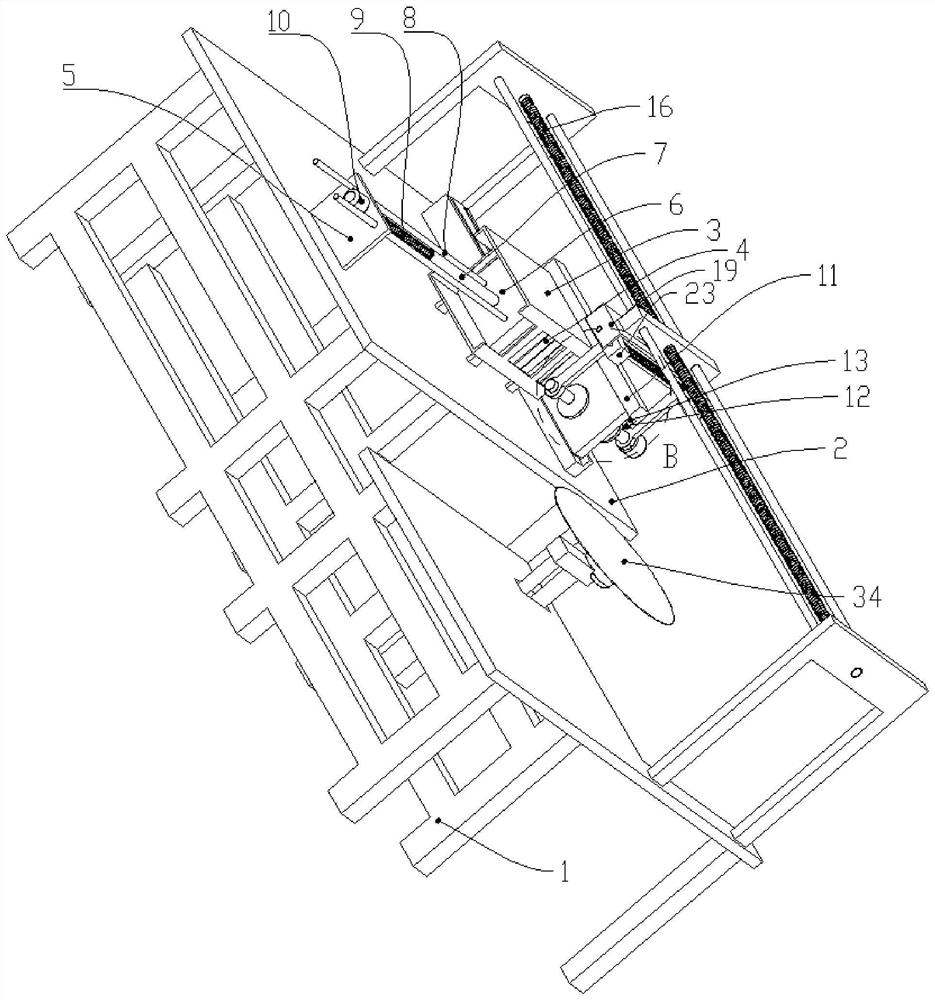

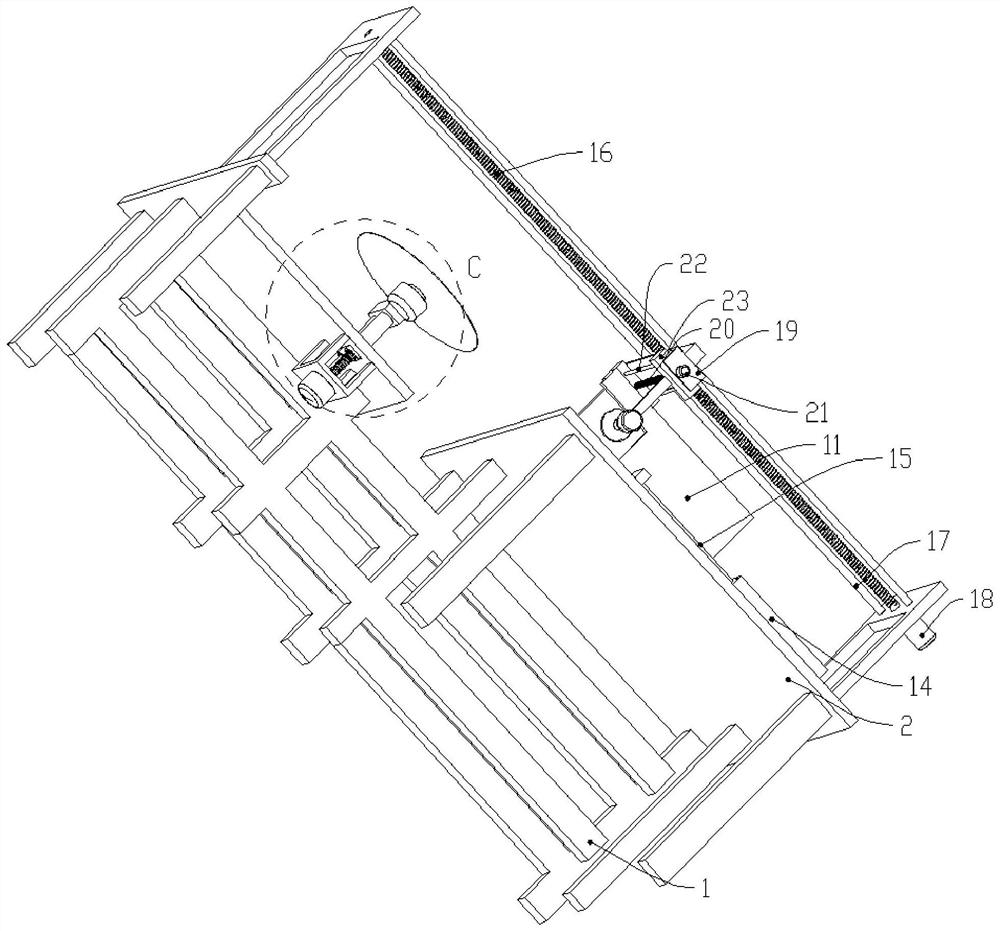

[0024] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

[0025] Such as Figure 1 to Figure 7As shown, the present invention discloses a lithium battery recycling and cutting device, including a frame 1, a table top 2 is fixed on the frame 1, a bracket 3 is fixed on the table top 2, and a battery 4 to be disassembled is evenly fixed on the bracket 3, and the bracket 3 A pushing device is fixed on one side, and the pushing device includes a push plate 6 arranged inside the bracket 3 and slidingly connected with the bracket 3. The threaded pipe I7 and a plurality of support rods 8 are fixed horizontally on the push plate 6, and the pushing device also includes a push plate fixed on the table. 2 on the support plate 5, the support rod 8 passes through the support plate 5 and is slidably connected with the support plate 5, and the support plate 5 is also fixed with a screw rod I9, which is driven by the motor I10 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com