Self-closing liquid packaging container and method for controlling liquid discharging of container

A packaging container and self-closing technology, which is applied in the field of self-closing liquid packaging containers and controlling container liquid discharge, can solve the problems of non-reflux, deterioration, and dryness of liquid, and achieve the effect of preventing liquid from flowing out of the container and buffering the flow of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]This embodiment provides a self-closing liquid packaging container. The material of the container can be any suitable material, and the liquid contained in the container can be any type of liquid (not conflicting with the container material), especially suitable for those with a certain viscosity Liquids, such as liquid detergents, personal care products or liquid flavoring agents;

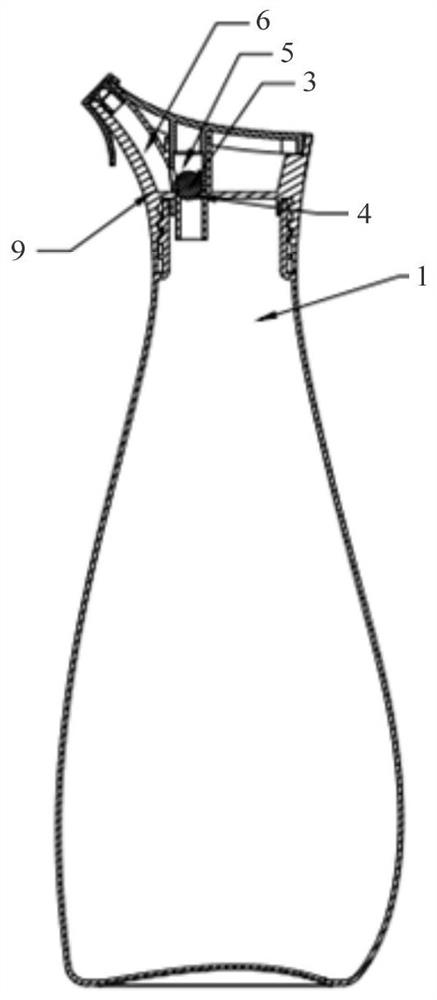

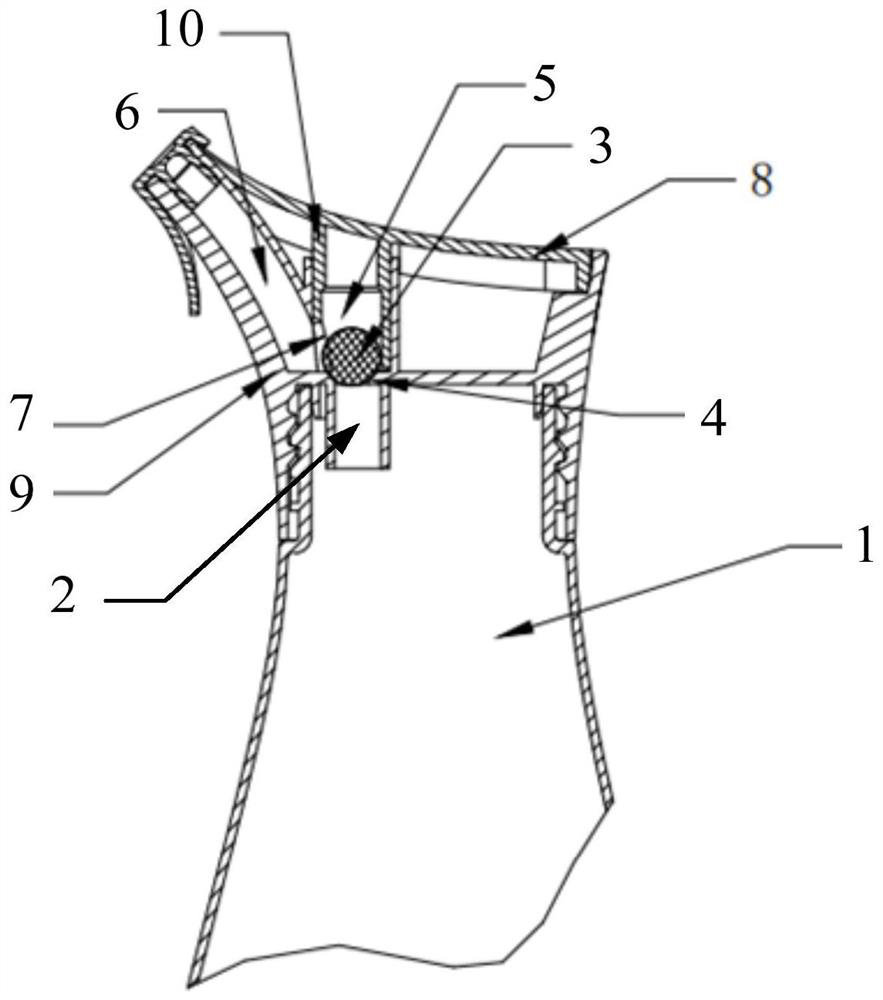

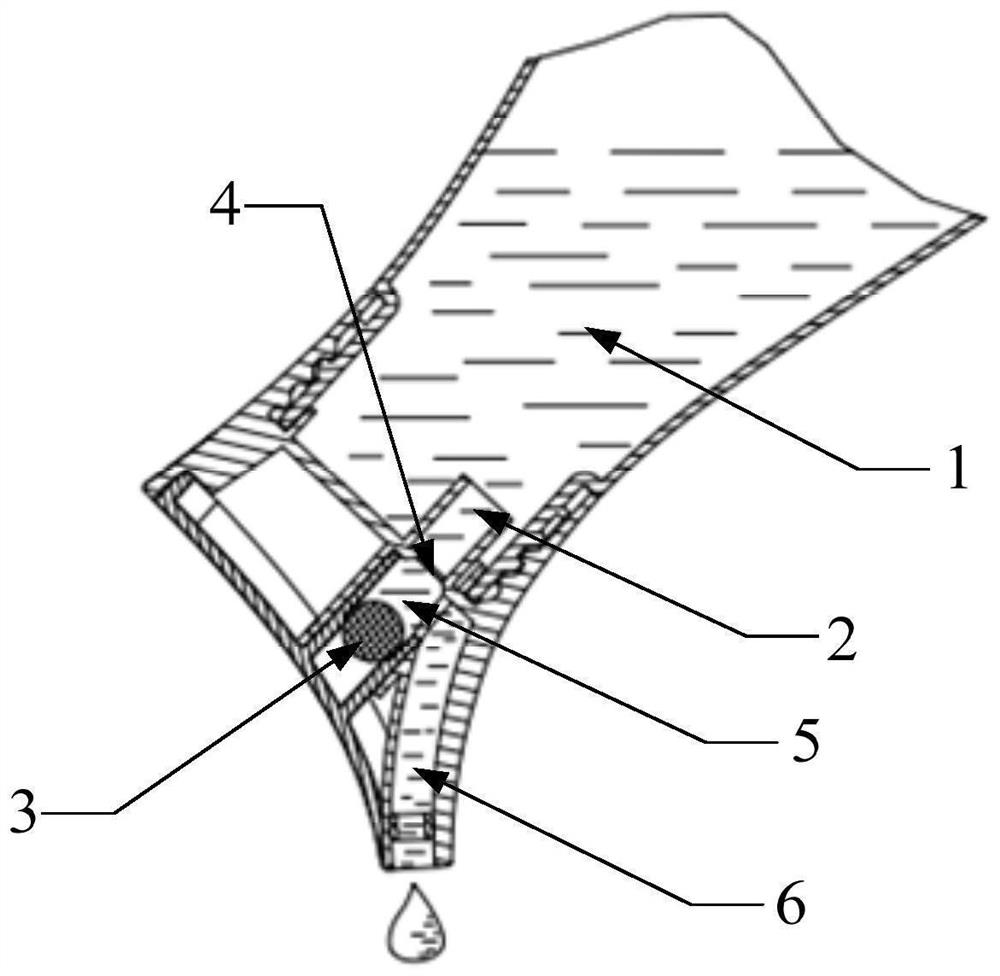

[0041]Such asfigure 1 As shown, the container includes a container cavity 1, such asfigure 2 As shown, the container includes a liquid outlet 2, a ball valve 3, a valve seat 4, a ball valve movable channel 5, and a liquid outflow channel 6 communicating with the container cavity 1.

[0042]The valve seat 4 is set at the liquid outlet 2 and does not affect the connectivity of the liquid outlet 2, and is used to support the ball valve 3 when the container is being placed. When the ball valve 3 is limited to the valve seat 4, the lower part of the ball valve 3 The surface is attached to the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com