Process and system for domestic garbage incineration waste heat drying pretreatment

A technology for domestic waste incineration and urban domestic waste, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as large energy consumption, and achieve the effects of improving recovery efficiency, increasing low calorific value, and improving incineration processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

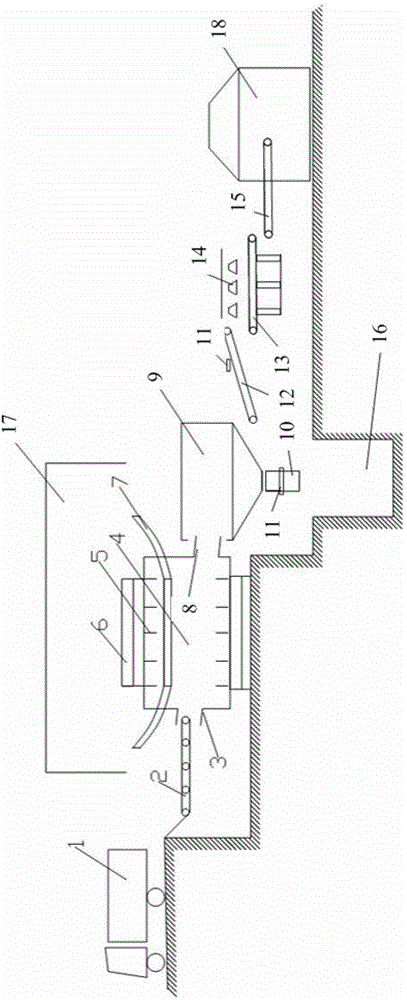

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0045] The present invention provides a pretreatment process for waste heat drying of domestic waste incineration, comprising the following steps:

[0046] S1. Unloading: The collected municipal solid waste is unloaded in the unloading hall, and transported to the drying equipment through the apron feeder.

[0047] S2. Drying: Urban domestic waste is stirred continuously for 20-30 minutes at a temperature of 180-200°C, causing the plastic bag or packaging to break, the water in the waste is evaporated, and its moisture content is reduced to 15%;

[0048] Specifically, the heat source of the garbage drying drum is firstly the waste heat steam from waste incineration power generation, which wraps the outside of the drying drum; Under the adjustment of the control system, the two systems realize the stability of the moisture content of the garba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com