Improved multilayer circuit board and manufacturing method thereof

A multi-layer circuit board and manufacturing method technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, circuit lamination, etc., can solve the problems of outer layer copper foil wrinkles, poor flatness, etc., to ensure yield and flatness High, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

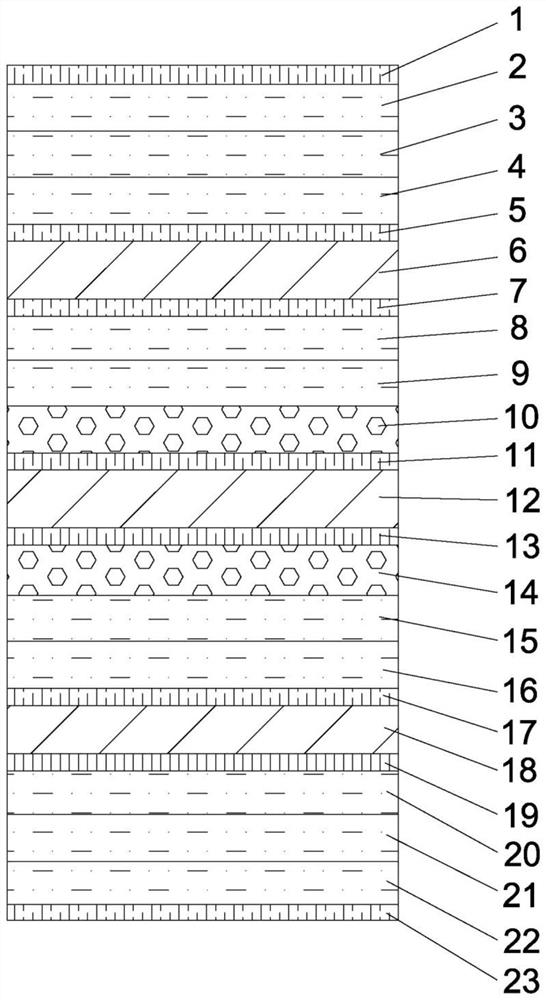

[0028] refer to figure 1 Shown:

[0029] A method for manufacturing a multilayer circuit board, comprising the steps of:

[0030] S1 Production of the first inner layer board: prepare the first inner layer board 6, the upper and lower ends of the first inner layer board 6 are electroplated, dry filmed and etched to form the first inner layer copper foil 5 and the second inner layer copper foil 7 respectively , the residual copper rate of the first inner layer copper foil 5 and the second inner layer copper foil 7 after etching is 56%;

[0031] S2 Production of the second inner layer board: prepare the second inner layer board 12, the upper and lower ends of the second inner layer board 12 are electroplated, dry filmed and etched to form the third inner layer copper foil 11 and the fourth inner layer copper foil 13 respectively , the residual copper rate of the third inner layer copper foil 11 after etching is 51%, and the residual copper rate of the fourth inner layer copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com