Novel rubber cutting machine for rubber preparation

A rubber cutting machine and rubber technology, applied in the field of rubber, can solve the problems of laborious replacement, only complete replacement, and high cost, and achieve the effects of ensuring cutting quality, speeding up cutting, and increasing flexibility in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

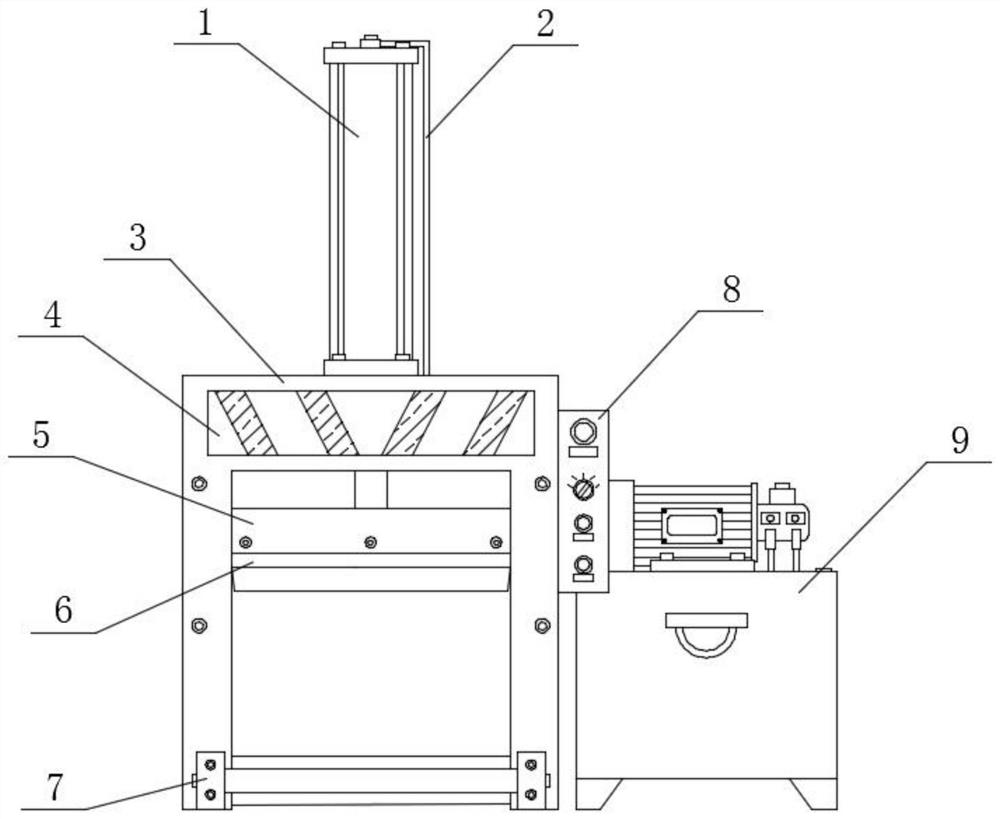

[0031] Such as Figure 1-4 As shown, a new type of rubber cutting machine for rubber preparation includes a cutting table 3 and a hydraulic cylinder 1. The top end of the cutting table 3 is connected with a hydraulic cylinder 1. The hydraulic cylinder 1 can be connected with the hydraulic oil pump 9 through the oil pipe 2. The bottom end face of the oil cylinder 1 is connected with a telescopic rod inside the front end face of the cutting table 3, and the oil pipe 2 is connected to the right side of the top end face of the hydraulic cylinder 1. The inner surface of the oil pipe 2 is hollow, and the telescopic rod can drive the fixed frame 5 Carry out up and down movement to realize the cutting function. The lower part of the oil pipe 2 is provided with a reflective sticker 4 at the position above the front end of the cutting table 3. The reflective sticker 4 is reflective and arranged symmetrically. The lower part of the reflective sticker 4 is located on the cutting table. Th...

Embodiment 2

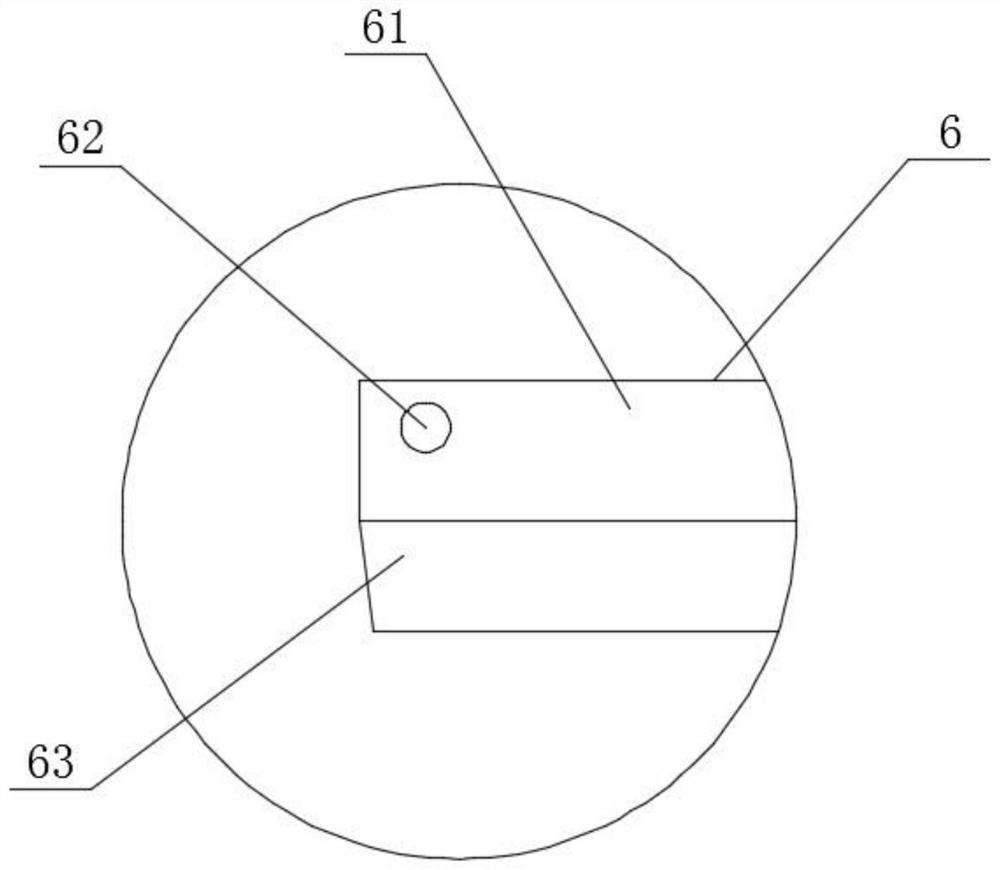

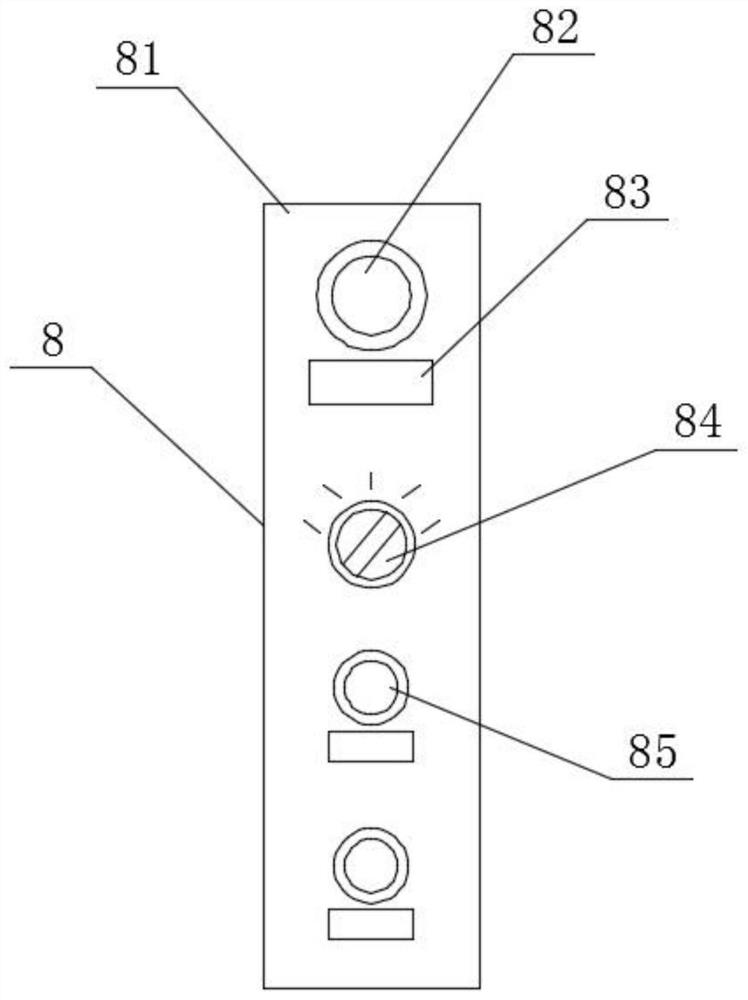

[0035] Such as Figure 1-7 As shown, a new rubber cutting machine for rubber preparation includes a cutting table 3 and a hydraulic cylinder 1. The top end surface of the cutting table 3 is connected to the hydraulic cylinder 1, and the right side of the top end surface of the hydraulic cylinder 1 is connected to the oil pipe 2. The oil pipe 2 The lower part is provided with a reflective sticker 4 at the upper position of the front end face of the cutting table 3, and the lower part of the reflective sticker 4 is provided with a fixing frame 5 inside the front end face of the cutting table 3, and the bottom end face of the fixing frame 5 is connected by bolts. The blade 6 is disassembled, and a roller table 7 is arranged below the front end face of the cutting table 3 under the dismantling blade 6, and an operation panel 8 is arranged above the roller table 7 above the right end face of the cutting table 3 , the rear of the operation panel 8 is provided with a hydraulic oil pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com