Automatic air sweeping device of cloth paving machine

A cloth spreading machine and air sweeping technology, which is applied in transportation and packaging, spreading thin soft materials, thin material processing, etc., can solve the problem of difficulty in laying cloth neatly, low production efficiency, skewed and misaligned ends of cloth spreading, etc. problem, to achieve the effect of high automation control, quality improvement and wrinkle resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

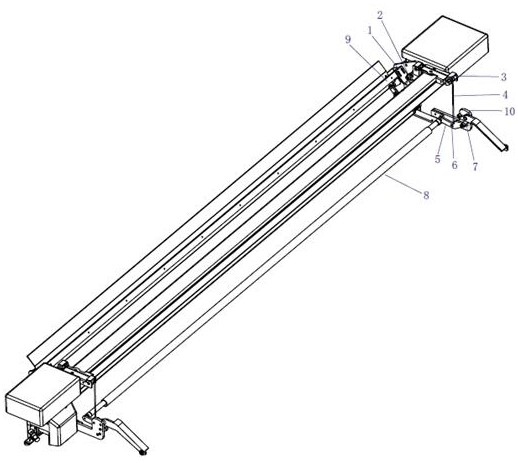

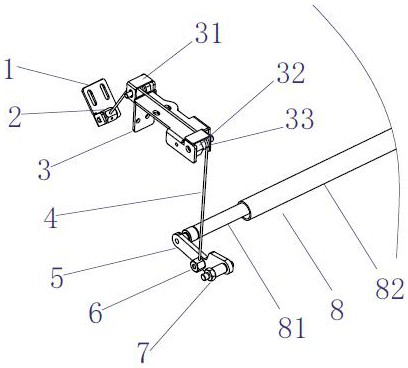

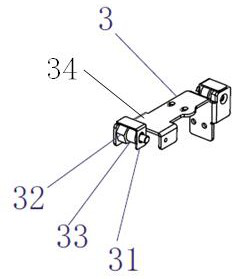

[0028] Figure 1 to Figure 3 A schematic structural diagram of an embodiment of the present invention is shown. Such as Figure 1-Figure 3 As shown, the present invention provides an automatic air sweeping device for a cloth spreading machine, and the automatic wind sweeping device is mounted on the front end of the cutter assembly of the cloth spreading machine. The wind sweeping device automatically comprises a sweeping wind rod assembly 8, and the wind sweeping rod assembly 8 comprises a wind sweeping drum 82, and a wind sweeping rod shaft 81 installed in the cylinder, and the wind sweeping rod shaft 81 ends stretch out the wind sweeping drum 82, and One end of the swing arm 5 on both sides is connected, and the other end of the swing arm 5 is hinged to the cutter arm 10 of the cutter assembly via the swing arm connecting shaft 7 .

[0029] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com