An inner bag grabbing mechanism for double-layer ton bags

A technology of grabbing mechanism and big bag, which is applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc. It can solve the problems of inconvenient arrangement of inflatable tubes, easy loose inner bags, easy to tear inner bags, etc. Achieve the effects of avoiding air leakage, improving work efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

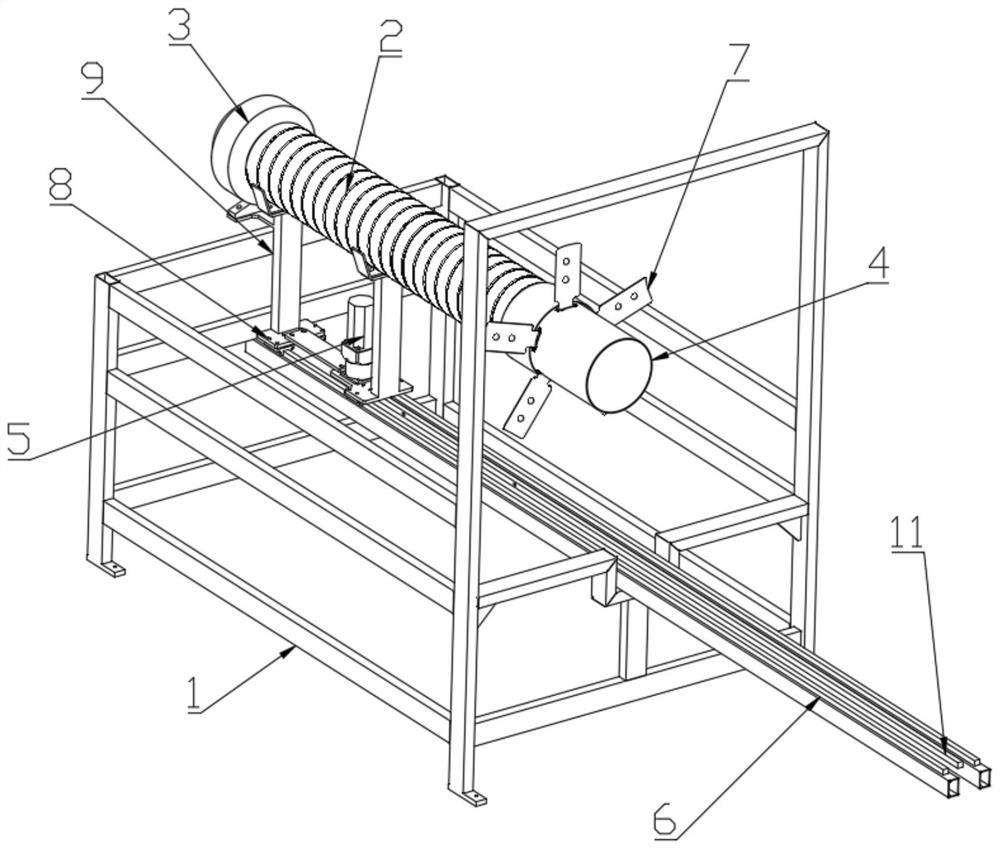

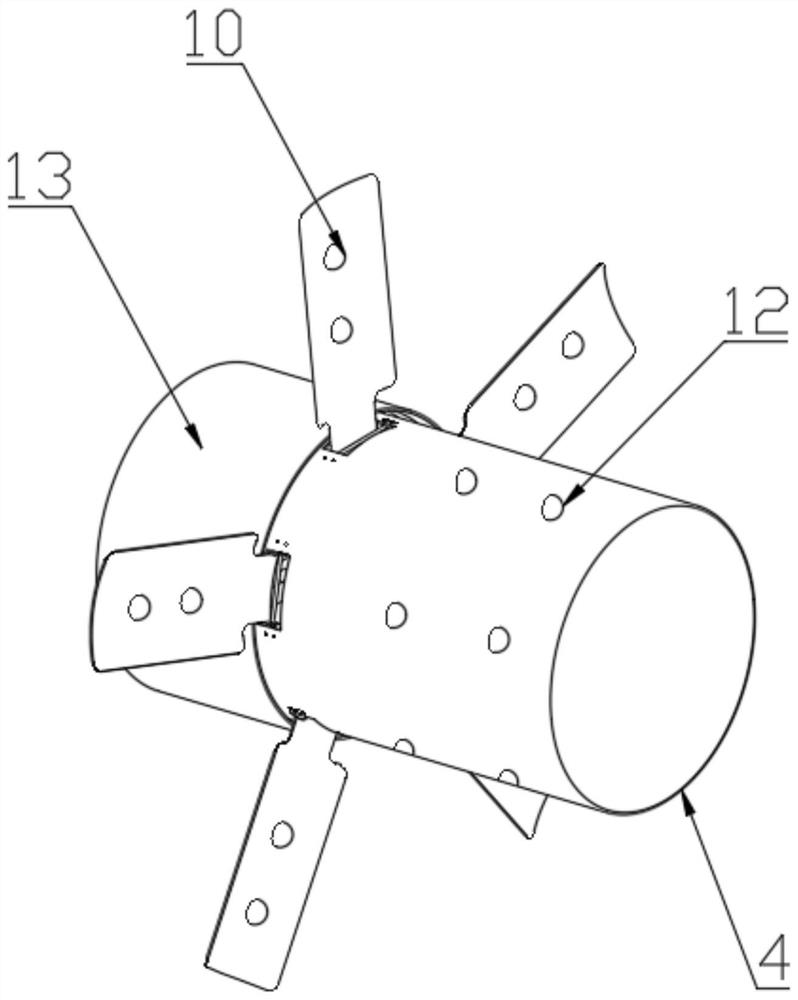

[0030] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

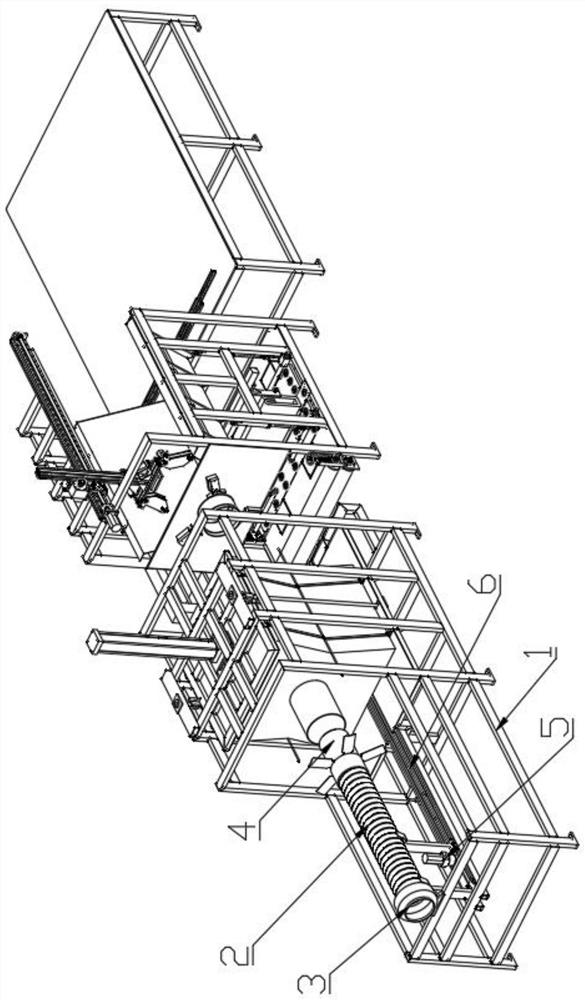

[0031] like figure 1 , 2 As shown, an inner bag grabbing mechanism for a double-layer ton bag, including

[0032] Frame 1, the frame 1 is installed at the front of the big bag support mechanism, including a plurality of assembled profiles,

[0033] The air supply pipe 2 is fixedly connected to the bracket 9 of the base 8. An axial flow fan 3 is installed at one end of the air supply pipe 2, and a sleeve 13 is installed at the other end. The sleeve 13 is cylindrical and has the same diameter as the air supply pipe 2 ,

[0034] The axial flow fan 3 is installed at the rear end of the air supply pipe 2, moves along with the air supply pipe 2, and is connected to a power supply to provide wind pressure.

[0035] Horizontal movement assembly, mass drive motor, guide rail 6, rack 11, base 8, two guide rails 6 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com