Patents

Literature

48results about "Patterning and lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

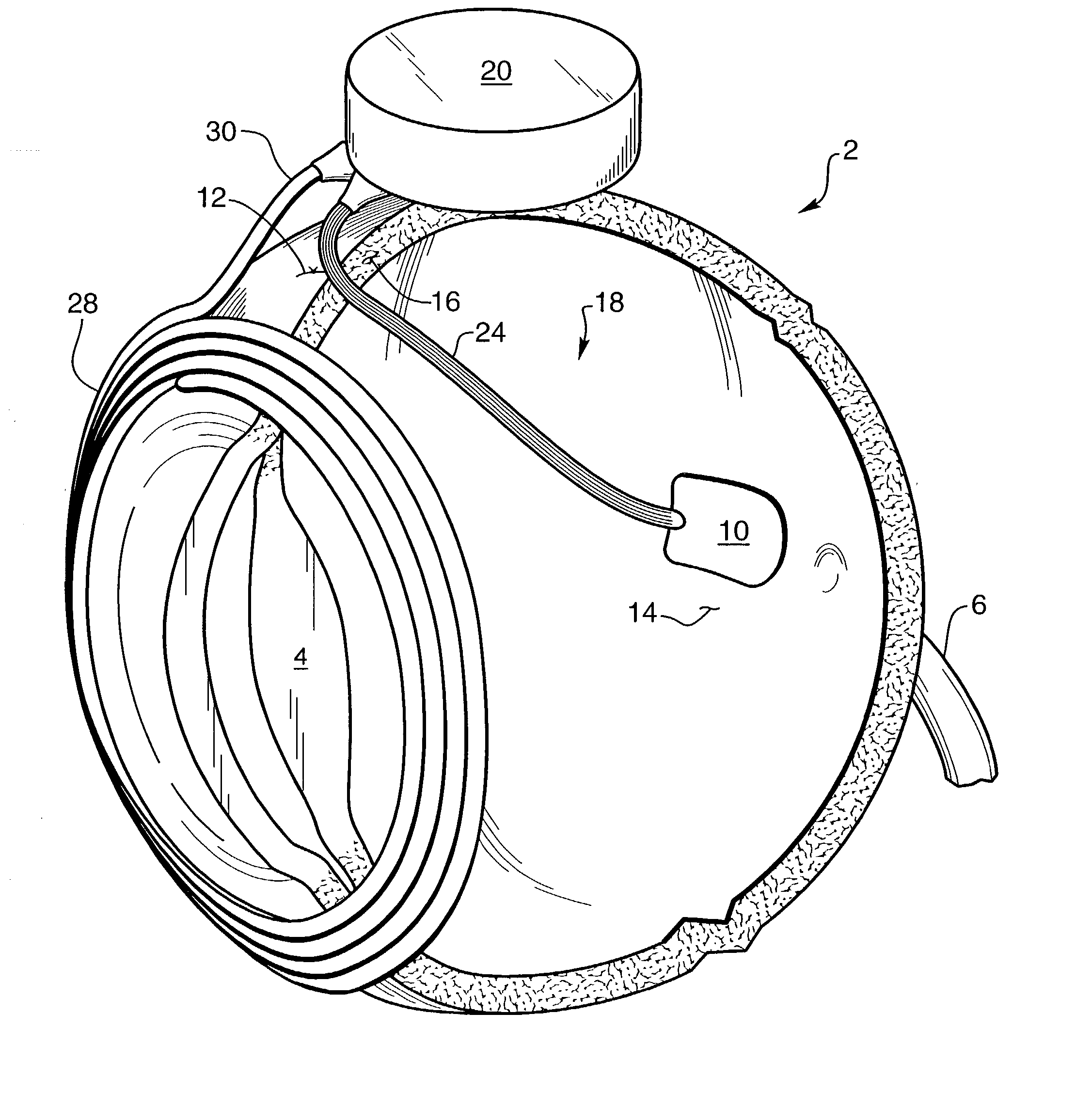

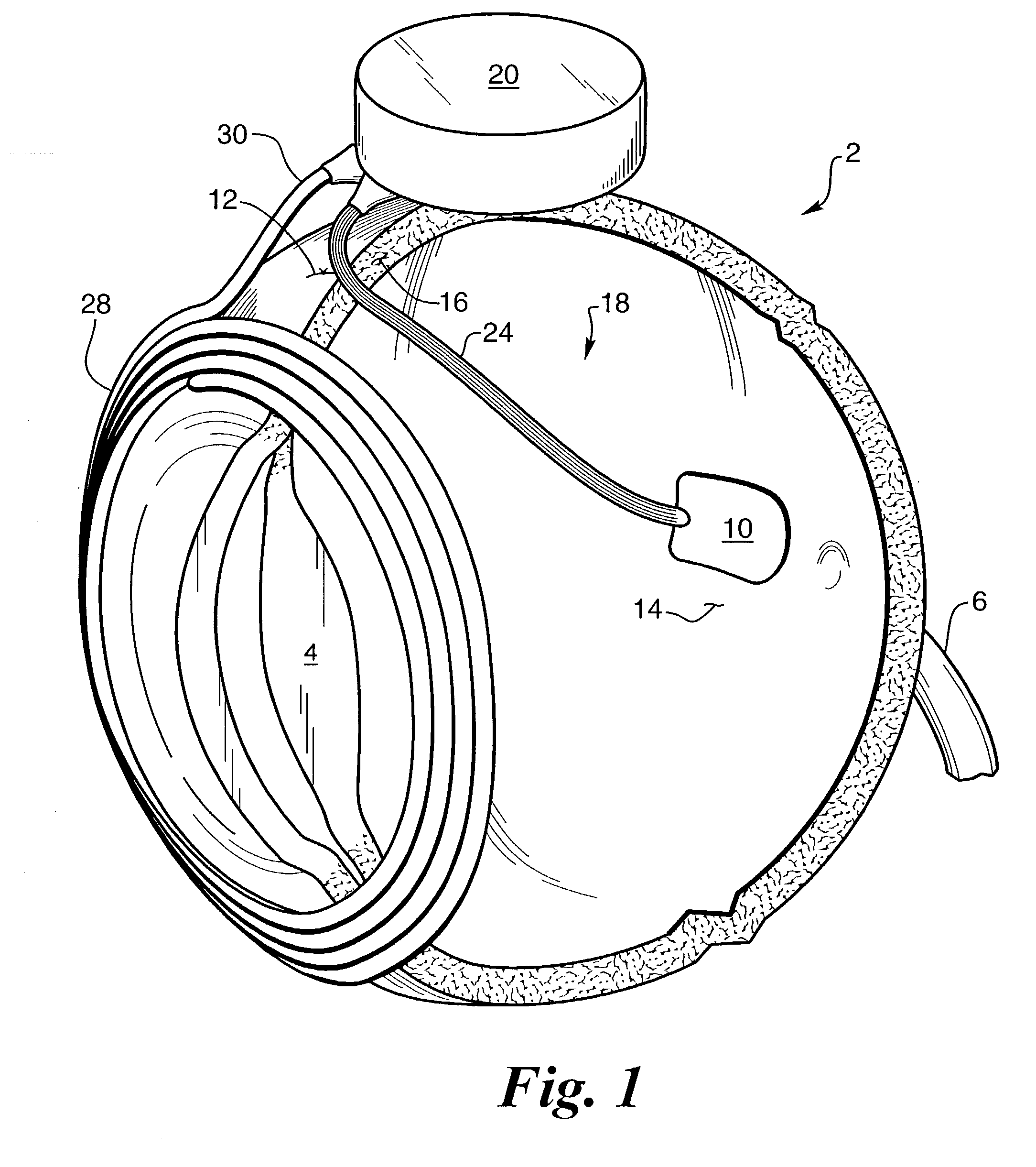

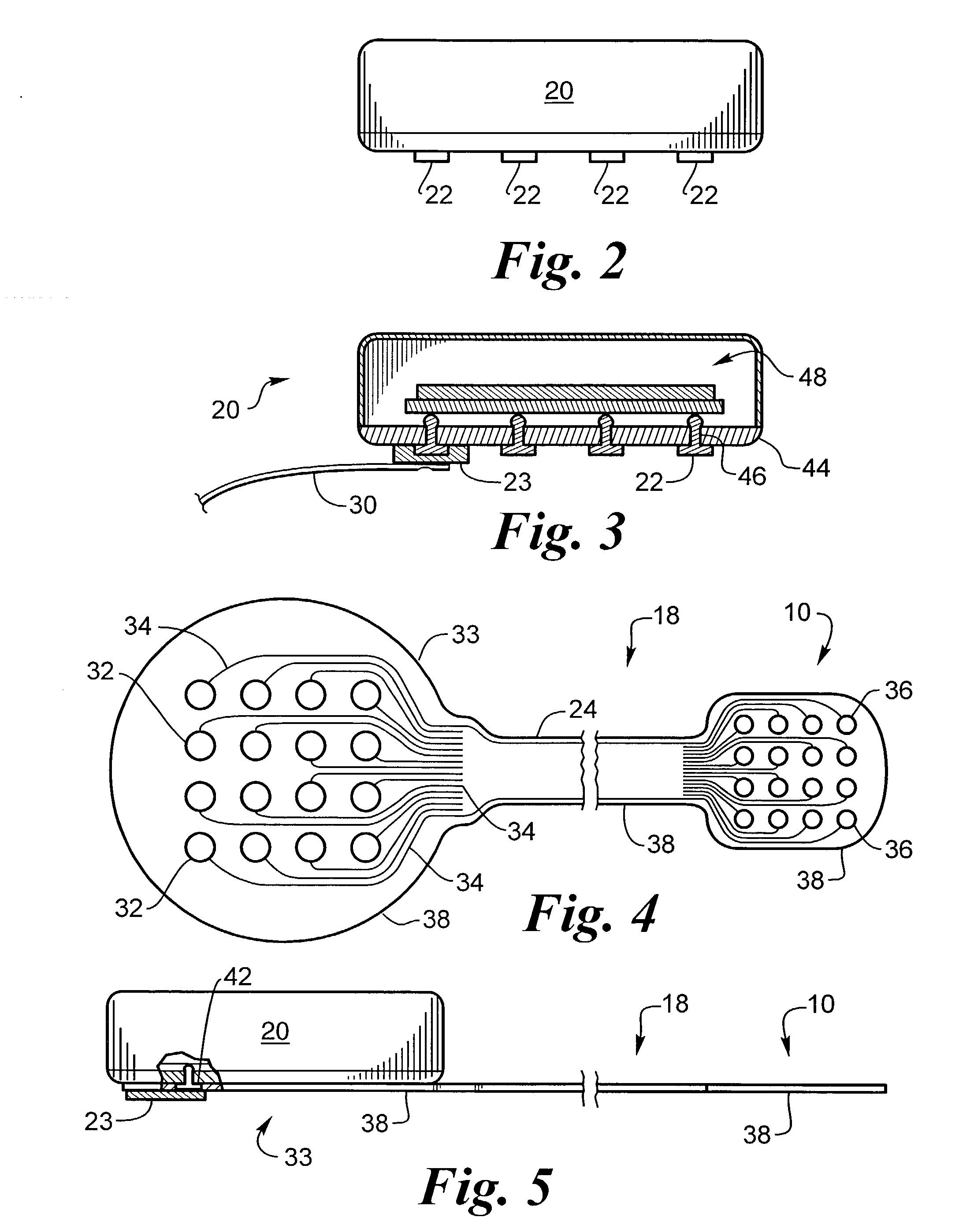

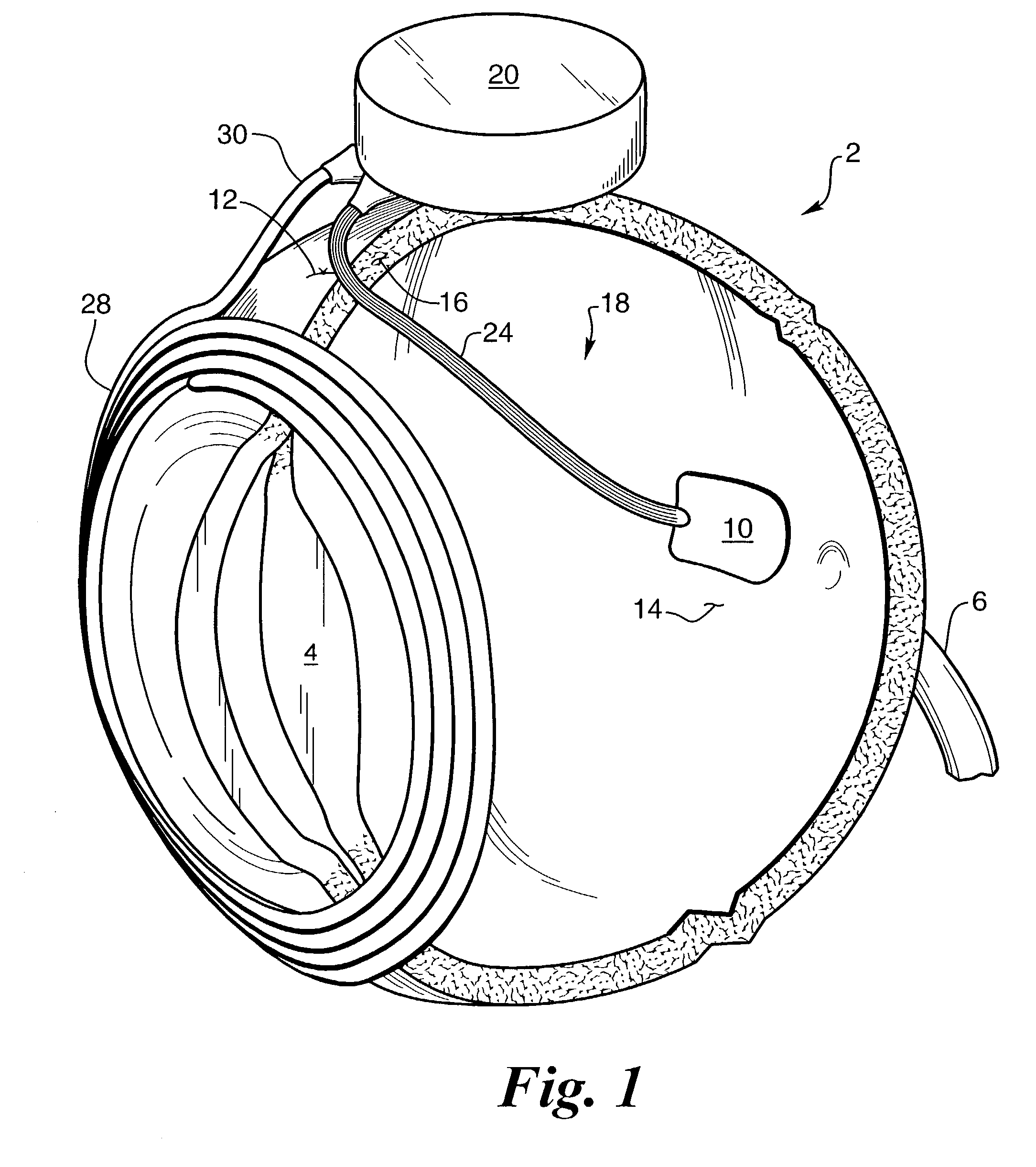

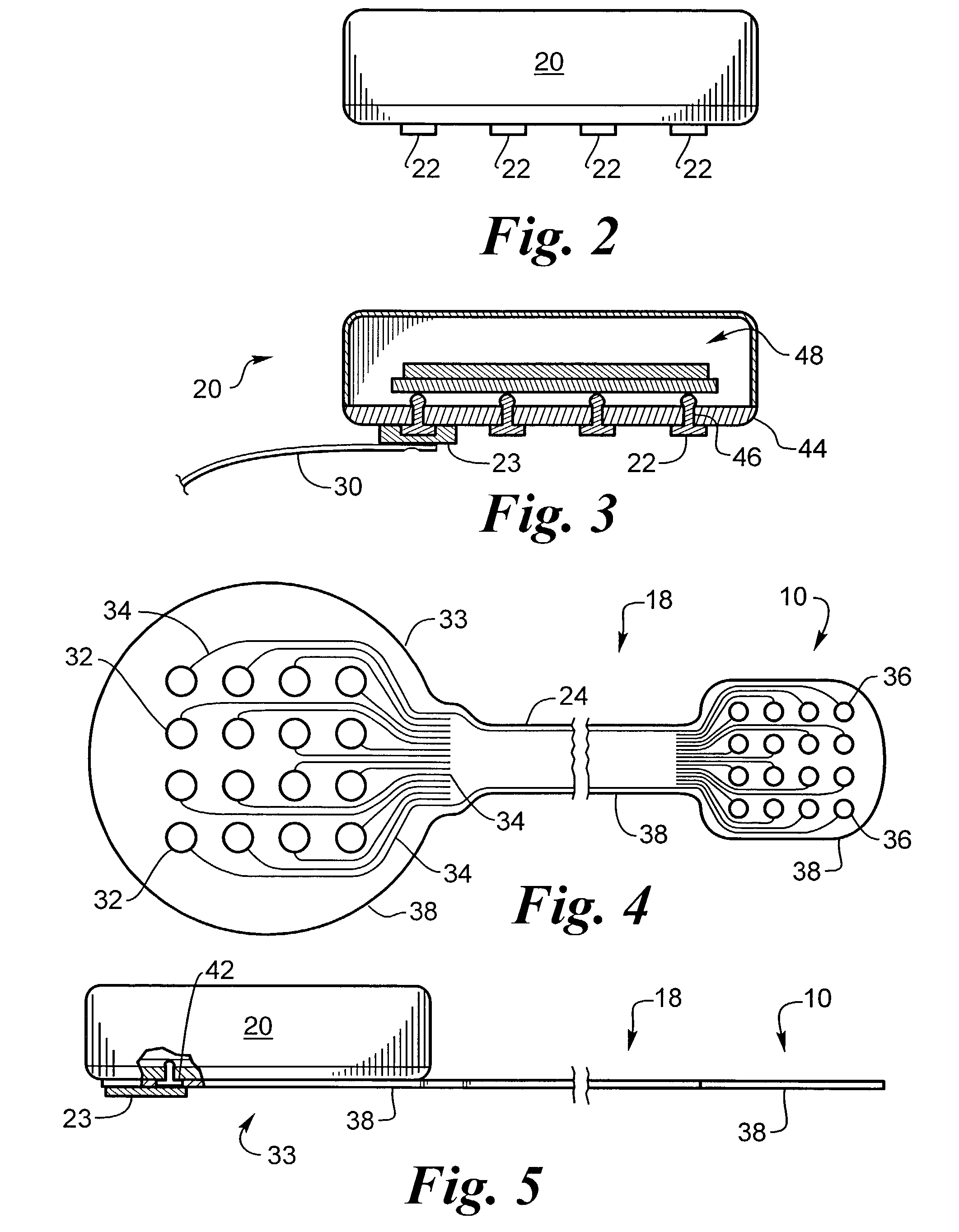

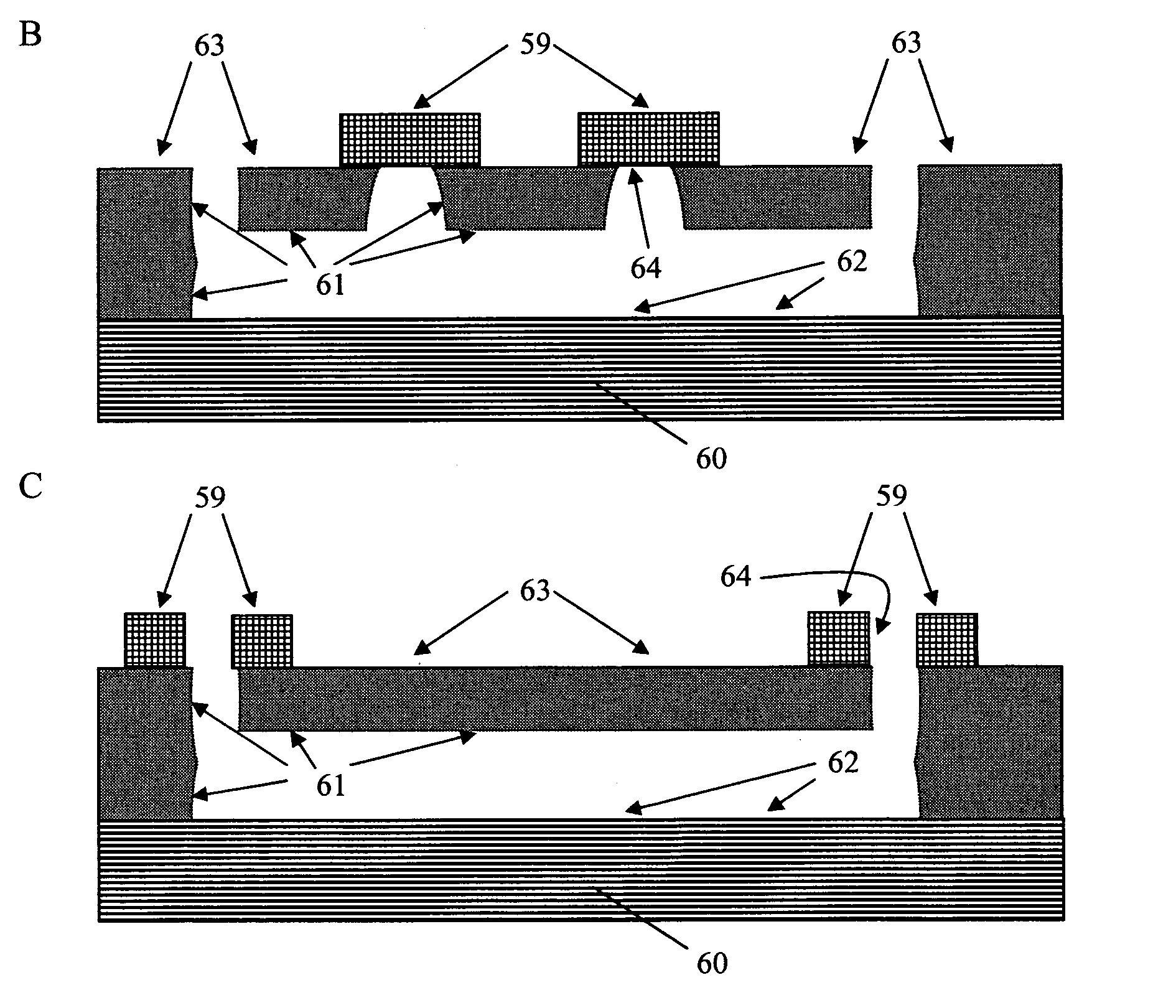

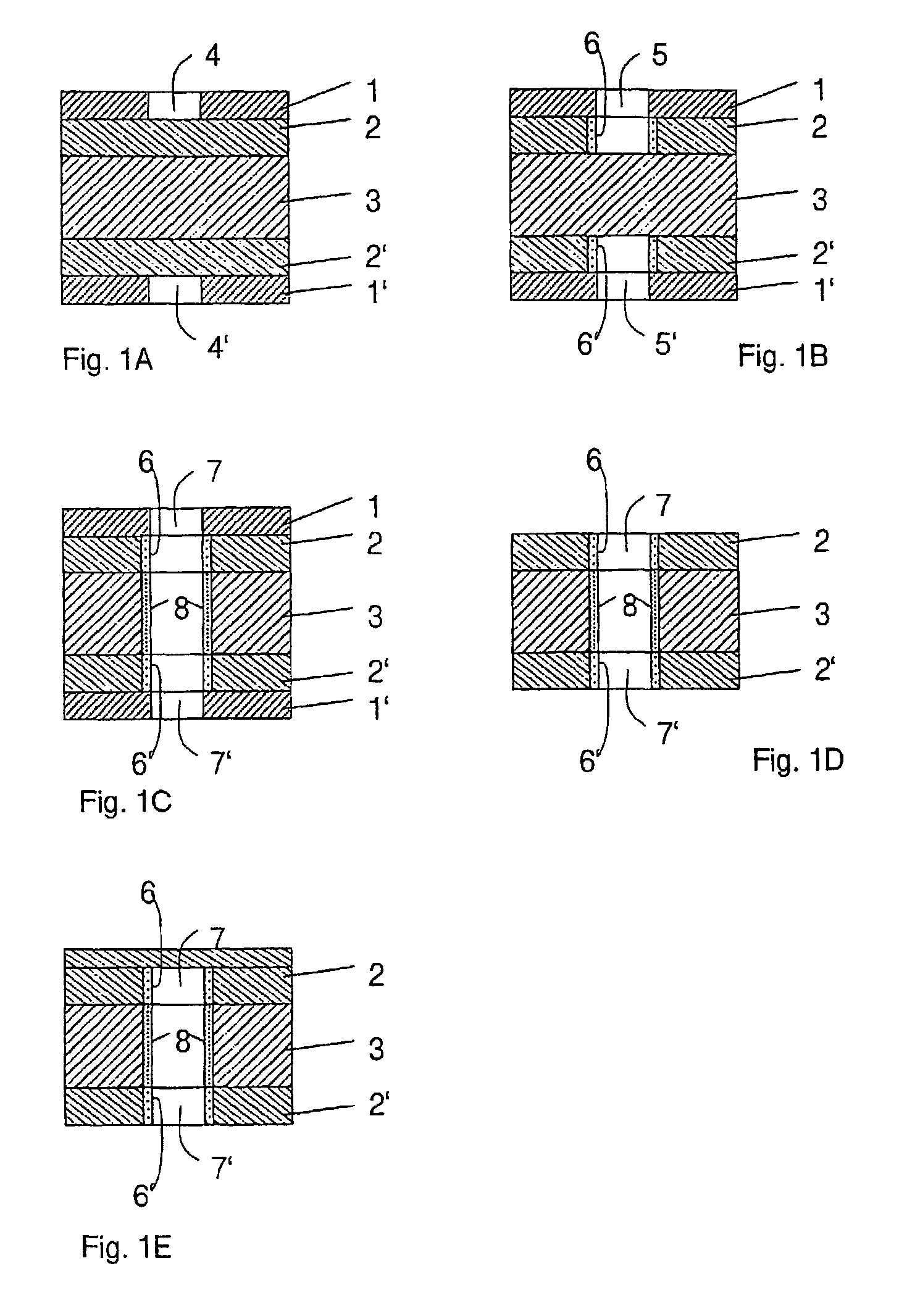

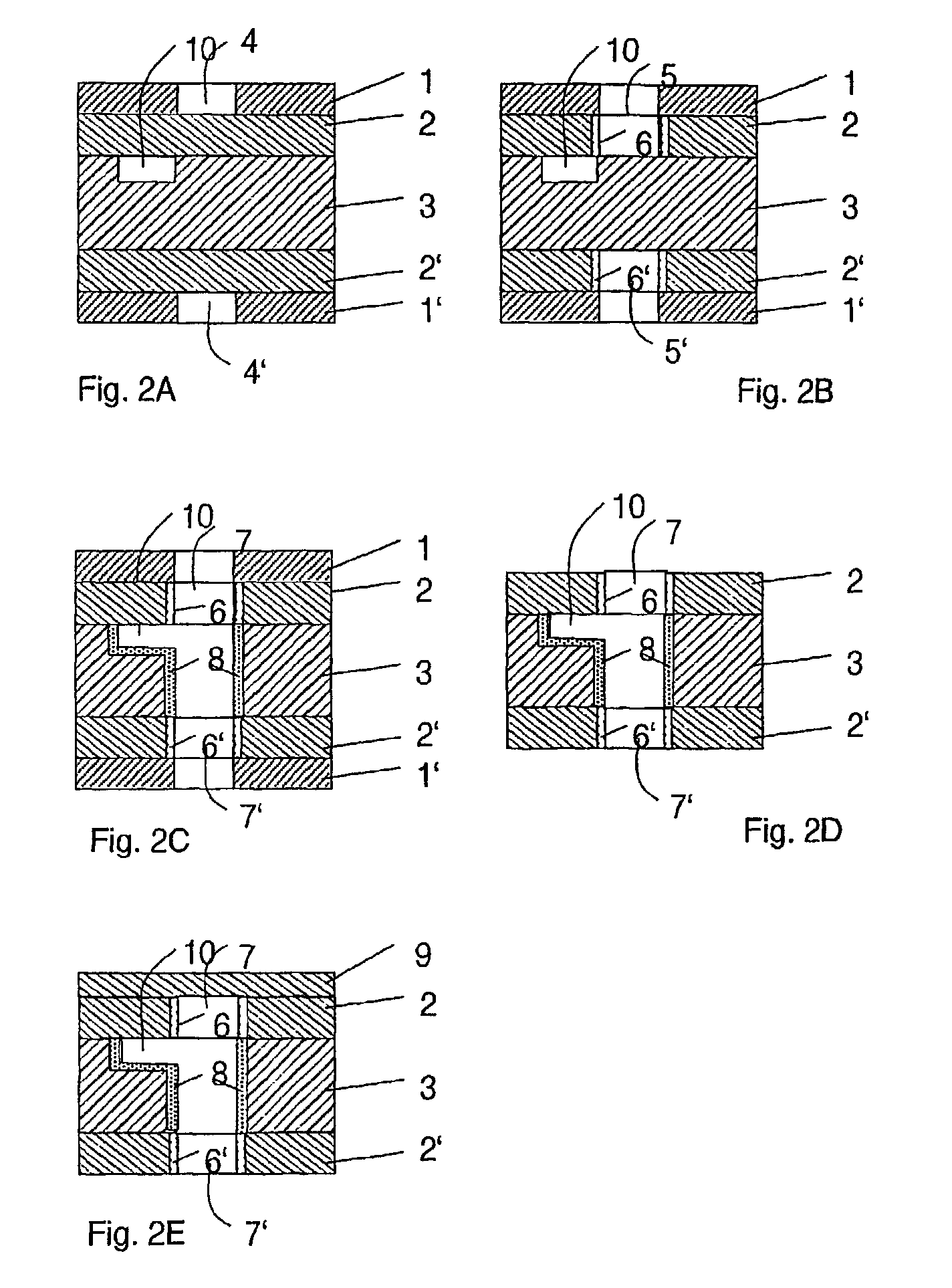

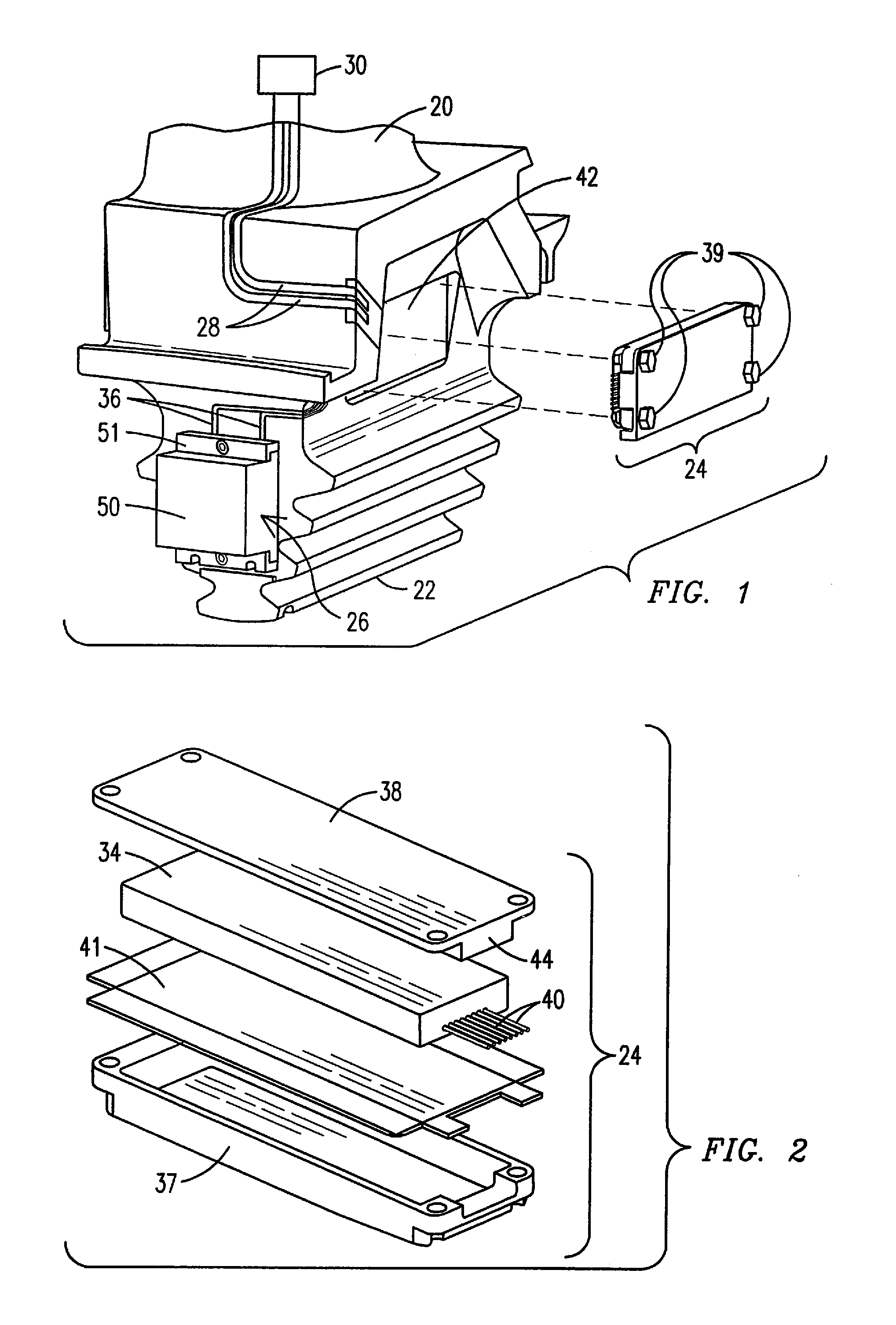

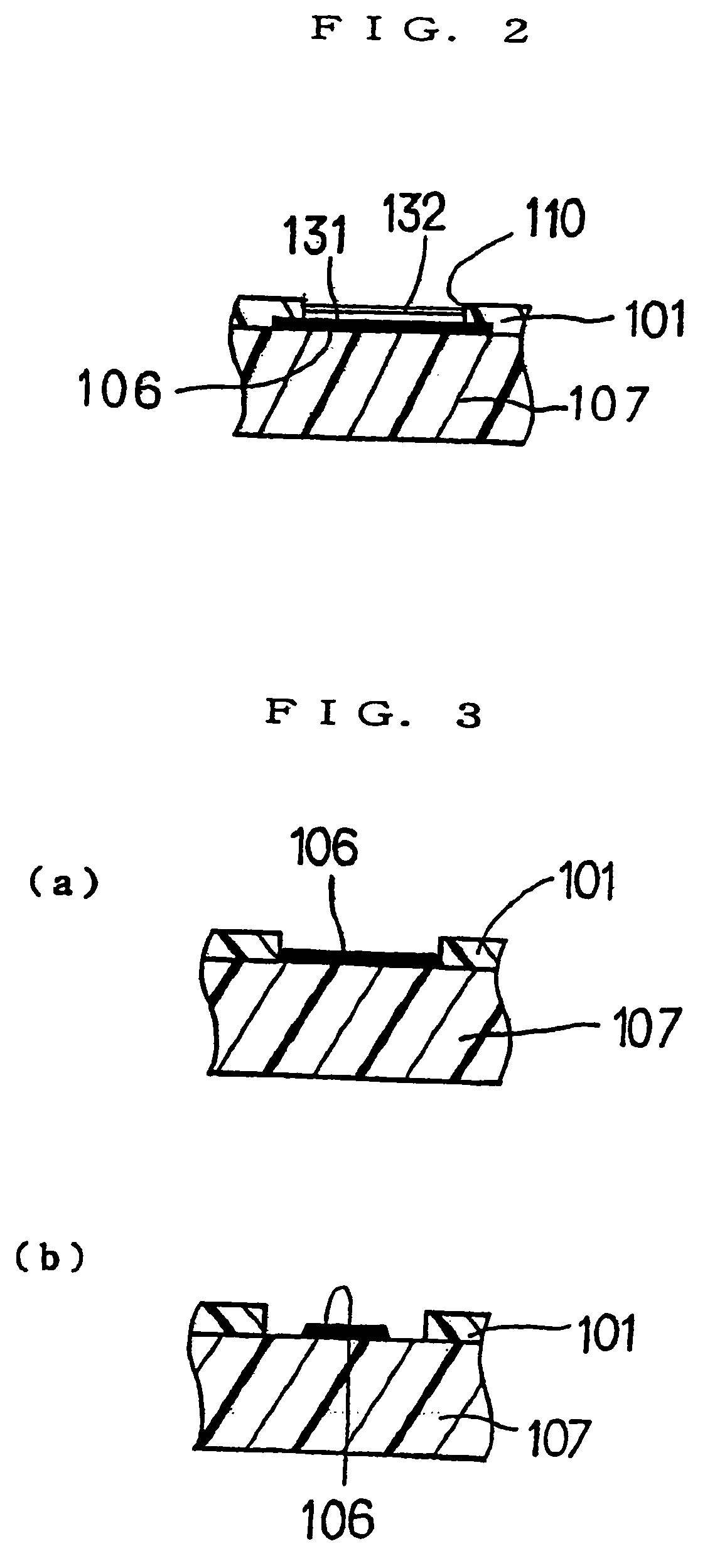

Biocompatible bonding method and electronics package suitable for implantation

ActiveUS20030233134A1Uniform propertySemiconductor/solid-state device detailsSolid-state devicesFlexible circuitsHermetic seal

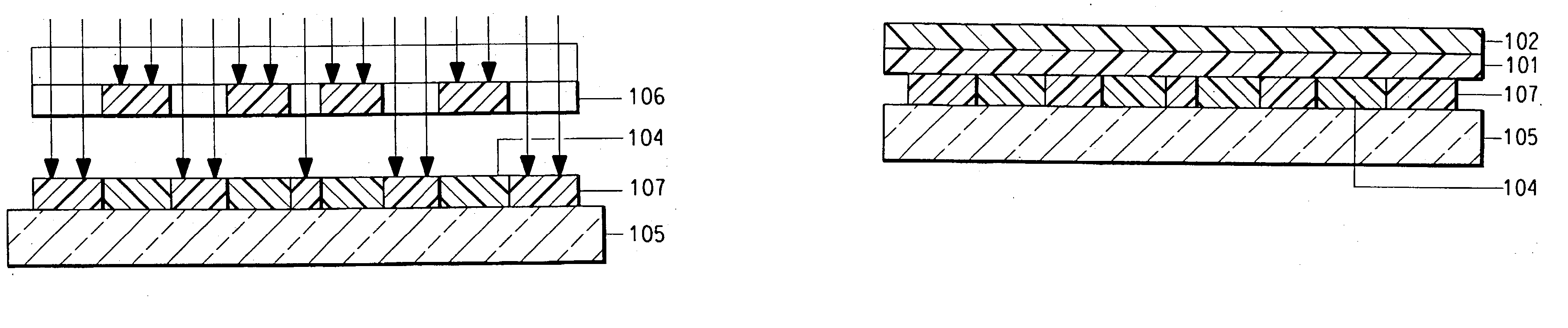

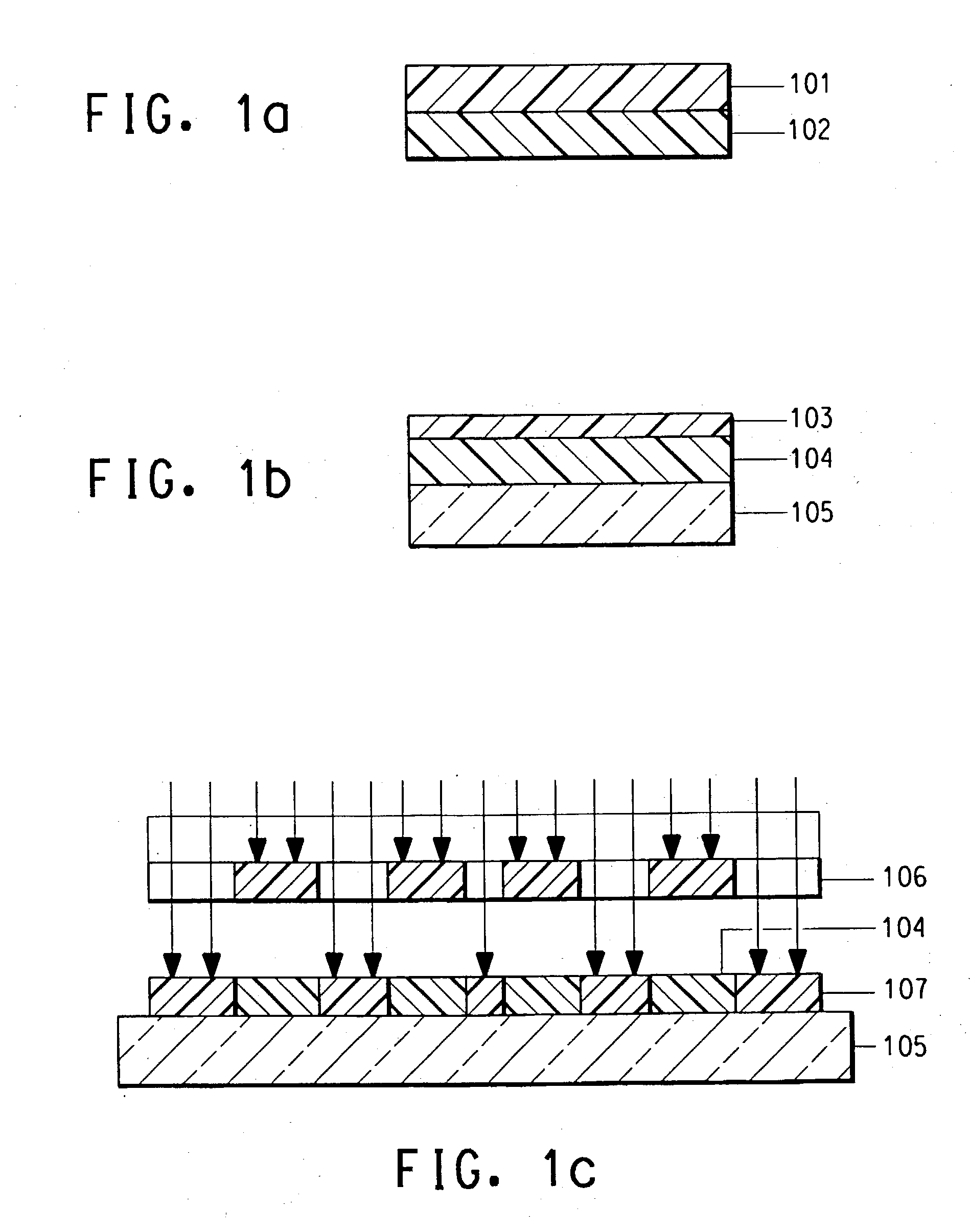

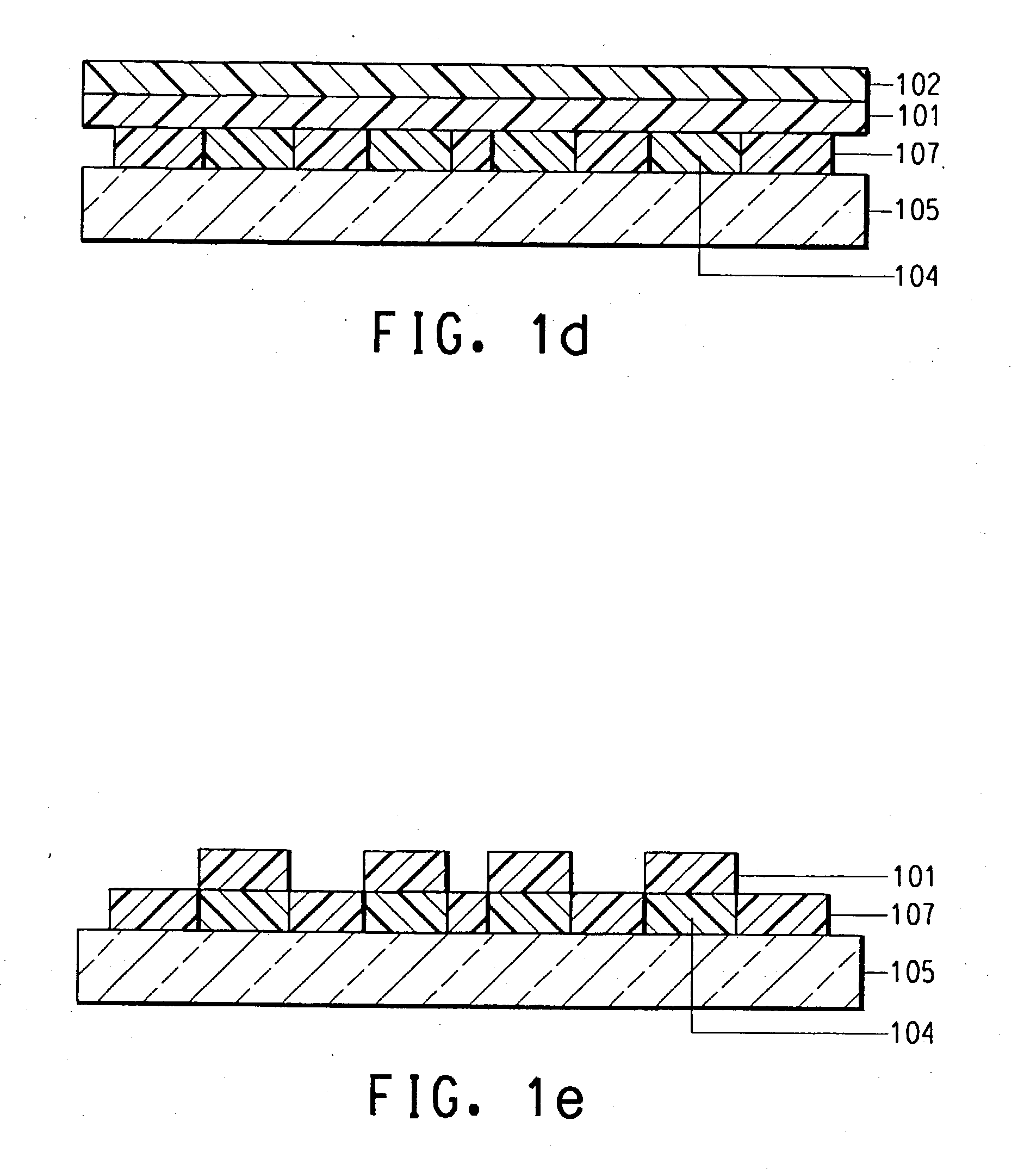

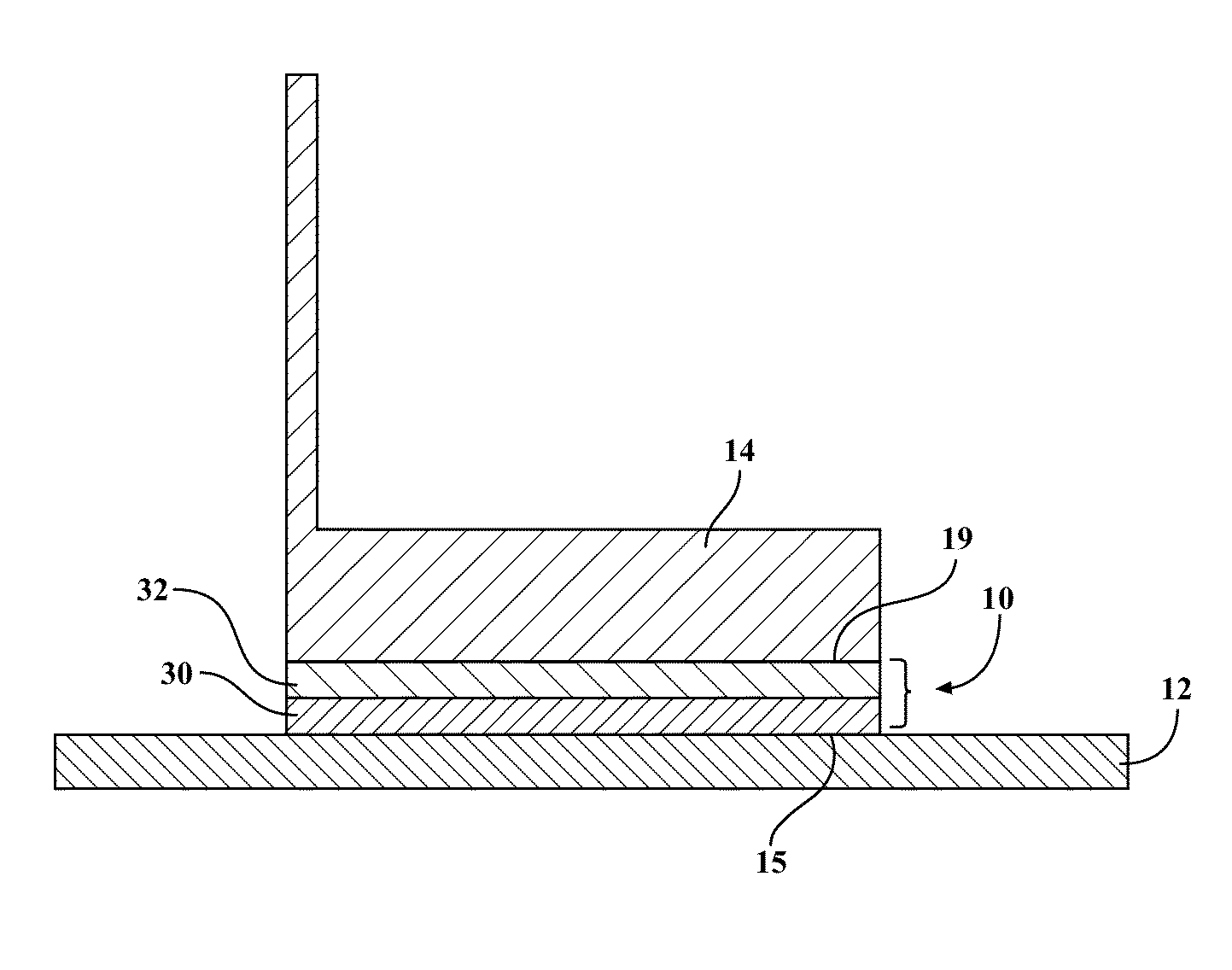

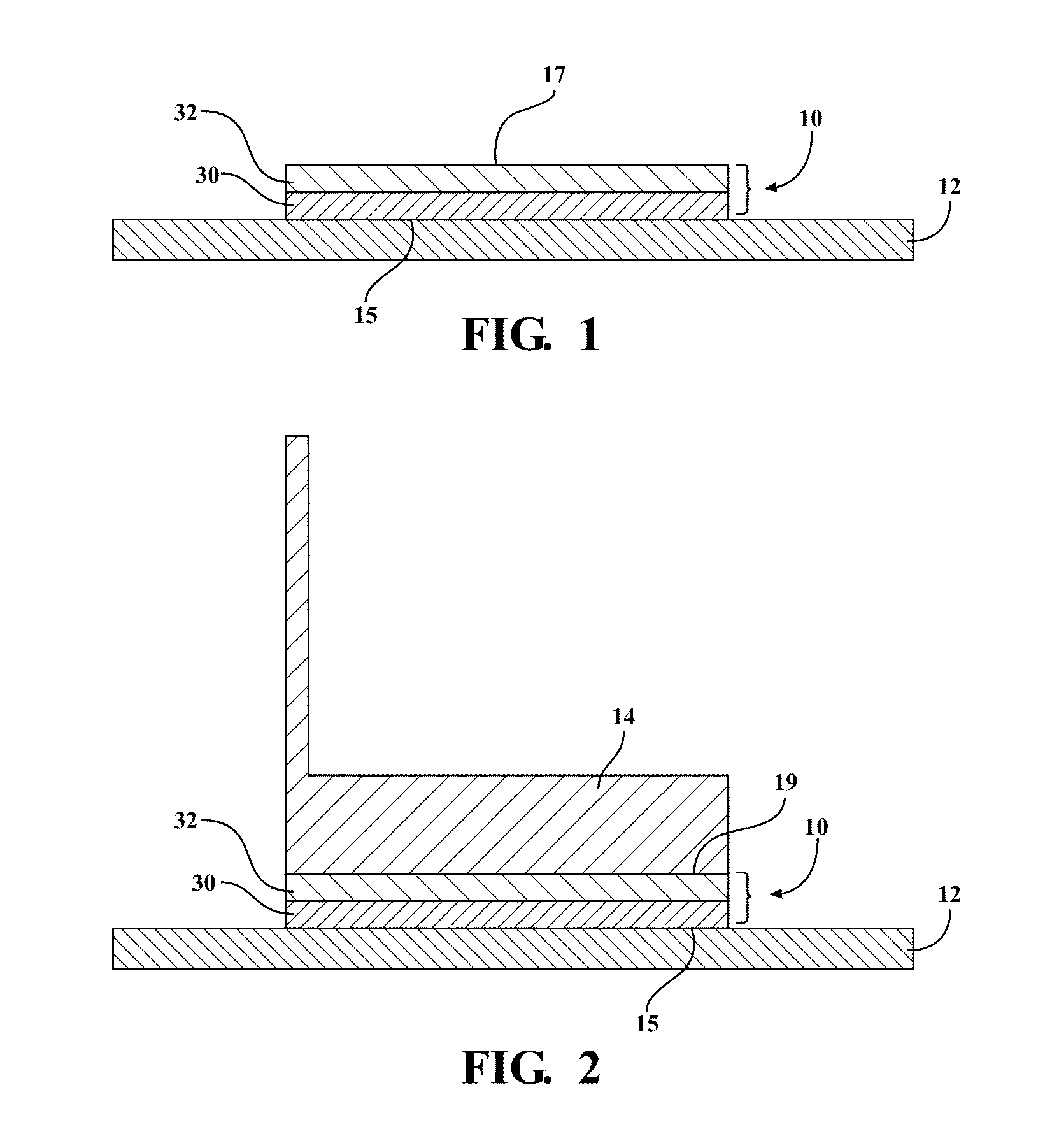

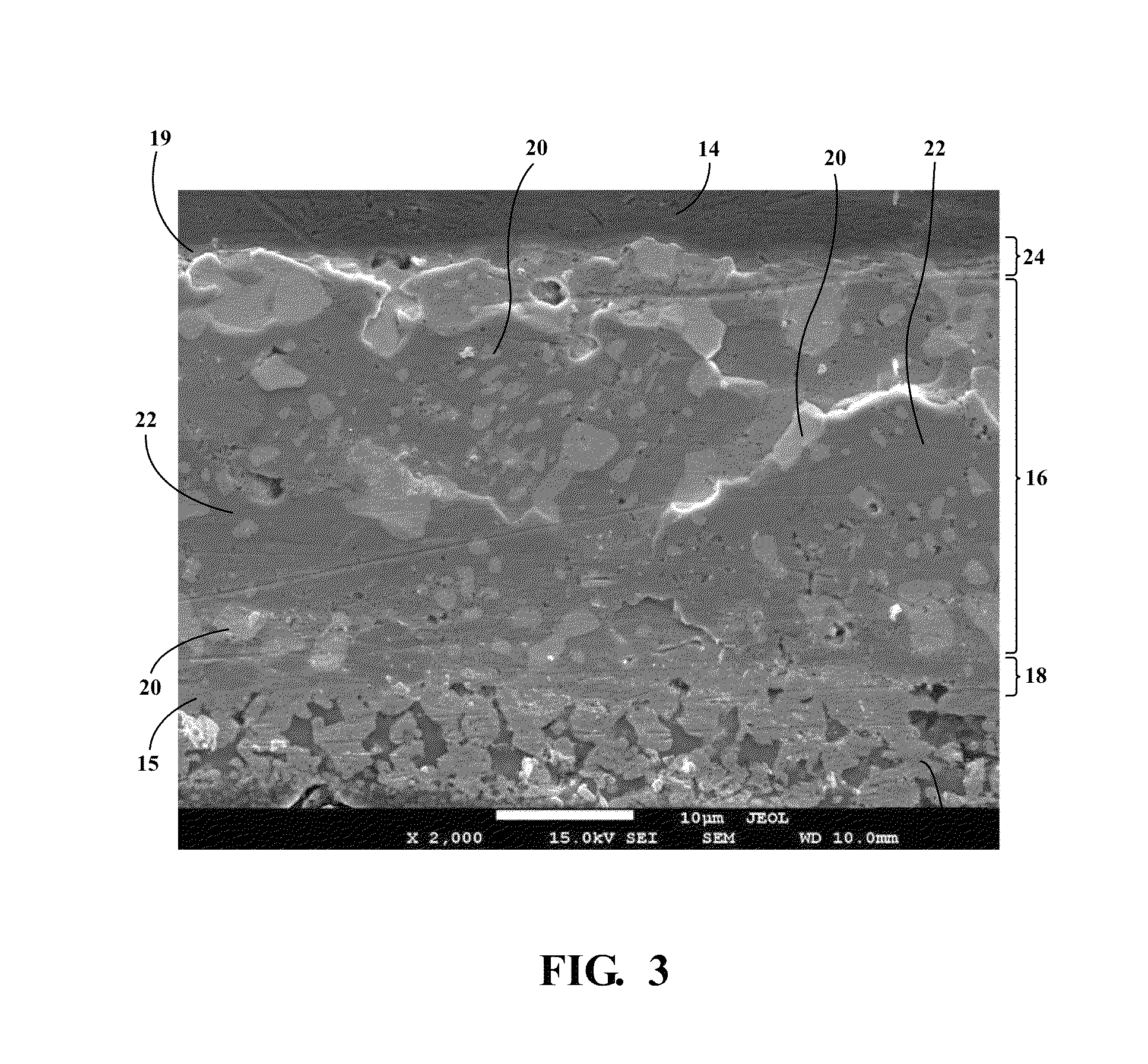

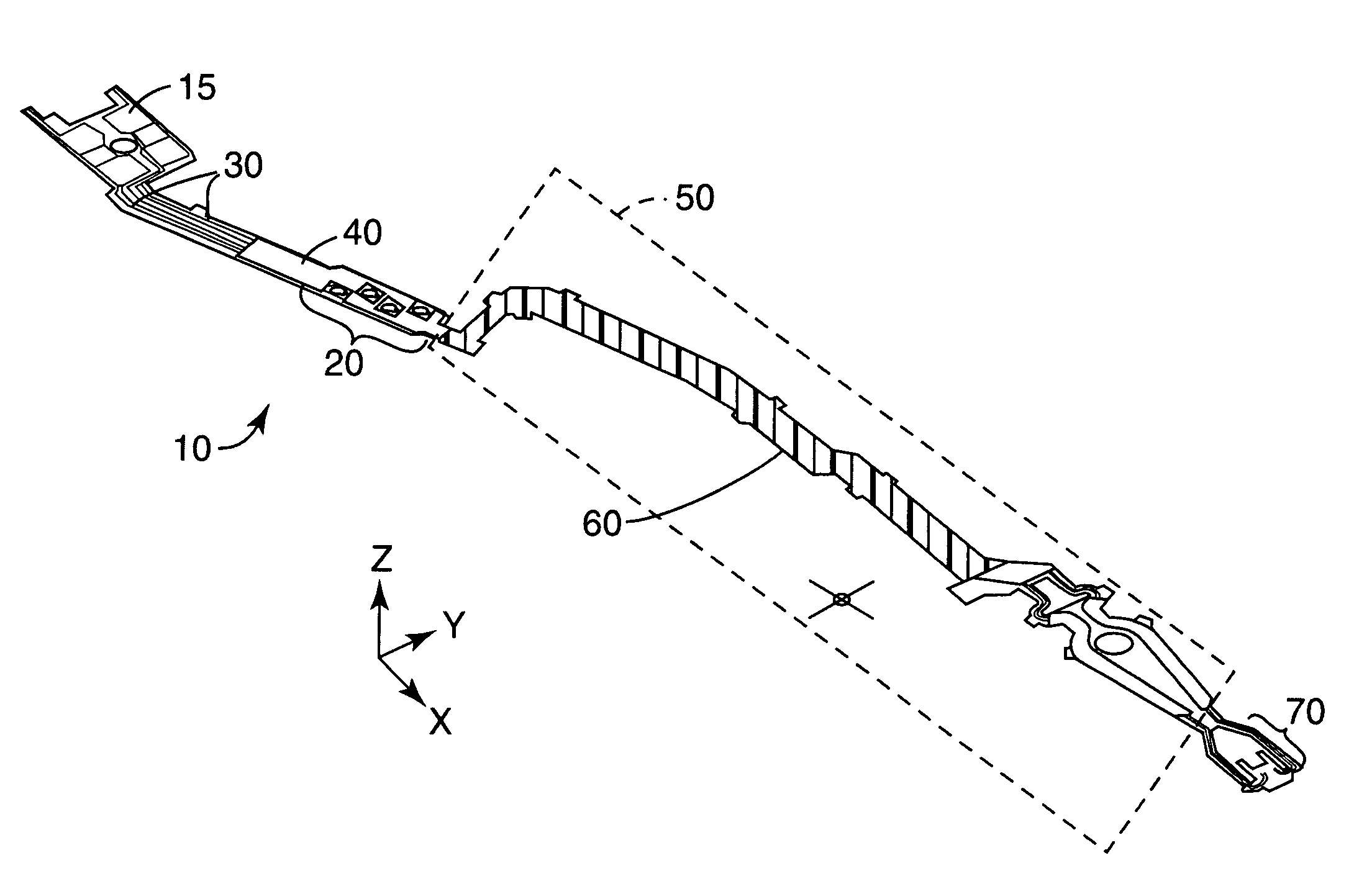

The invention is directed to a method of bonding a hermetically sealed electronics package to an electrode or a flexible circuit and the resulting electronics package, that is suitable for implantation in living tissue, such as for a retinal or cortical electrode array to enable restoration of sight to certain non-sighted individuals. The hermetically sealed electronics package is directly bonded to the flex circuit or electrode by electroplating a biocompatible material, such as platinum or gold, effectively forming a plated rivet-shaped connection, which bonds the flex circuit to the electronics package. The resulting electronic device is biocompatible and is suitable for long-term implantation in living tissue.

Owner:CORTIGENT INC +1

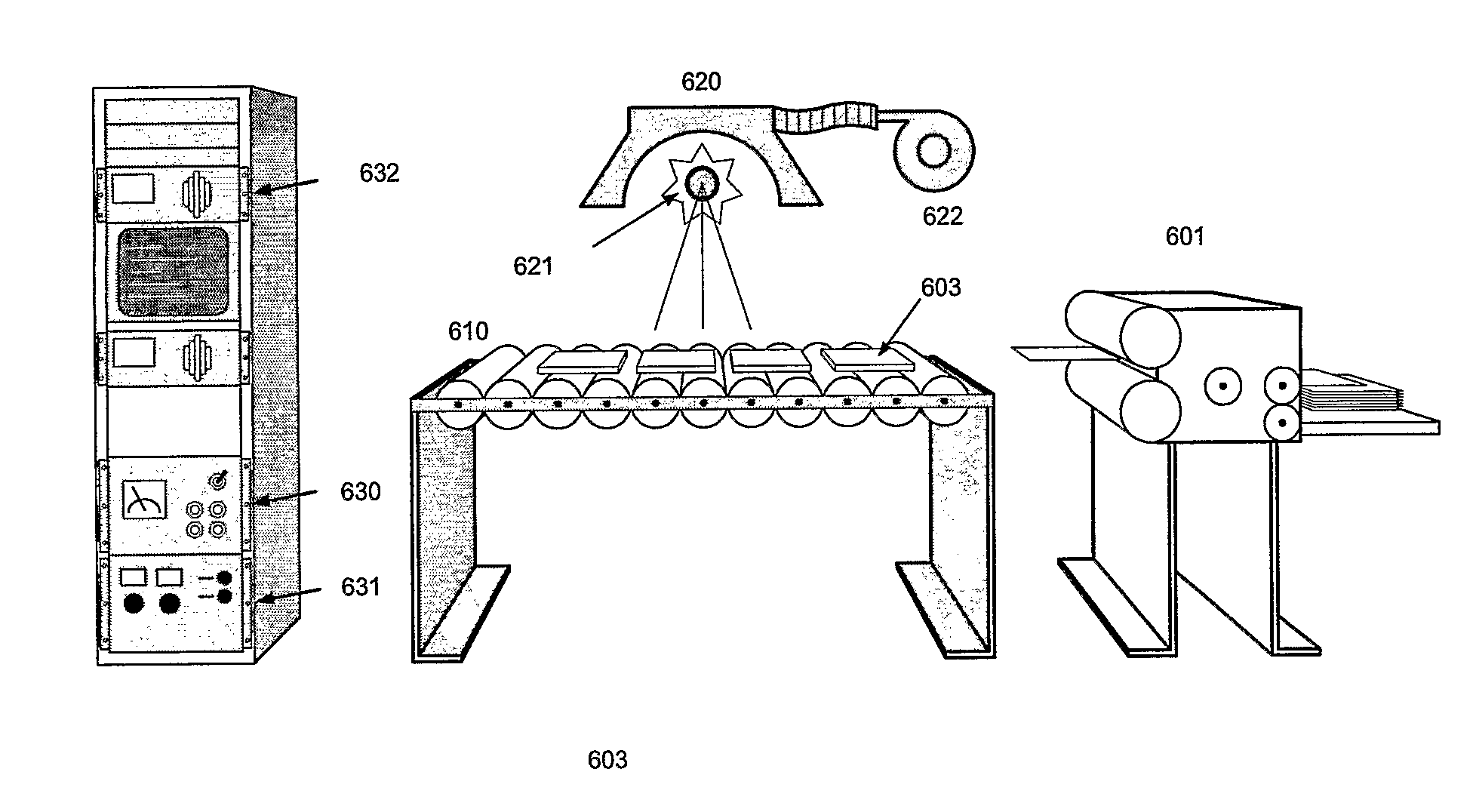

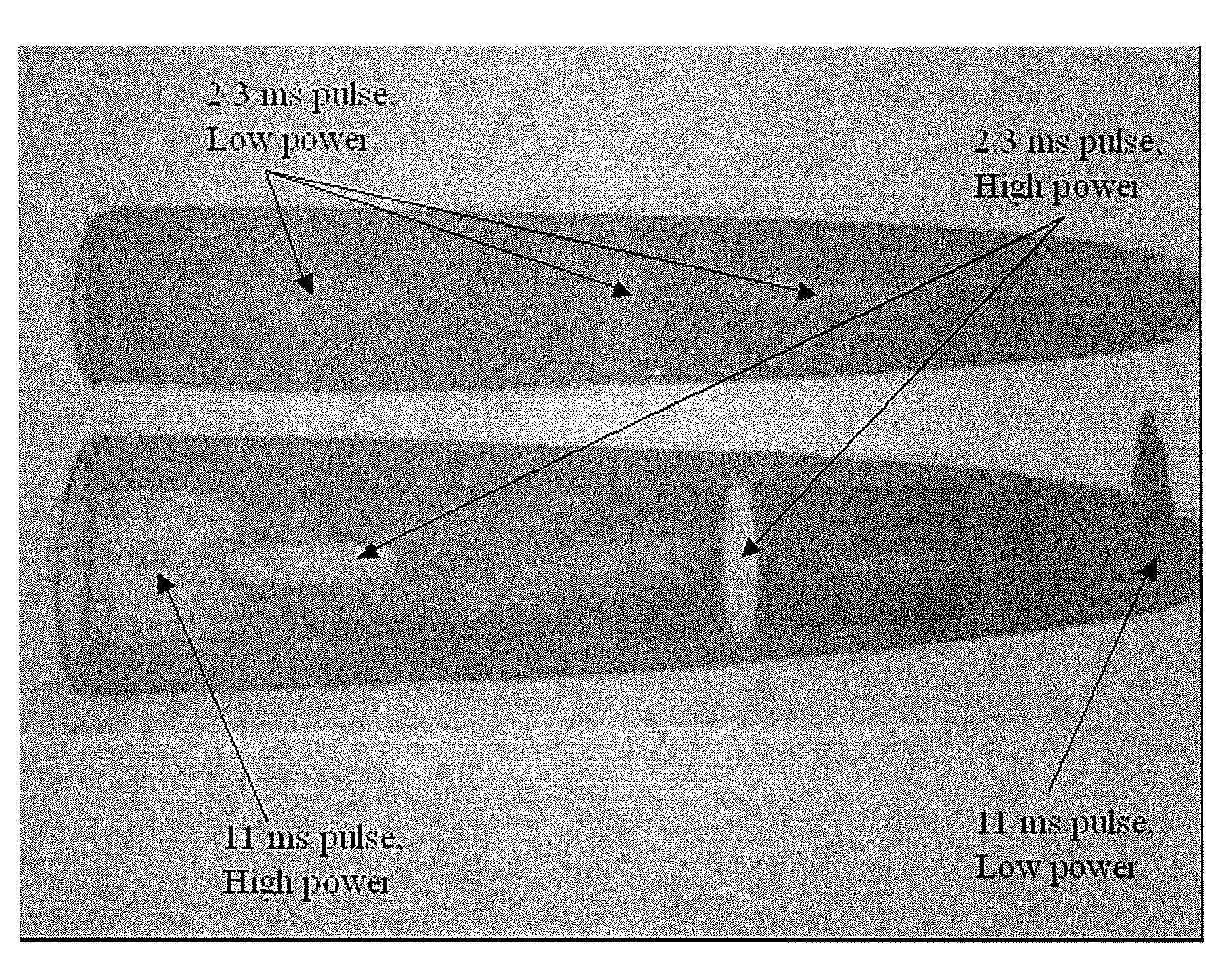

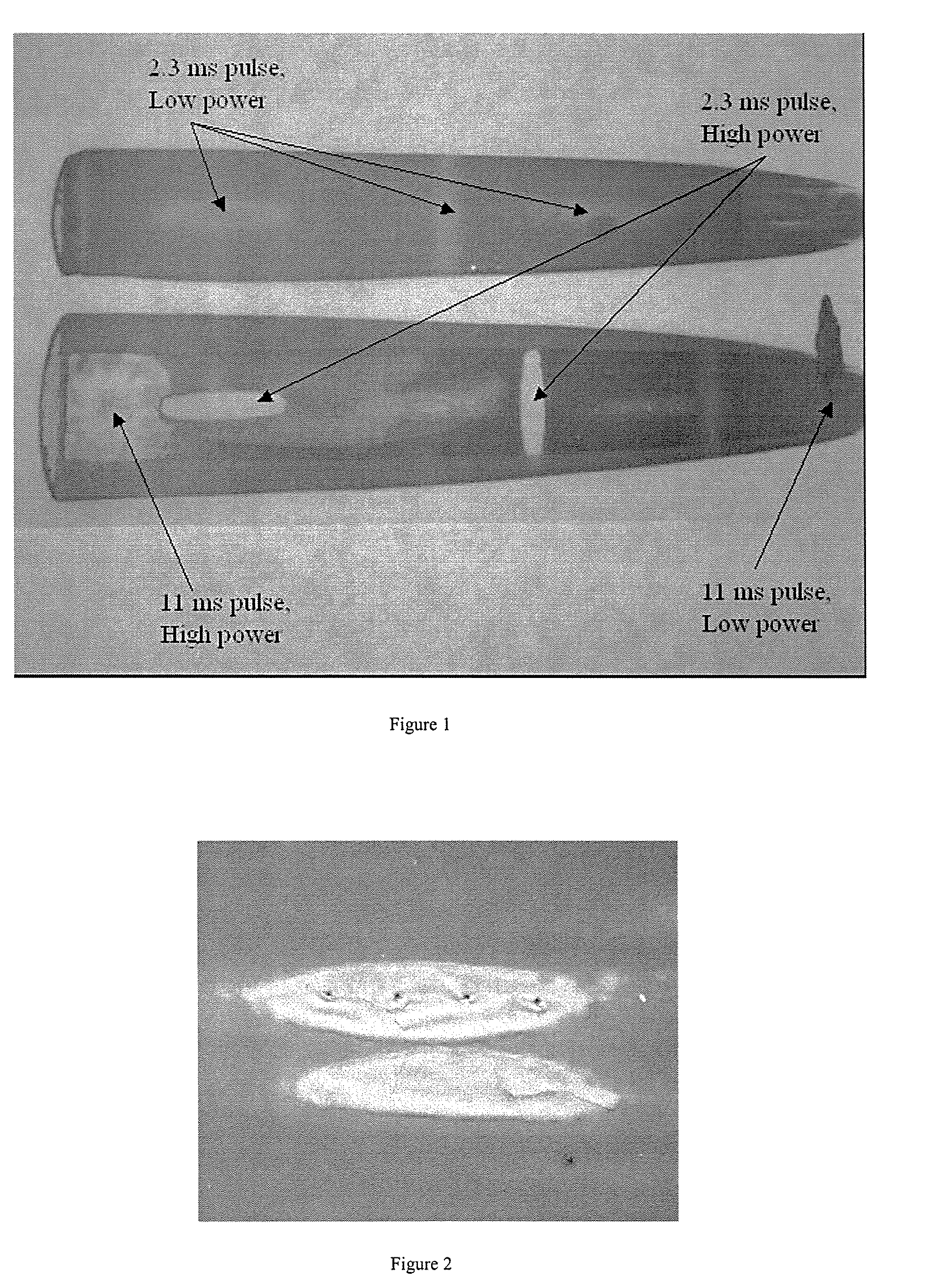

Electrical, Plating And Catalytic Uses Of Metal Nanomaterial Compositions

ActiveUS20080020304A1Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

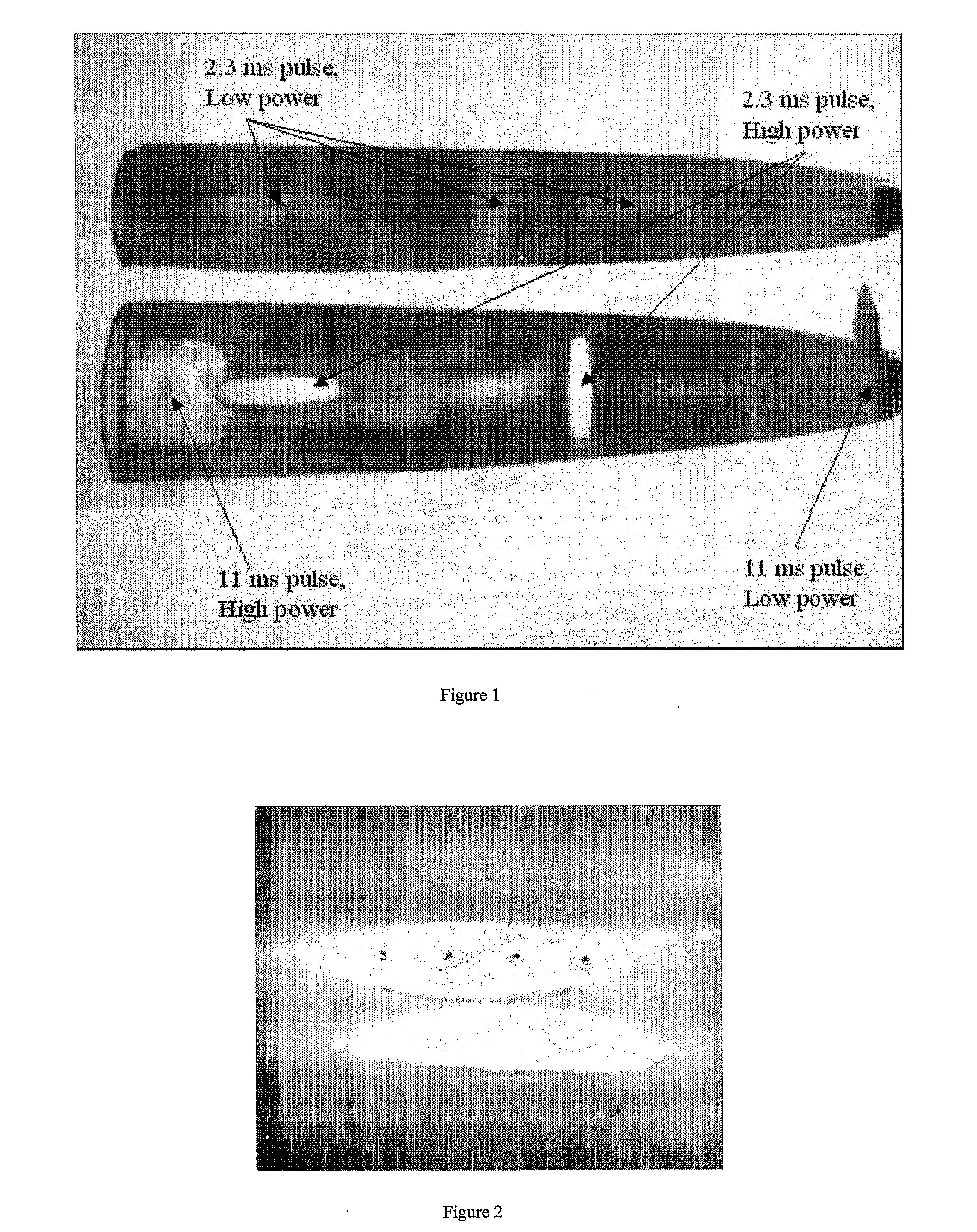

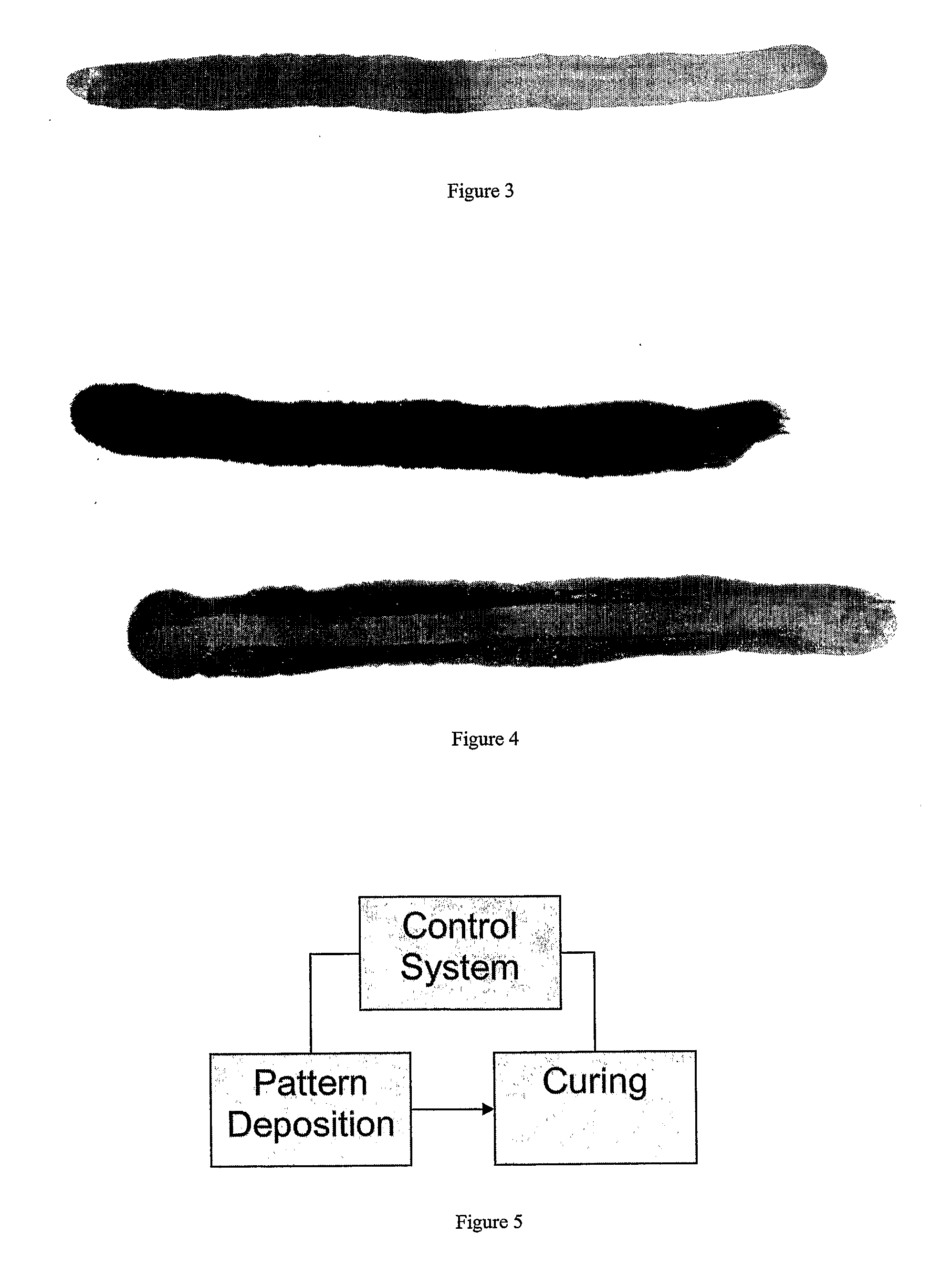

This invention relates generally to uses of novel nanomaterial composition and the systems in which they are used, and more particularly to nanomaterial compositions generally comprising carbon and a metal, which composition can be exposed to pulsed emissions to react, activate, combine, or sinter the nanomaterial composition. The nanomaterial compositions can alternatively be utilized at ambient temperature or under other means to cause such reaction, activation, combination, or sintering to occur.

Owner:NCC NANO LLC

Biocompatible bonding method and electronics package suitable for implantation

ActiveUS7142909B2Semiconductor/solid-state device detailsSolid-state devicesFlexible circuitsEngineering

The invention is directed to a method of bonding a hermetically sealed electronics package to an electrode or a flexible circuit and the resulting electronics package, that is suitable for implantation in living tissue, such as for a retinal or cortical electrode array to enable restoration of sight to certain non-sighted individuals. The hermetically sealed electronics package is directly bonded to the flex circuit or electrode by electroplating a biocompatible material, such as platinum or gold, effectively forming a plated rivet-shaped connection, which bonds the flex circuit to the electronics package. The resulting electronic device is biocompatible and is suitable for long-term implantation in living tissue.

Owner:CORTIGENT INC +1

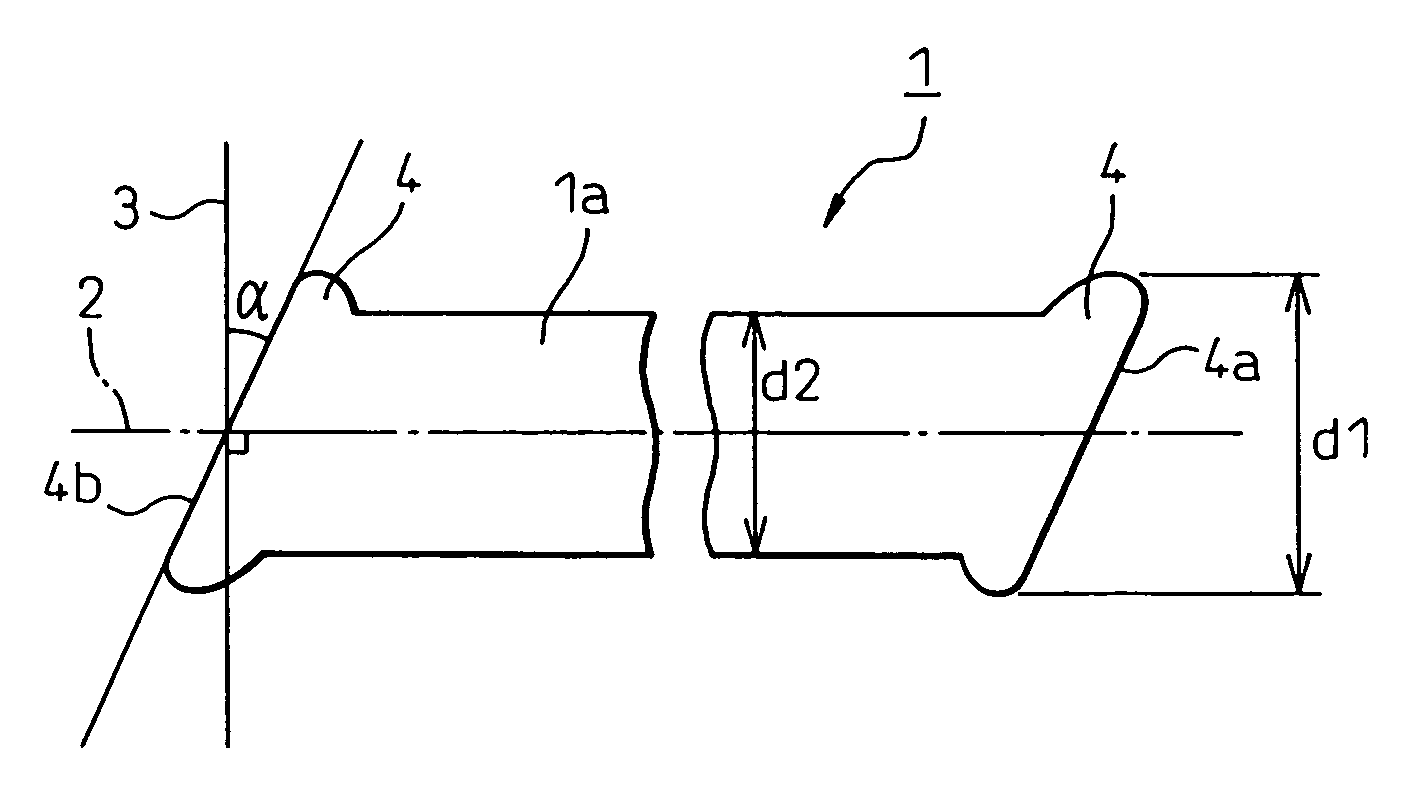

Heat-resistant synthetic fiber sheet

InactiveUS7026033B2Improve heat resistanceNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceOrganic synthesis

A heat-resistant fiber paper-like sheet comprises 40 to 97% by mass of heat-resistant organic synthetic polymers staple fibers, 3 to 60% by mass of heat resistant organic synthetic polymer fibrid and or an organic resin binder, in a portion of the staple fibers, each staple fiber having two flat end faces having an inclining angle of 10 degrees or more from a plane crossing the fiber axis at a right angles, and is useful as a base material for laminate materials for electrical circuit boards.

Owner:TEIJIN LTD

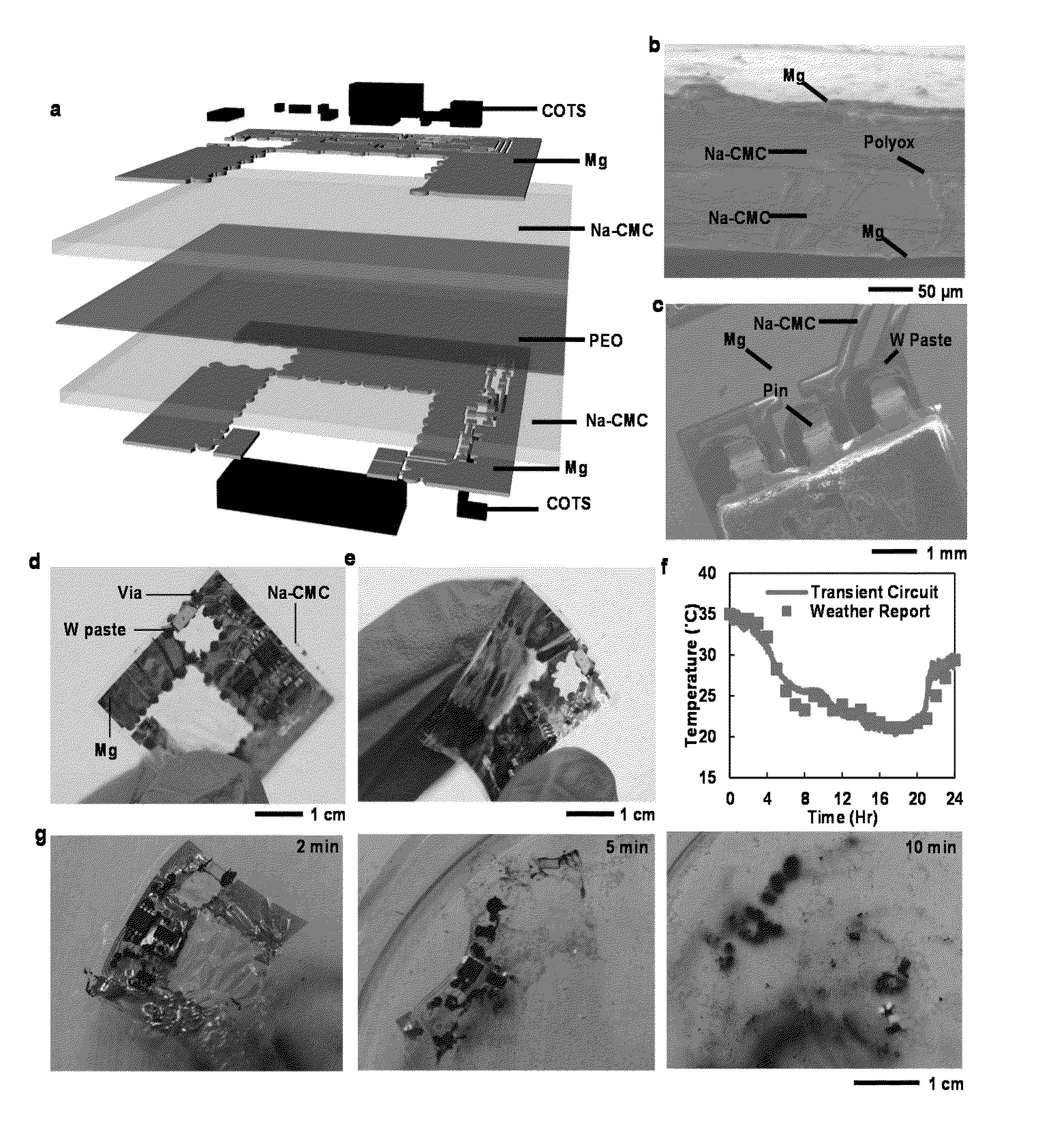

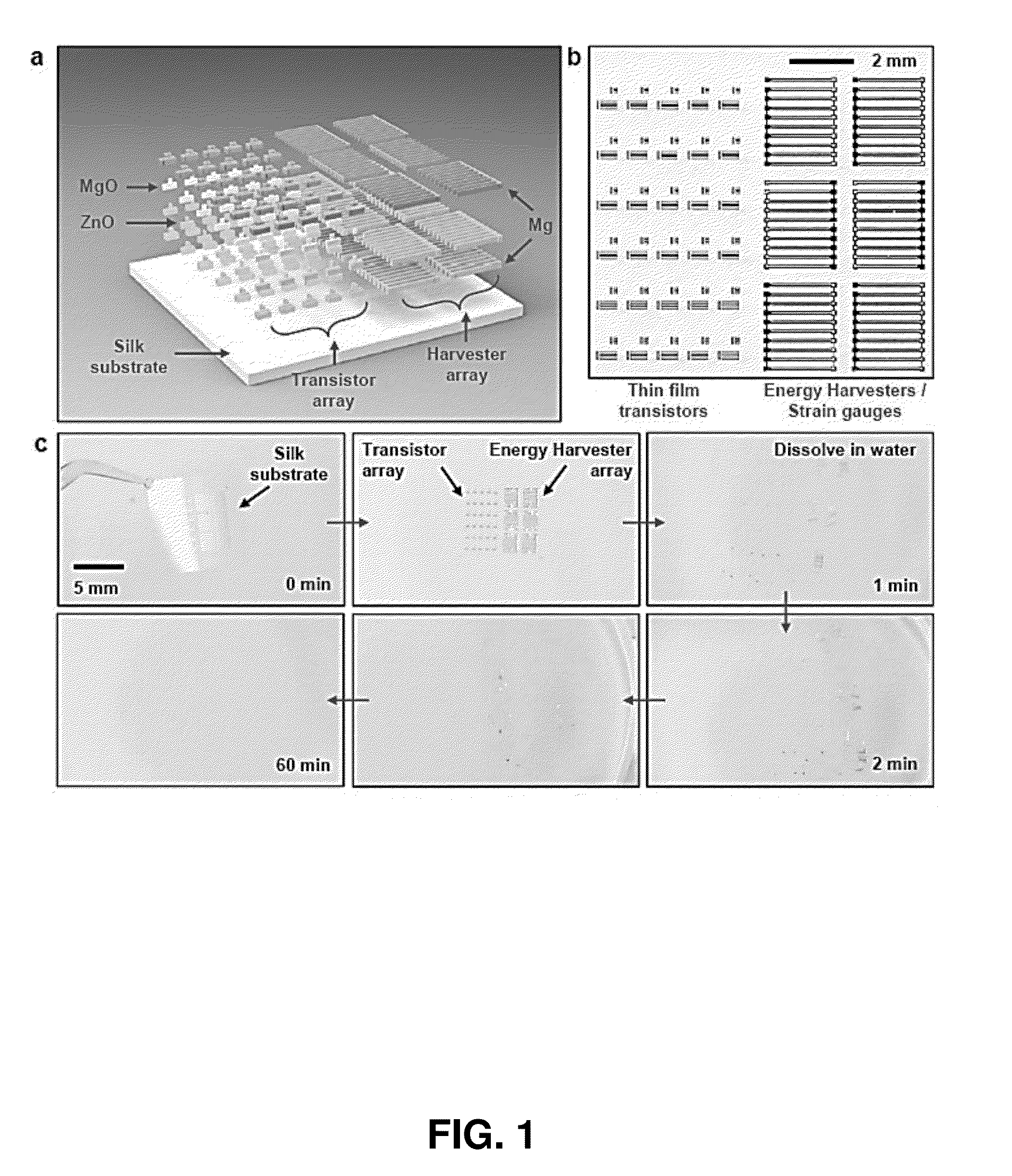

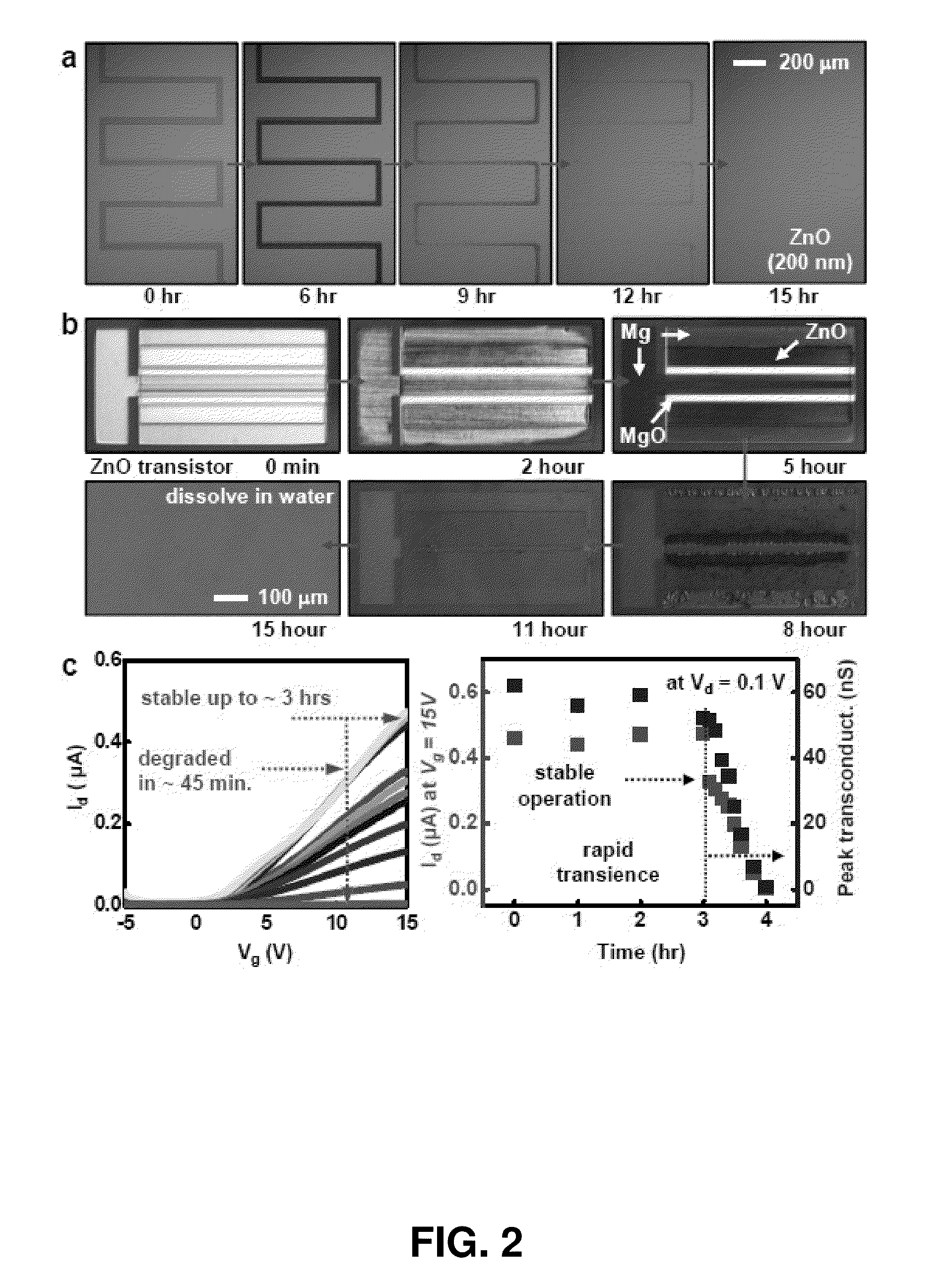

Biodegradable materials for multilayer transient printed circuit boards

ActiveUS20160050750A1Easy to removeEasy to degradeFinal product manufacturePrinted circuit dielectricsElectricityPrinted circuit board

The invention provides transient printed circuit board devices, including active and passive devices that electrically and / or physically transform upon application of at least one internal and / or external stimulus.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

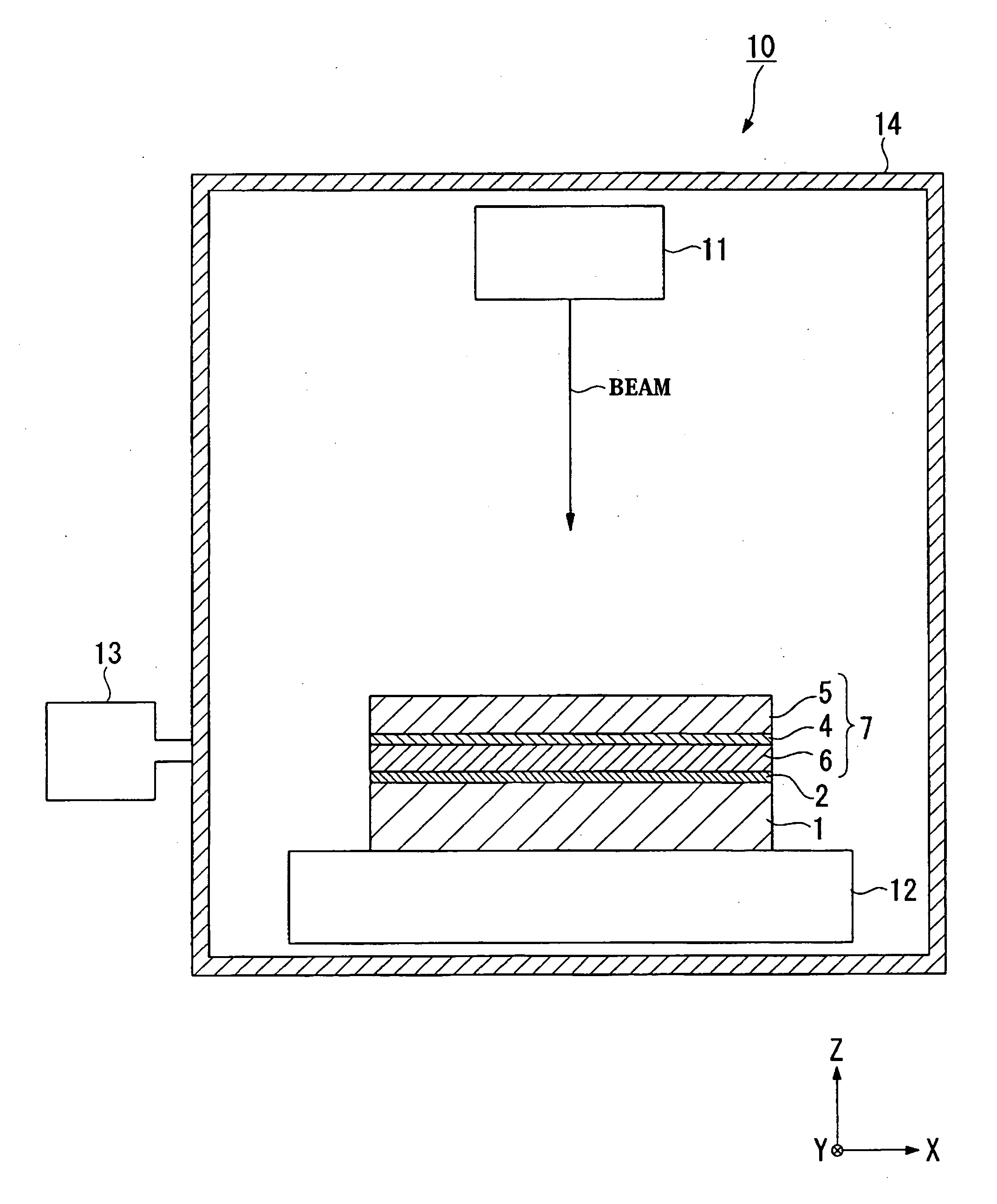

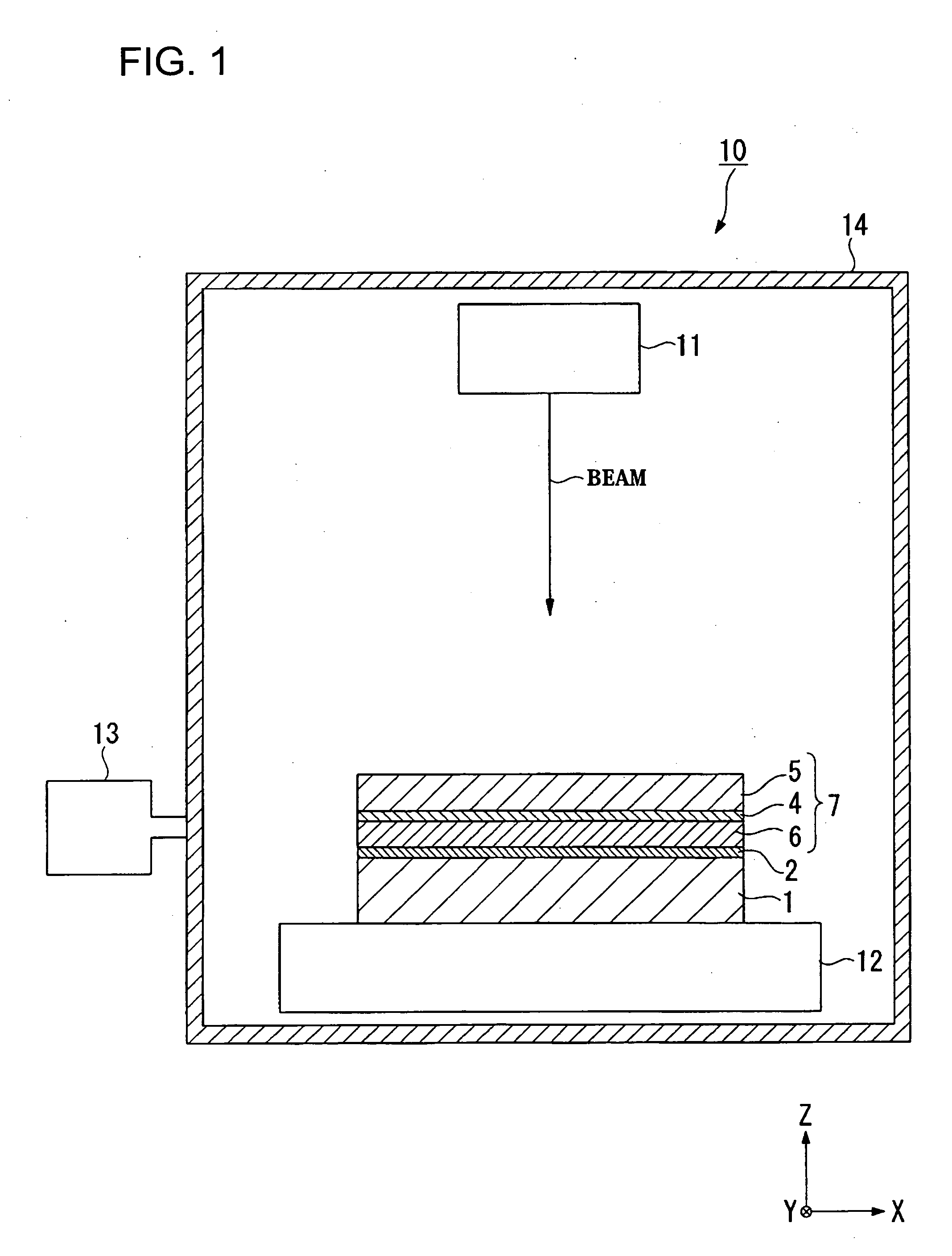

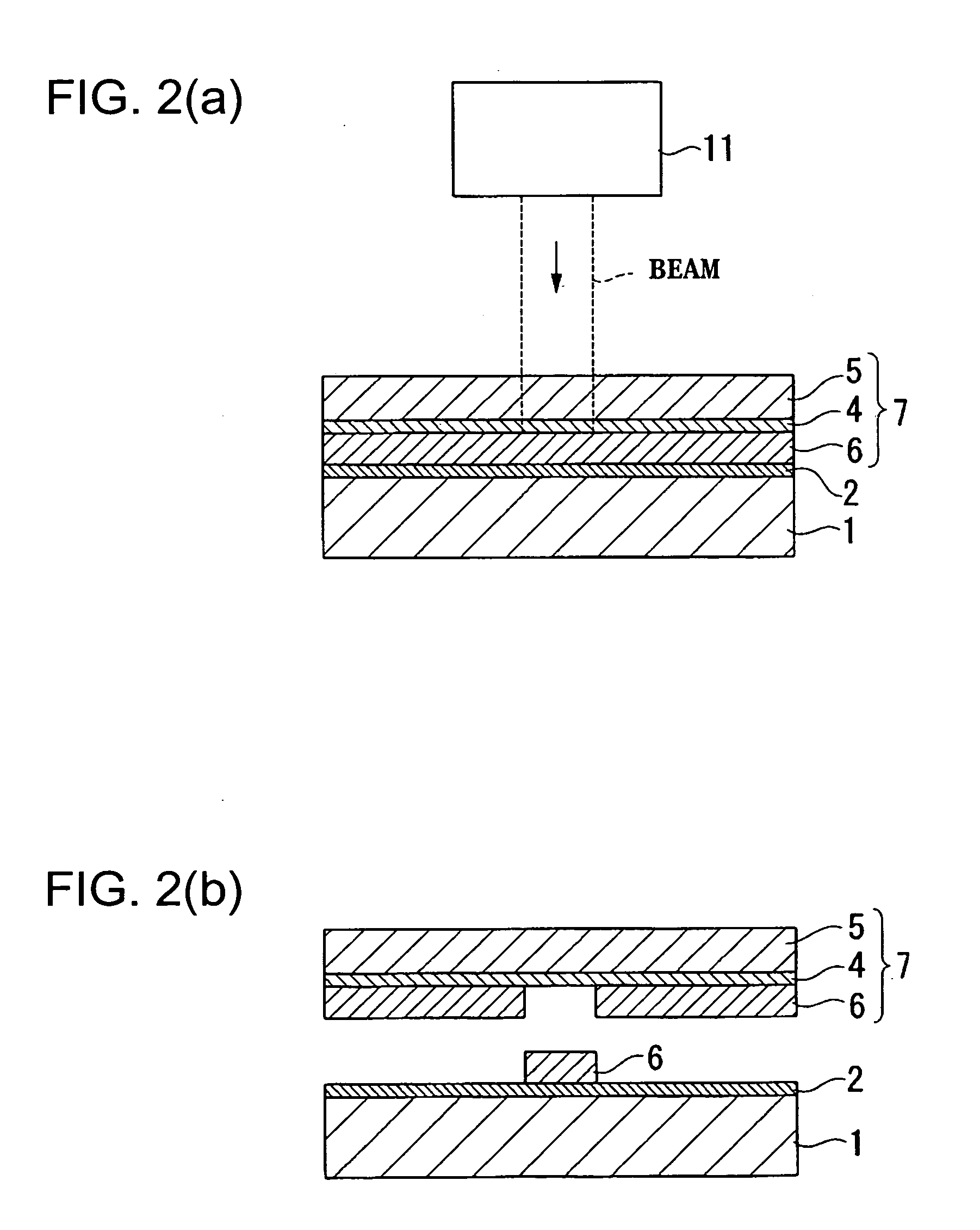

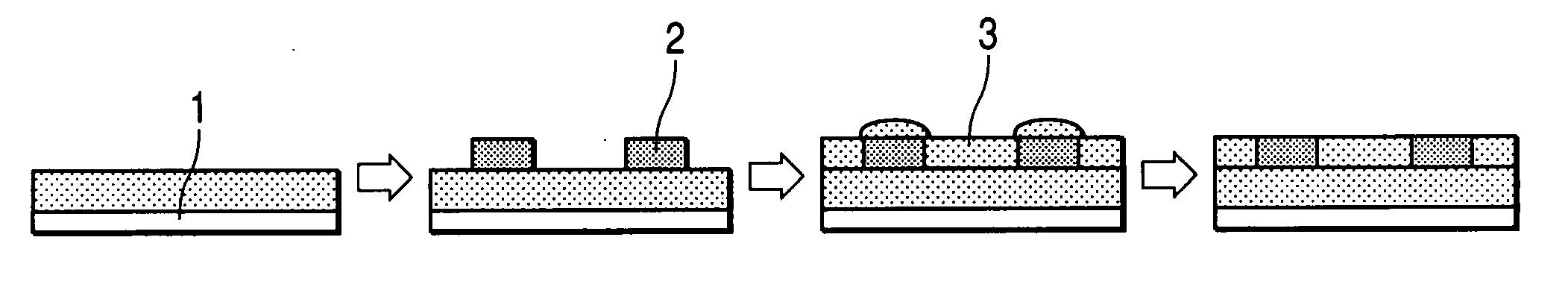

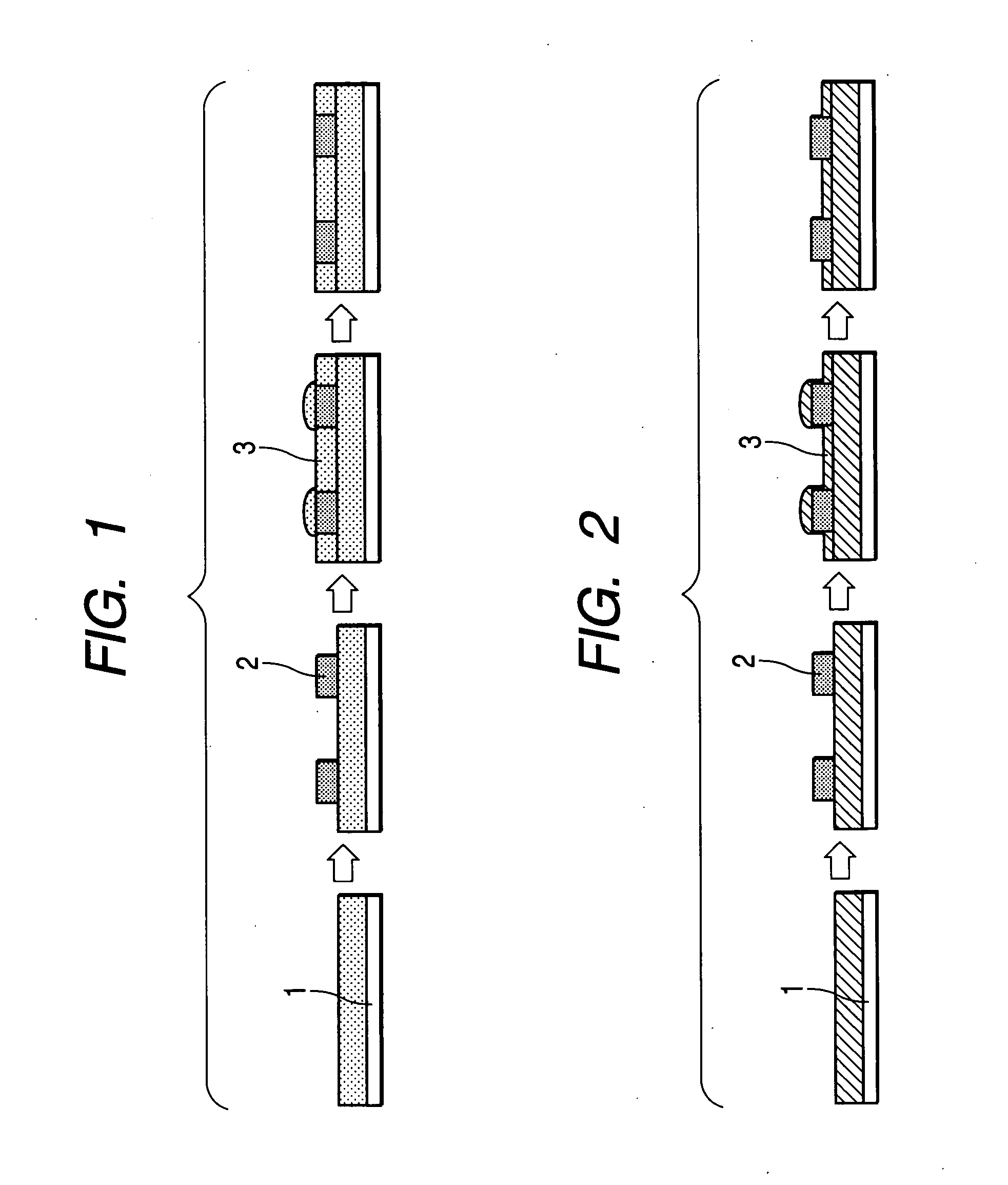

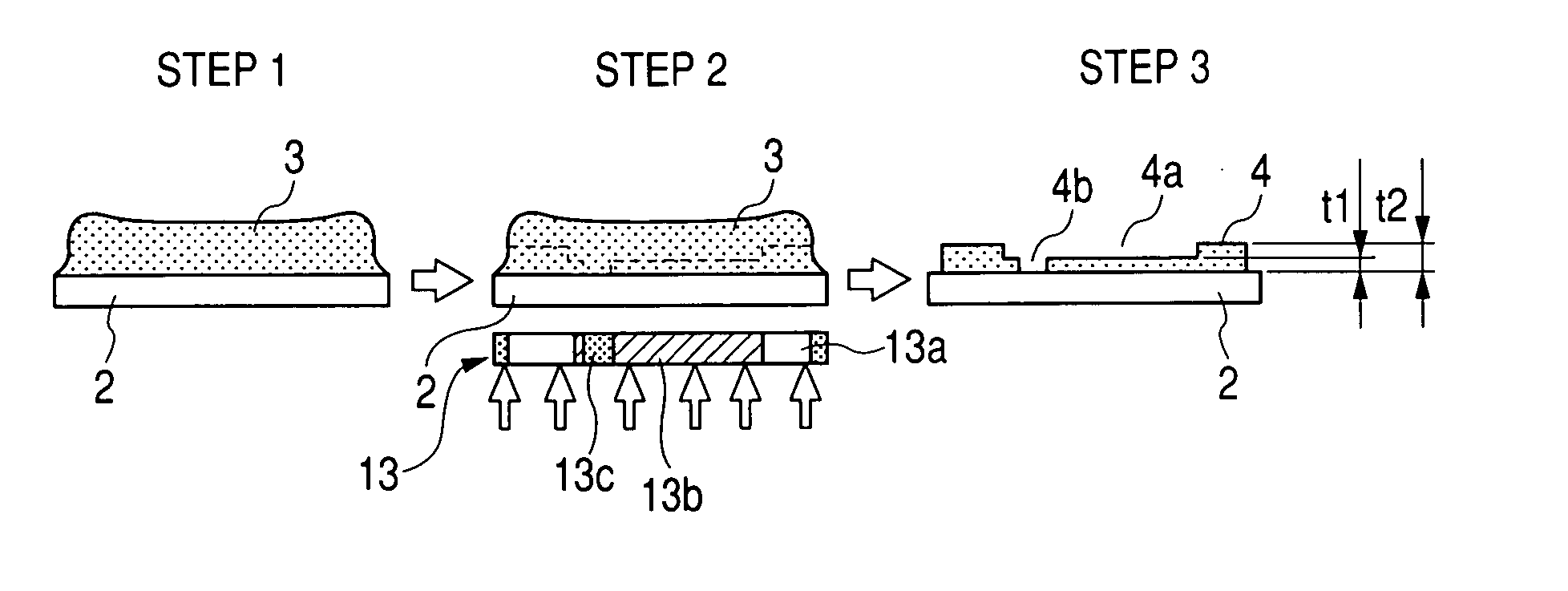

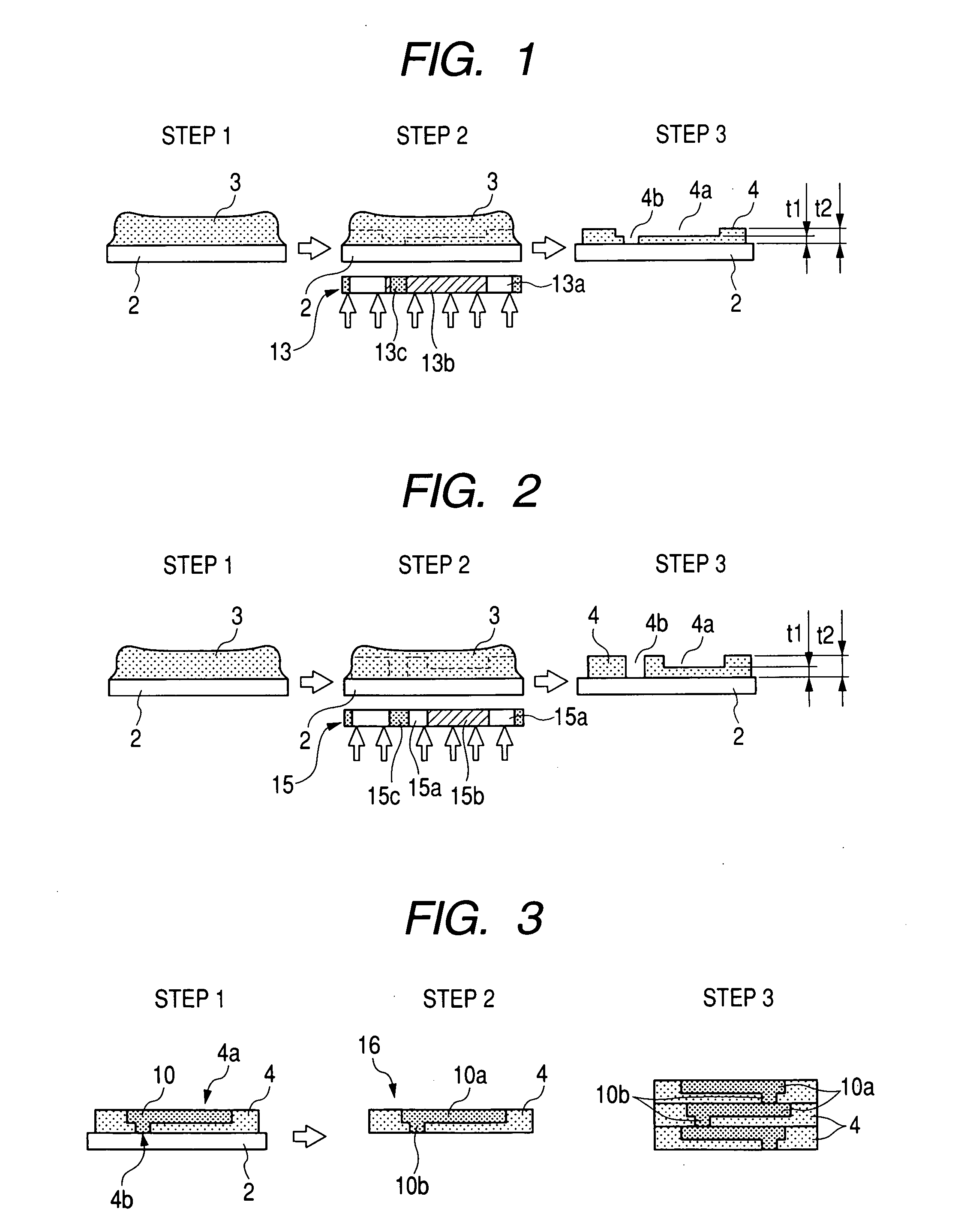

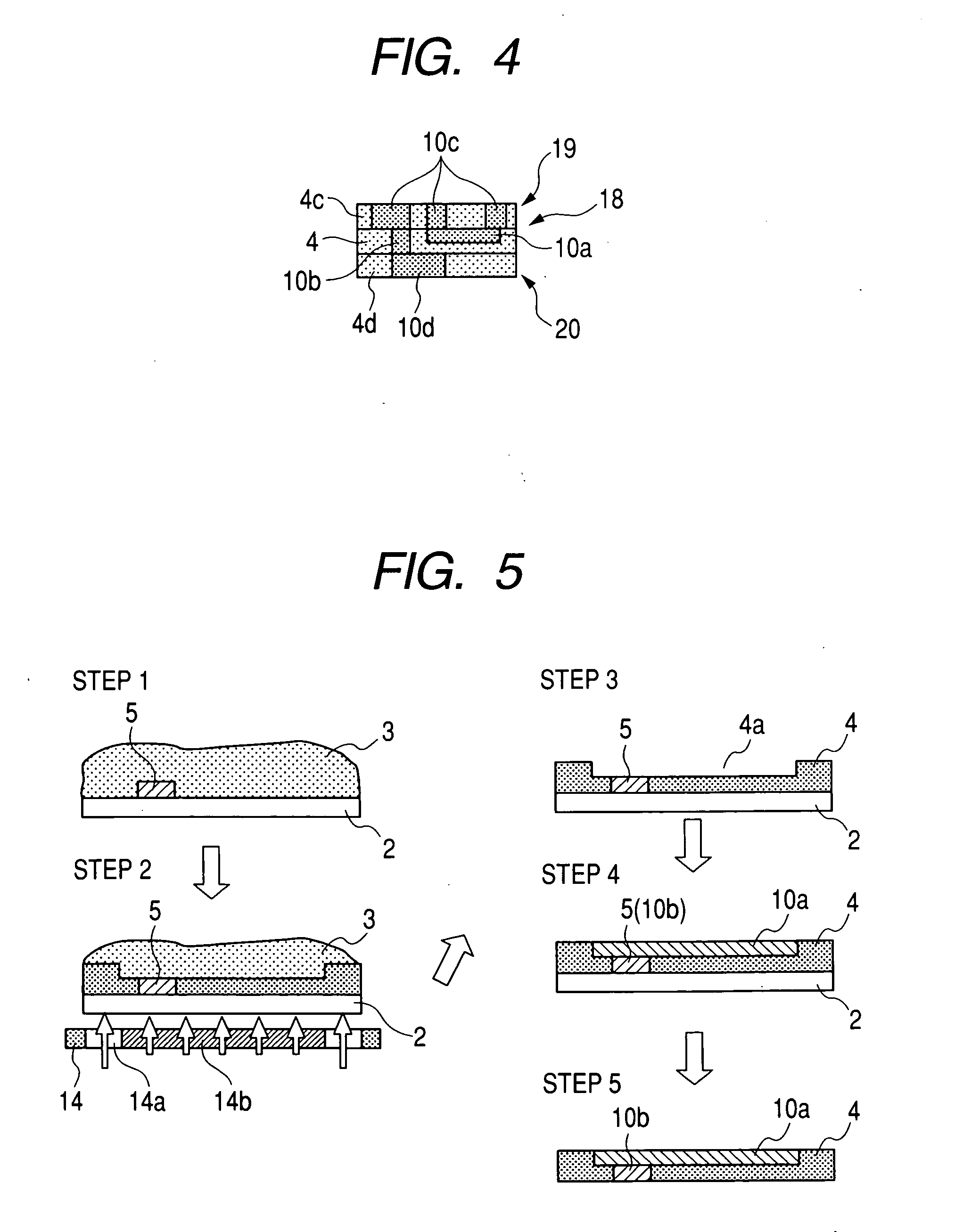

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

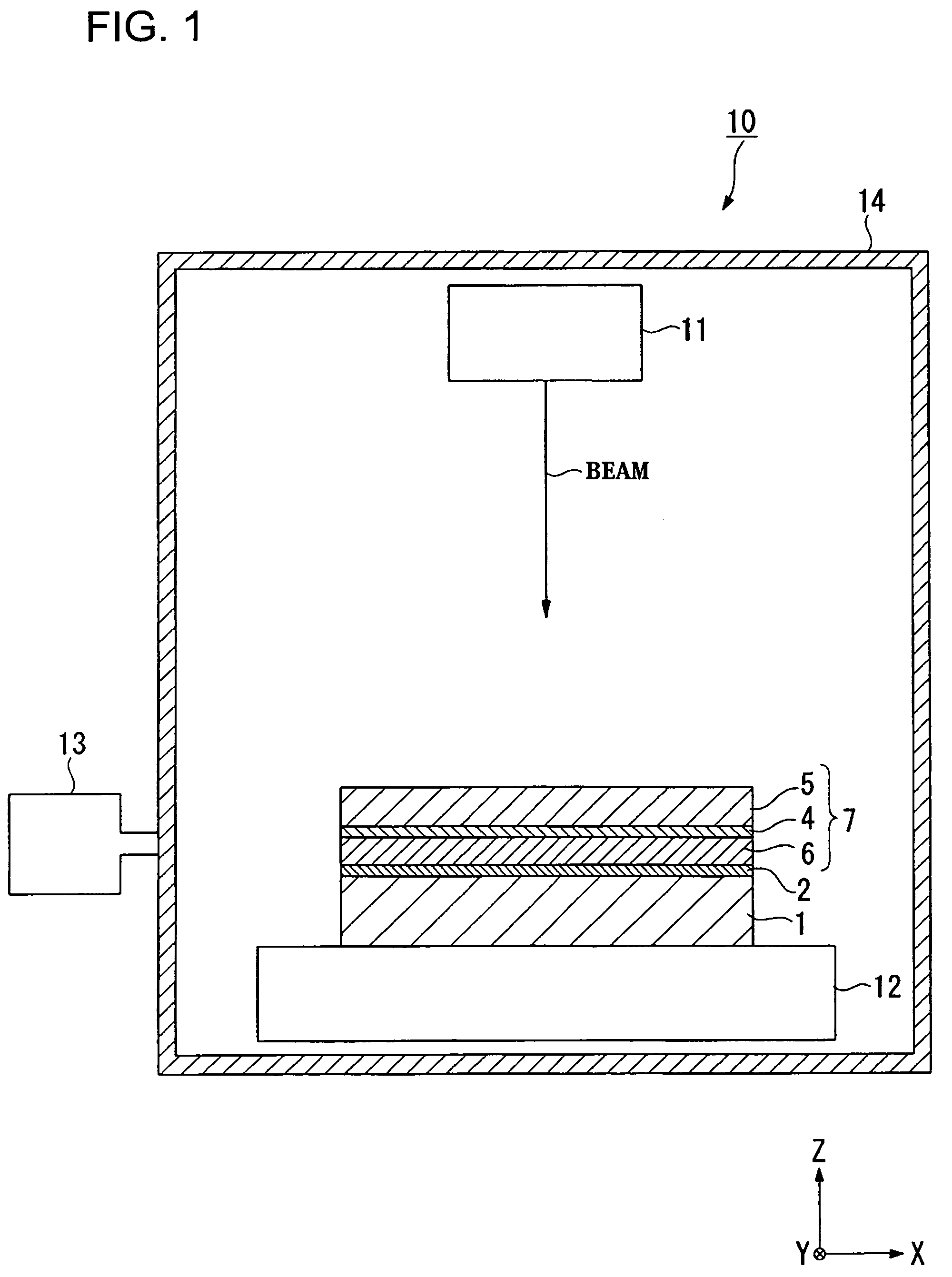

ActiveUS20050087289A1Efficiently converted into thermal energySmall diameterElectric lighting sourcesSolid-state devicesDevice materialEngineering

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Electrical, plating and catalytic uses of metal nanomaterial compositions

ActiveUS7820097B2Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

Owner:NCC NANO LLC

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS7217334B2Enhance and improve adhesionHigh quality transmissionElectric lighting sourcesSolid-state devicesEngineeringSemiconductor

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Method for fabricating micro-structures with various surface properties in multi-layer body by plasma etching

The technology is based on the anisotropic plasma etching of organic polymer sheets partially protected by a metallic mask. The originality of the process is to pattern the surface properties by the same physical means as the one used for the three dimensional fabrication and simultaneously to this fabrication. Surface properties means, but are not limited to hydrophobicity, hydrophilicity, conductivity, reflectability, rugosity and more precisely the chemical and / or physical state of the surface. It is also possible to generate the desired fonctionalities, for instance carboxylic acid, ester, ether, amid or imid, during the etching process. The patterning of the different properties may be achieved by two different techniques that may be used separately or simultaneously.

Owner:DIAGNOSWISS

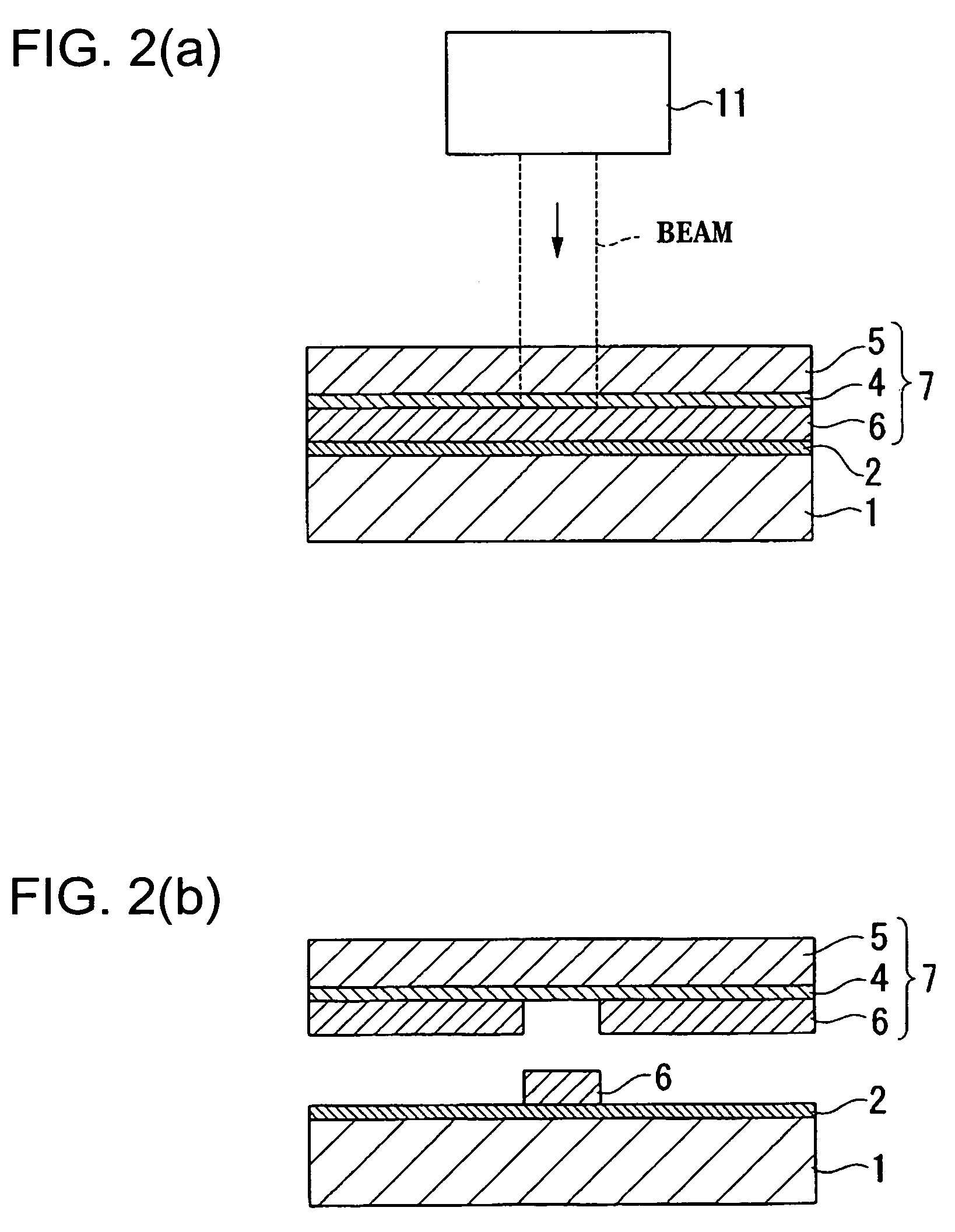

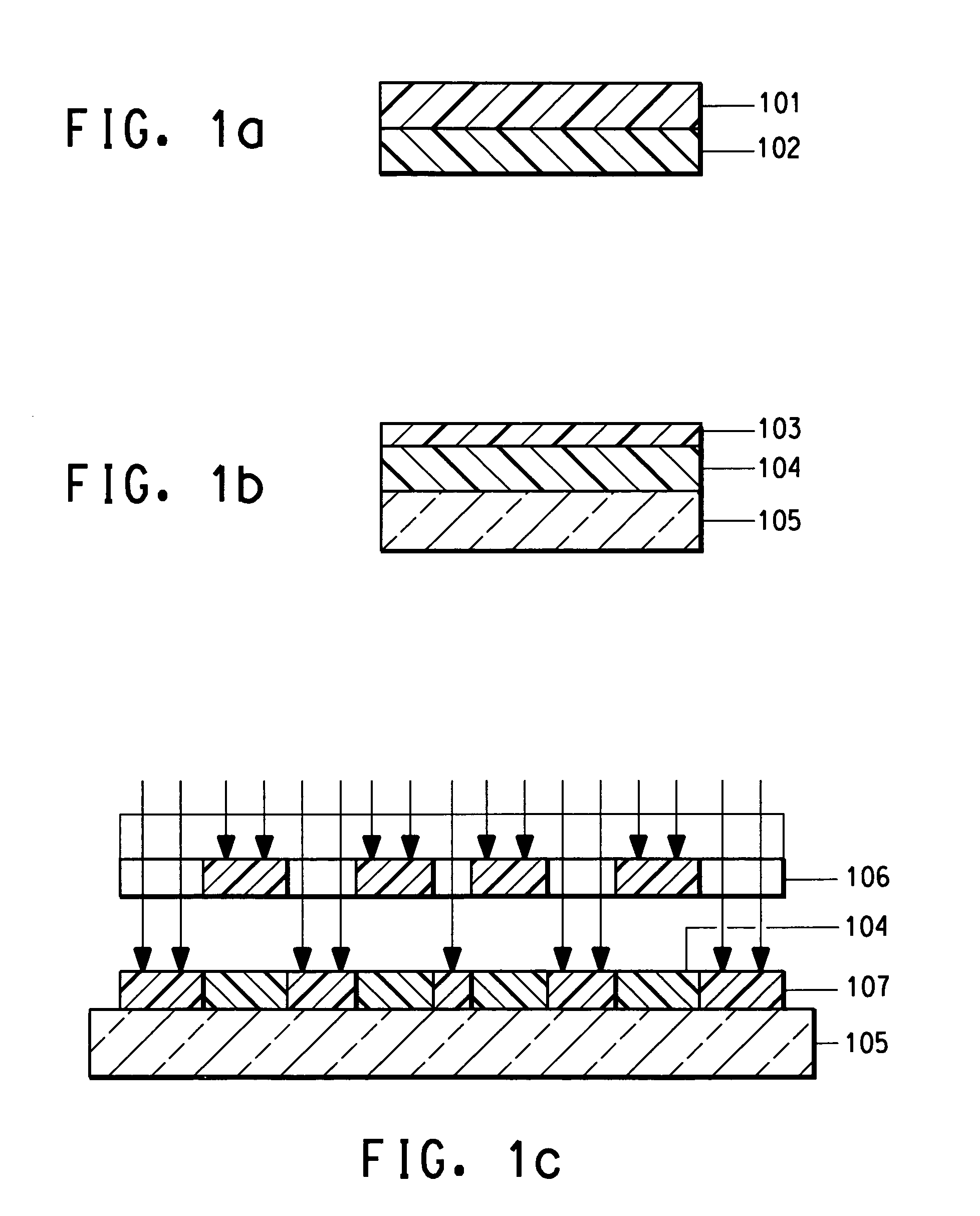

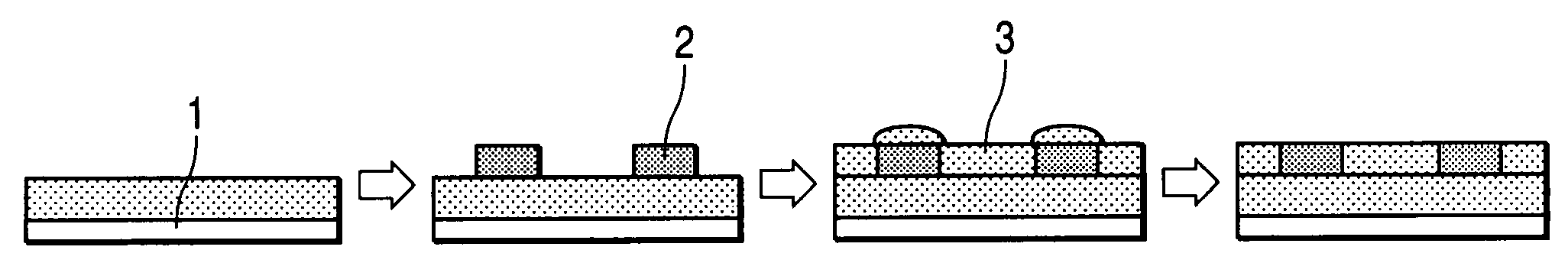

Process for thick film circuit patterning

InactiveUS7052824B2Photosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitive polymerEngineering

A process for patterning thick film electrically functional patterns using a photosensitive polymer layer. A tacky photosensitive layer is applied onto a substrate surface. The photosensitive layer is imaged with a pattern using actinic radiation, the exposed areas of the photosensitive layer become hardened and non-tacky. A subsequent application of a thick film composition sheet will cause the thick film to adhere to the remaining tacky areas. Upon peeling the sheet, a thick film print pattern will be produced. This step is followed by a processing profile prescribed by the thick film composition used which results in a pattern having electrically functional properties. The invention also extends to a process wherein a thick film composition is recovered from a used sheet.

Owner:EI DU PONT DE NEMOURS & CO

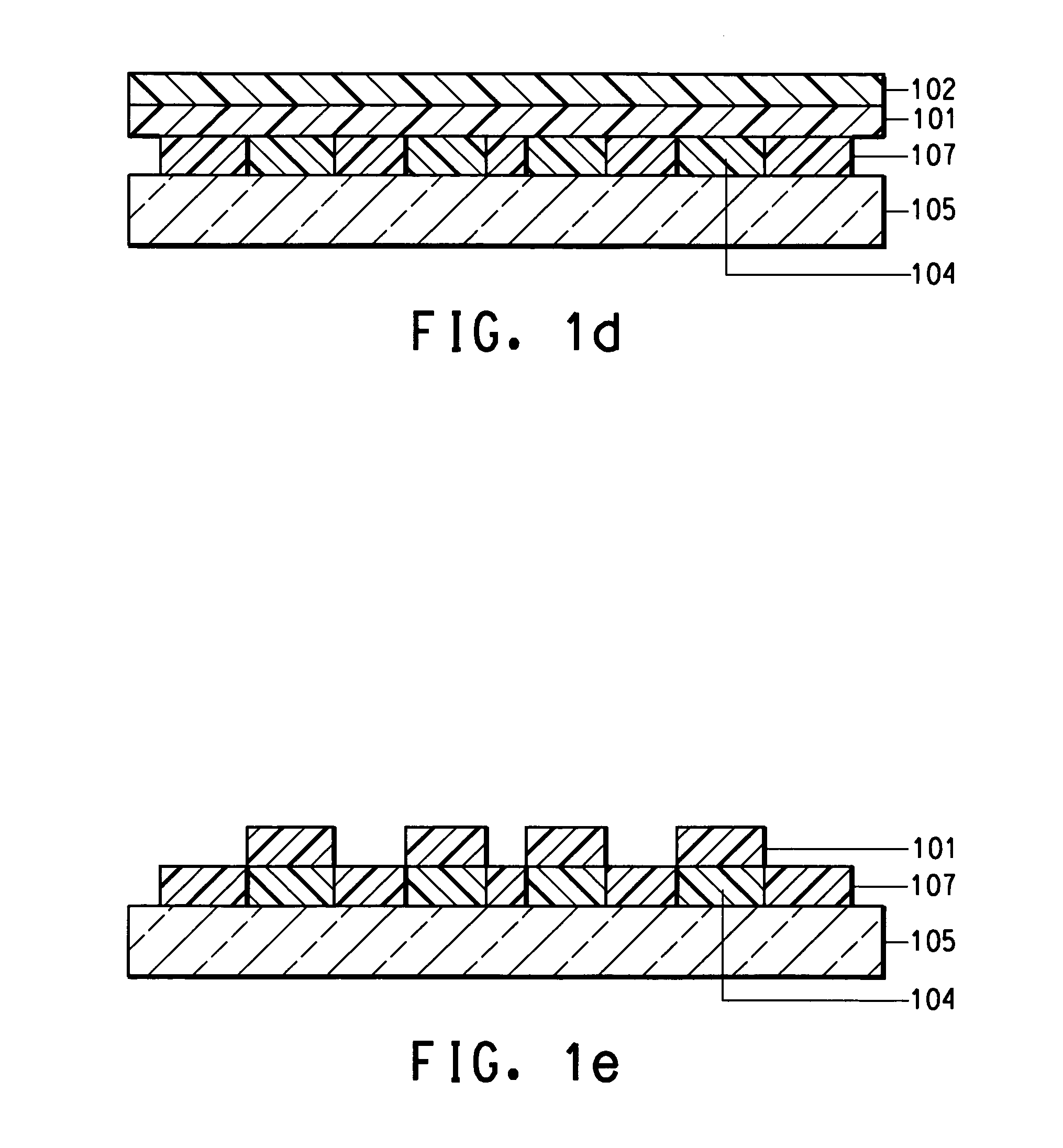

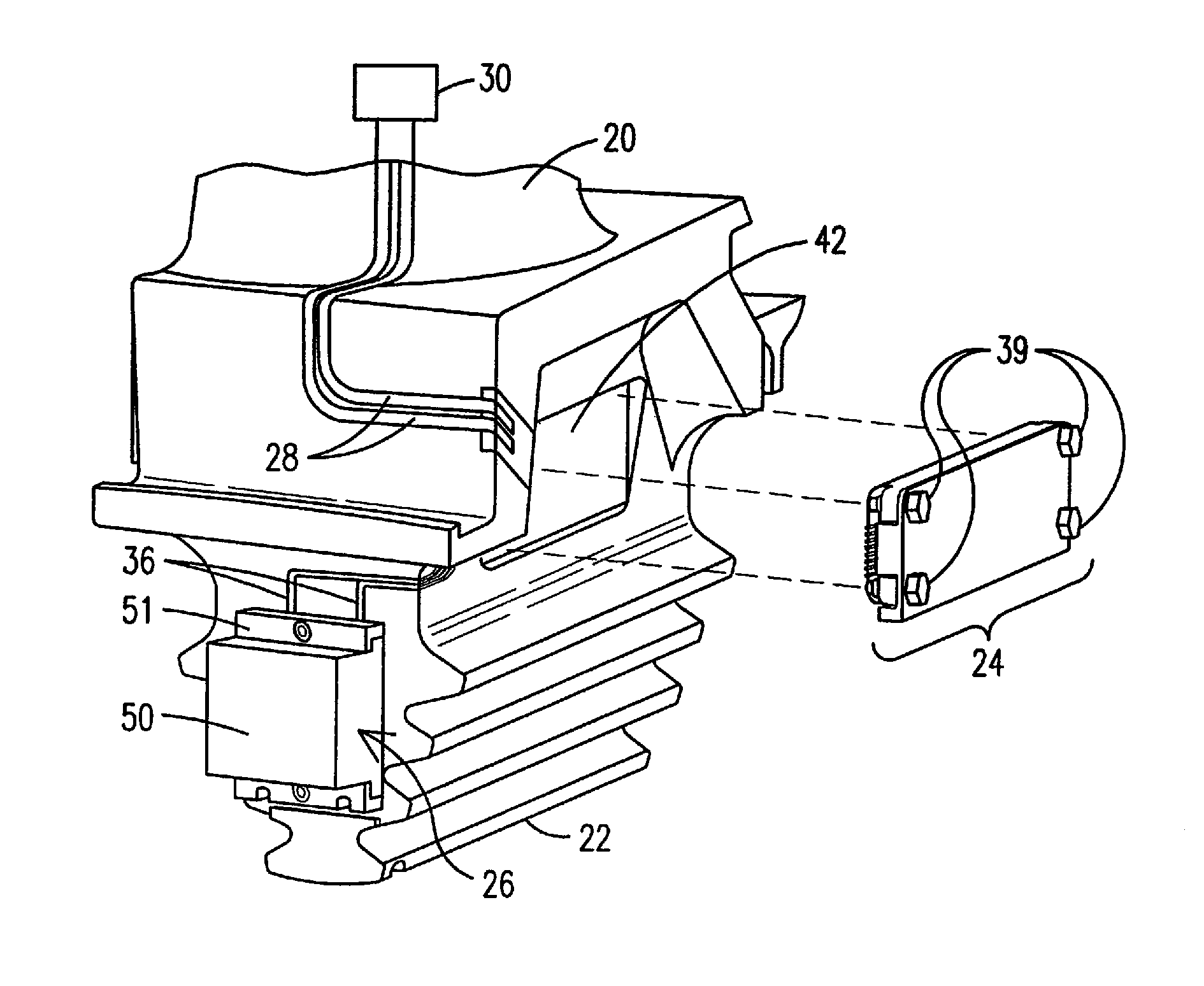

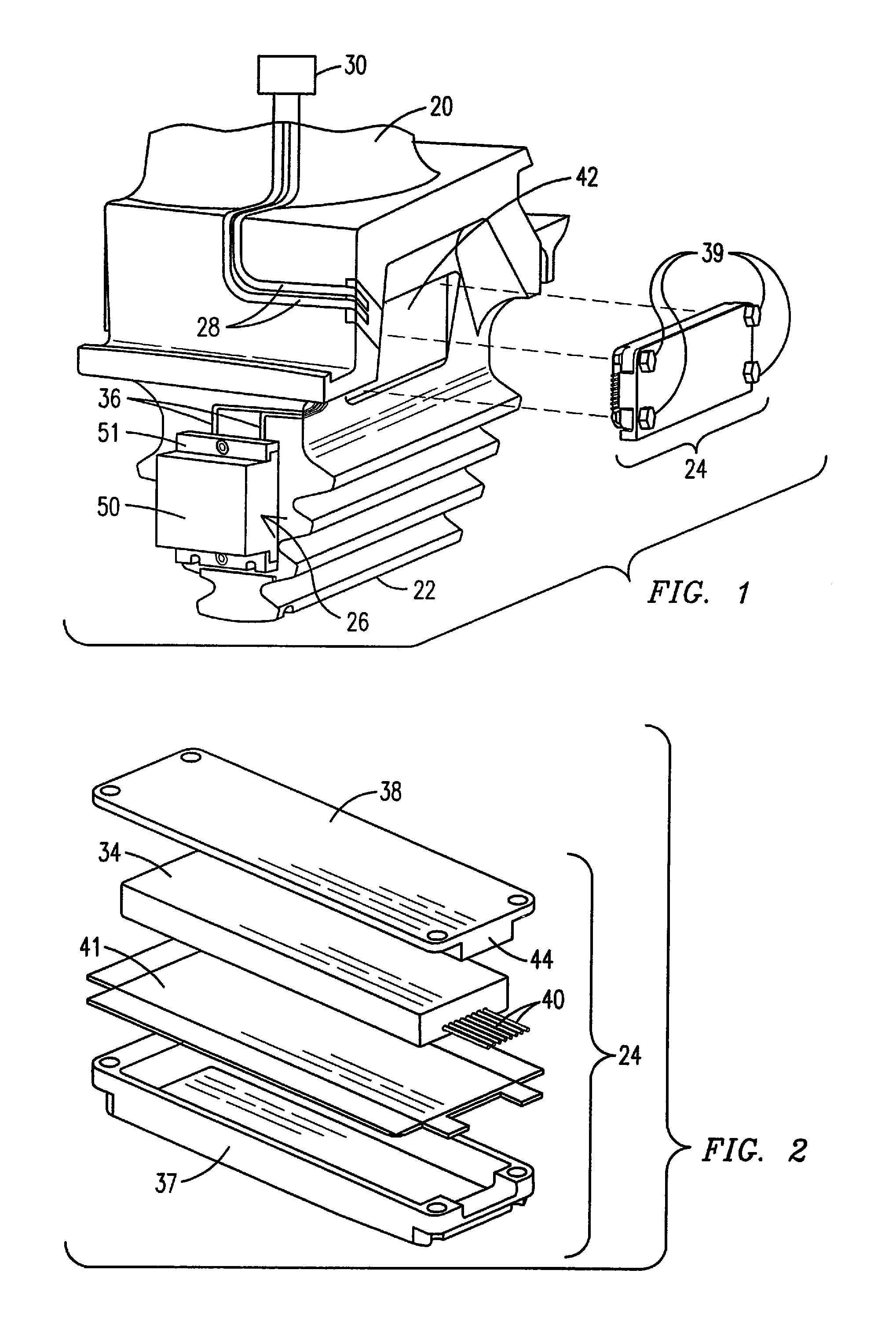

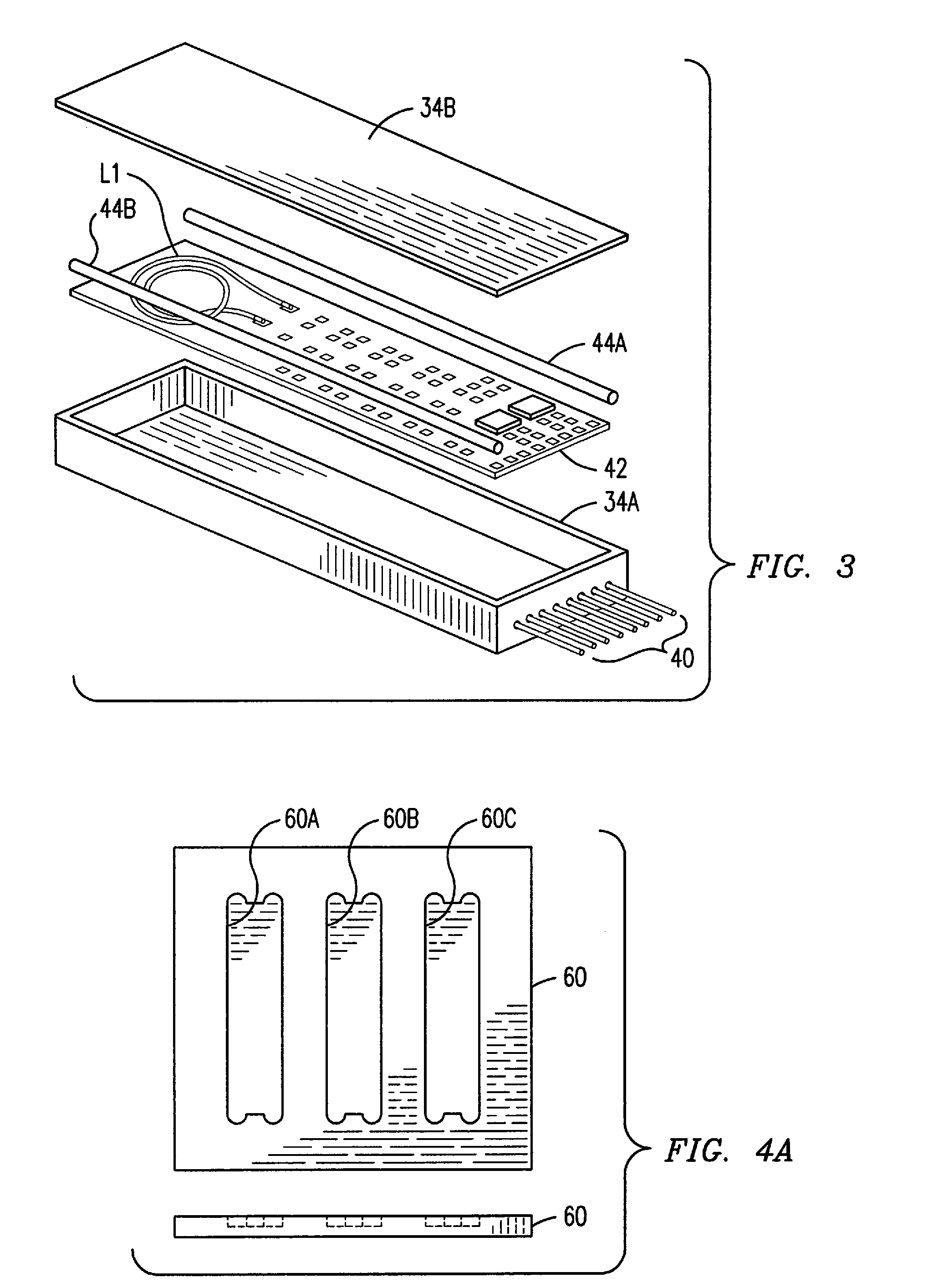

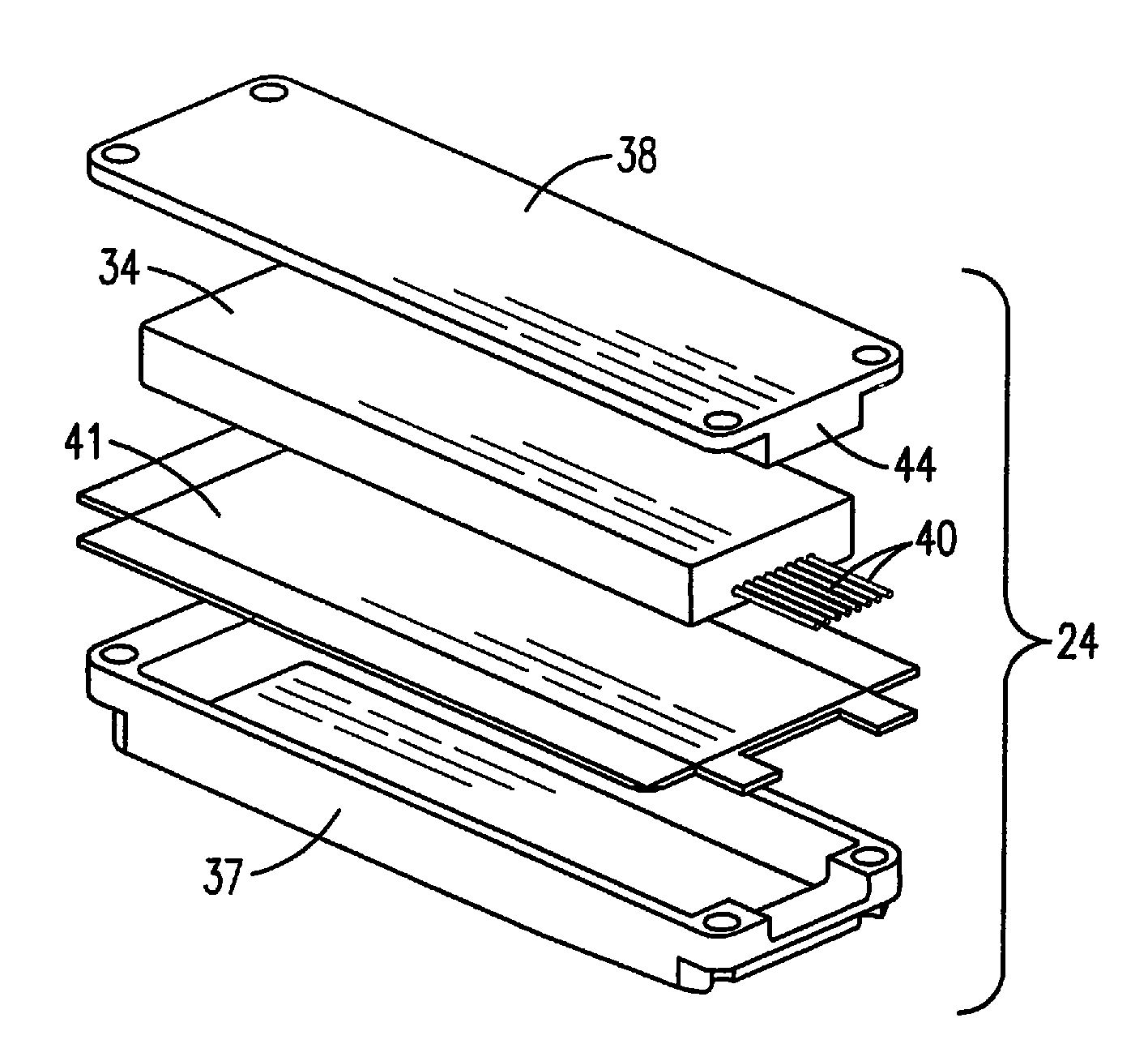

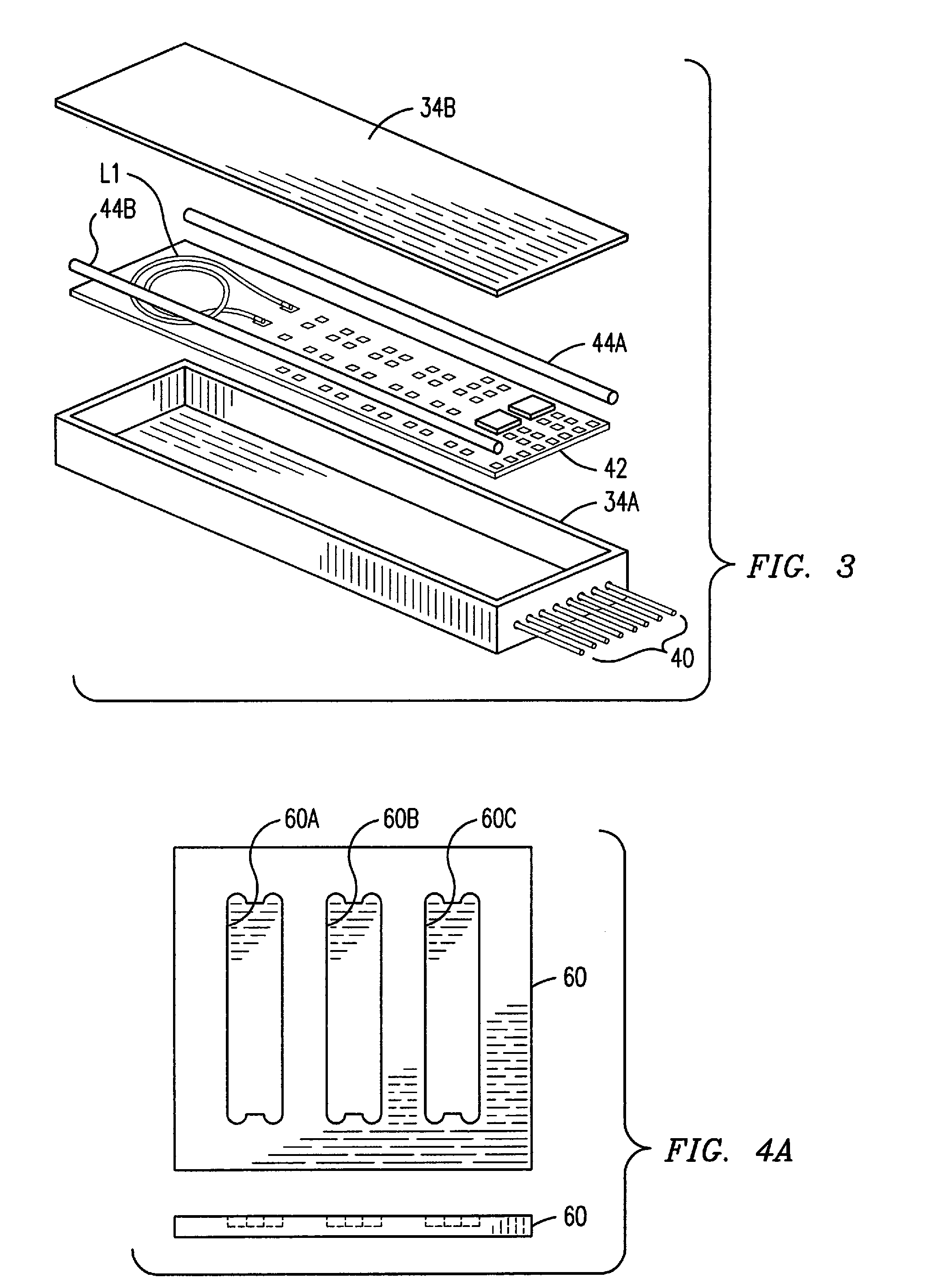

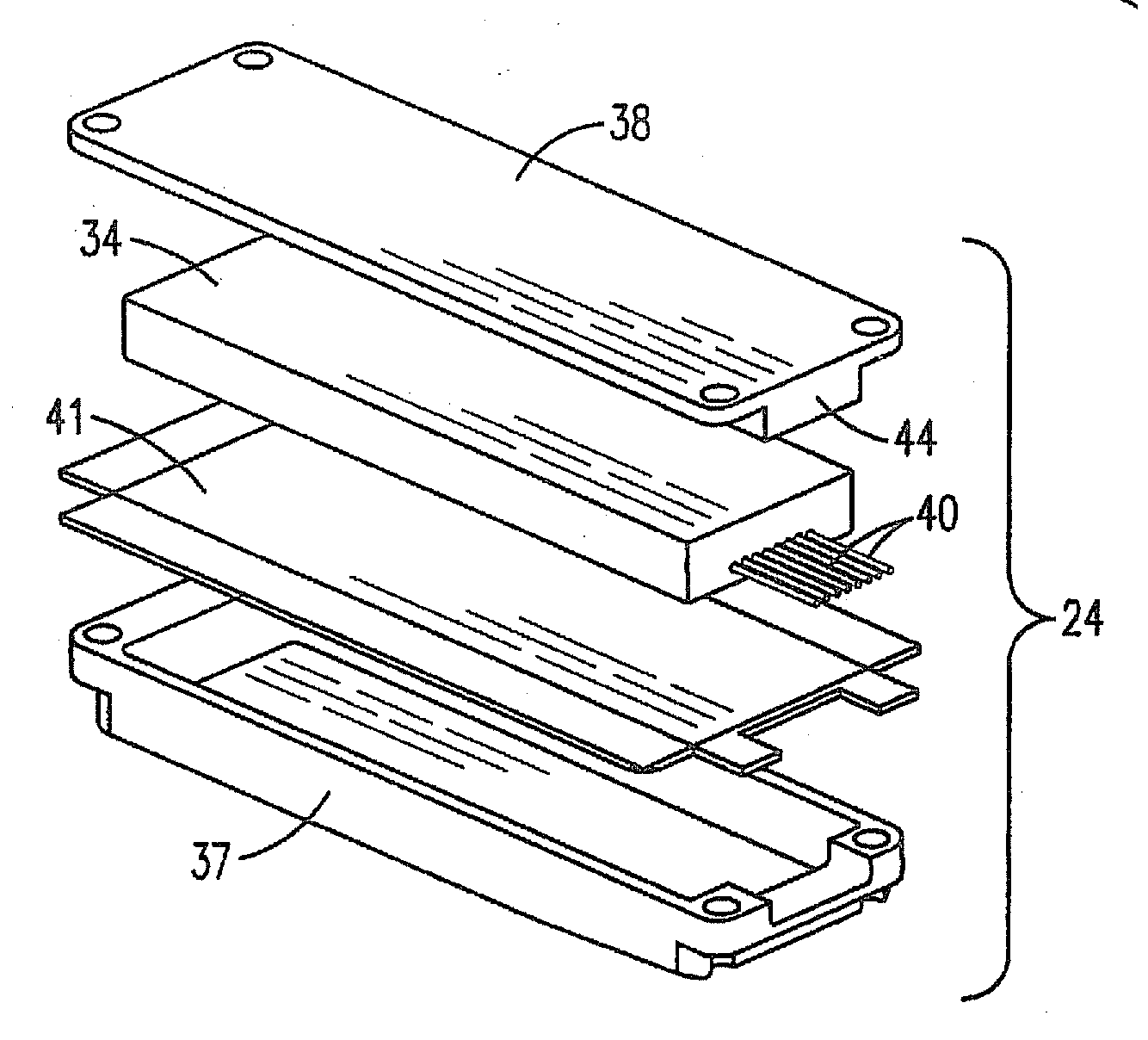

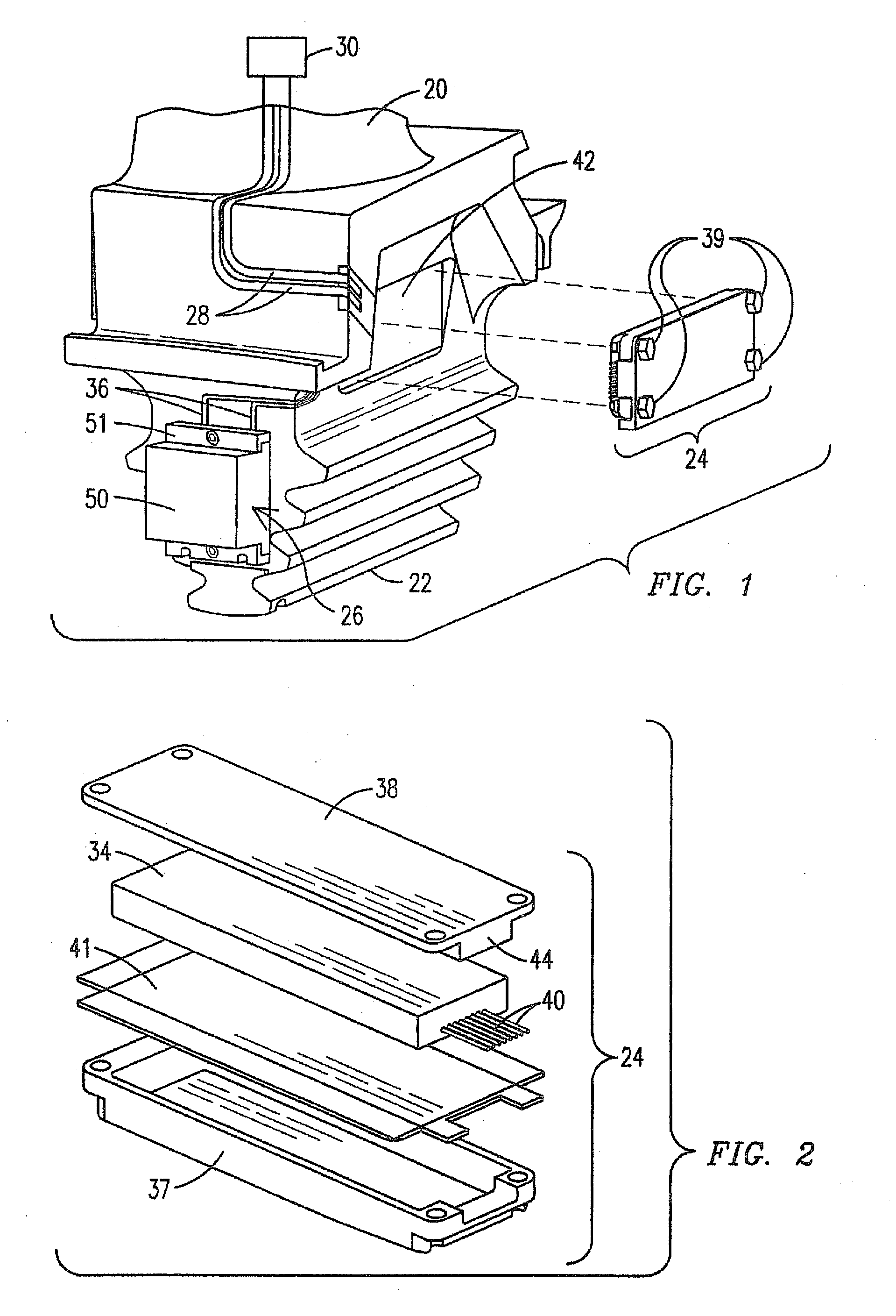

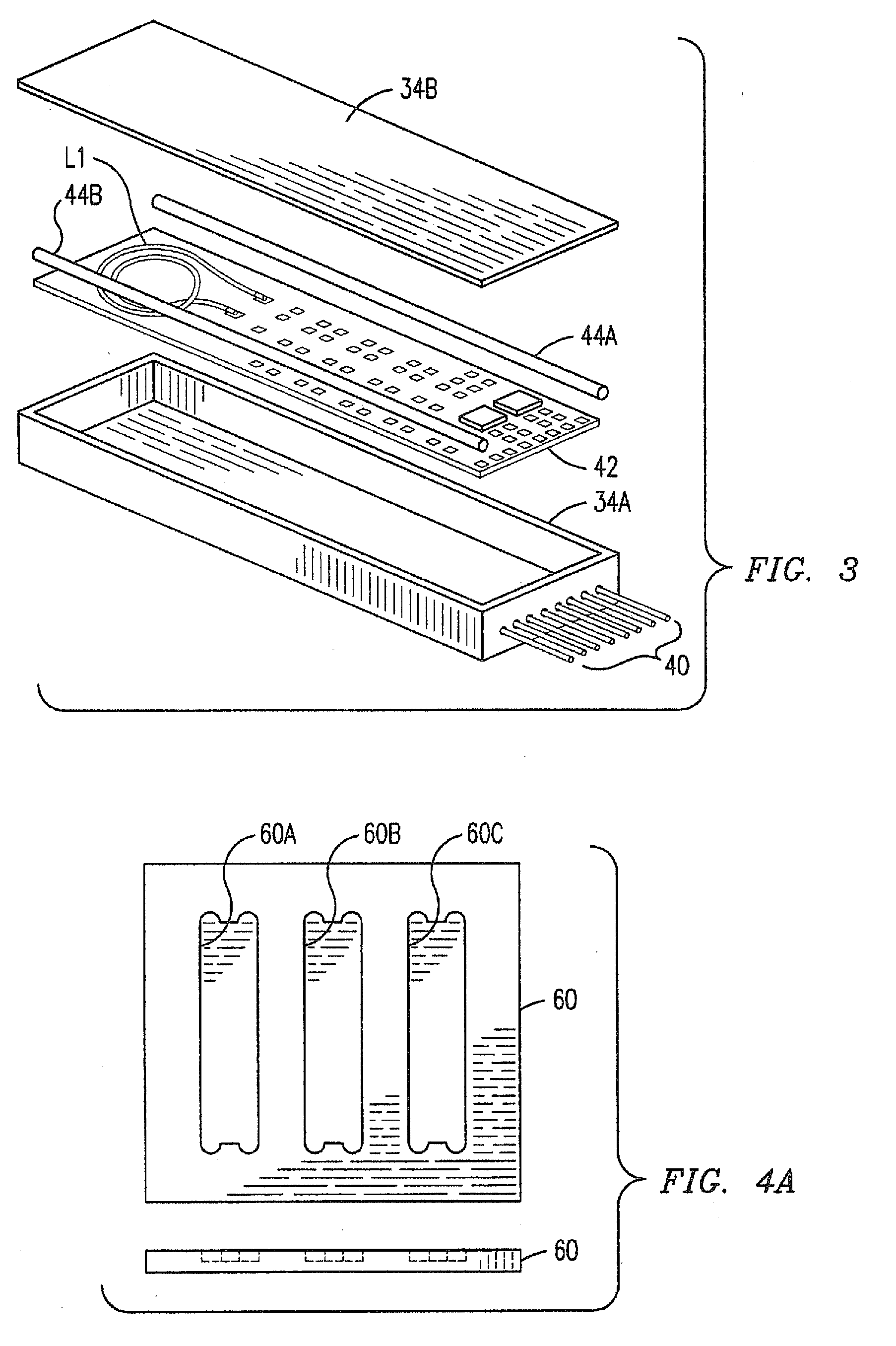

Wireless telemetry electronic circuit board for high temperature environments

InactiveUS8023269B2Semiconductor/solid-state device detailsSolid-state devicesActive componentEngineering

A circuit assembly (34) resistant to high-temperature and high g centrifugal force is disclosed. A printed circuit board (42) is first fabricated from alumina and has conductive traces of said circuit formed thereon by the use of a thick film gold paste. Active and passive components of the circuit assembly are attached to the printed circuit board by means of gold powder diffused under high temperature. Gold wire is used for bonding between the circuit traces and the active components in order to complete the circuit assembly (34). Also, a method for manufacturing a circuit assembly resistant to elevated temperature is disclosed.

Owner:CREE FAYETTEVILLE +1

Process for thick film circuit patterning

InactiveUS20030211406A1Photosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitive polymerSubstrate surface

A process for patterning thick film electrically functional patterns using a photosensitive polymer layer. A tacky photosensitive layer is applied onto a substrate surface. The photosensitive layer is imaged with a pattern using actinic radiation, the exposed areas of the photosensitive layer become hardened and non-tacky. A subsequent application of a thick film composition sheet will cause the thick film to adhere to the remaining tacky areas. Upon peeling the sheet, a thick film print pattern will be produced. This step is followed by a processing profile prescribed by the thick film composition used which results in a pattern having electrically functional properties. The invention also extends to a process wherein a thick film composition is recovered from a used sheet.

Owner:EI DU PONT DE NEMOURS & CO

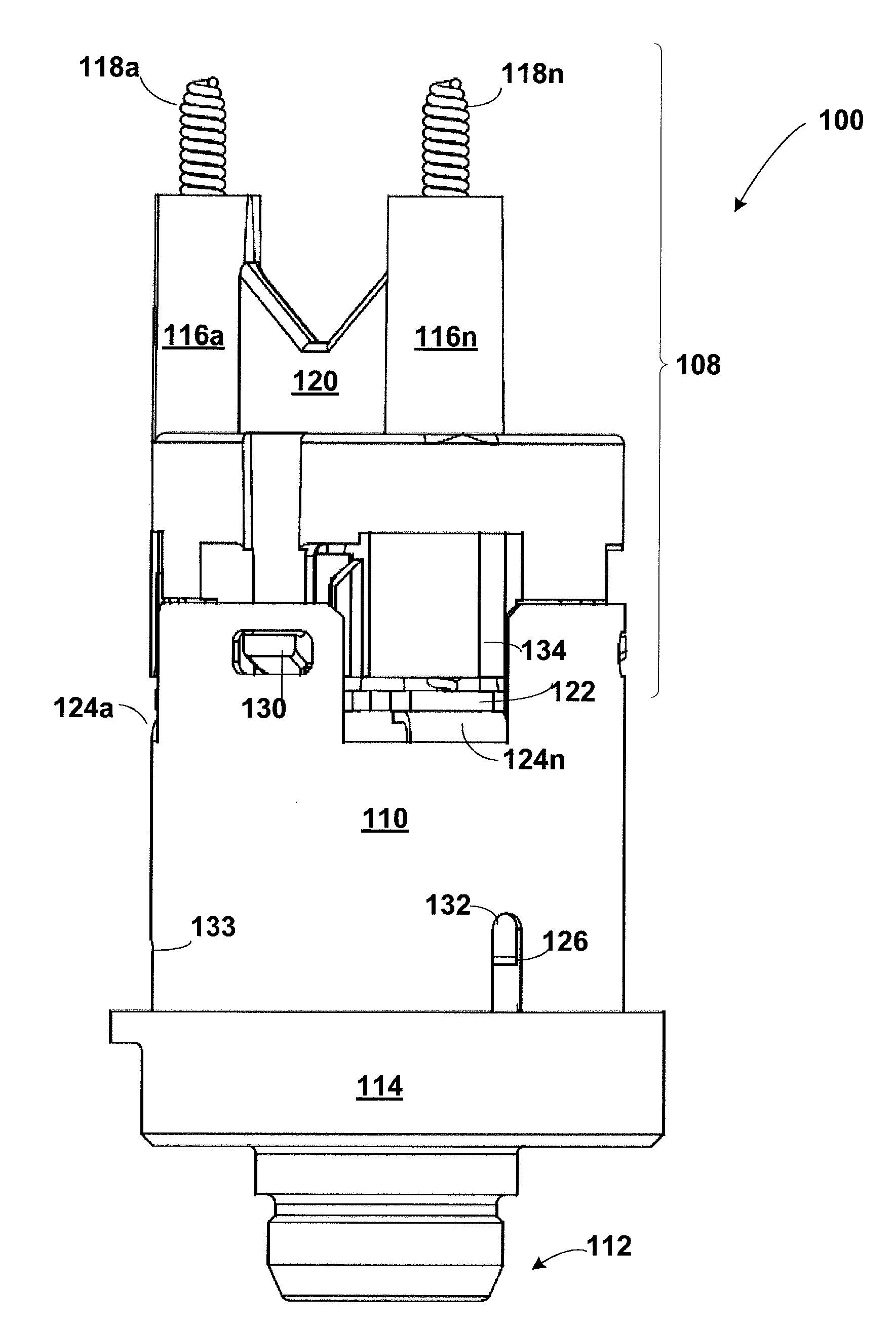

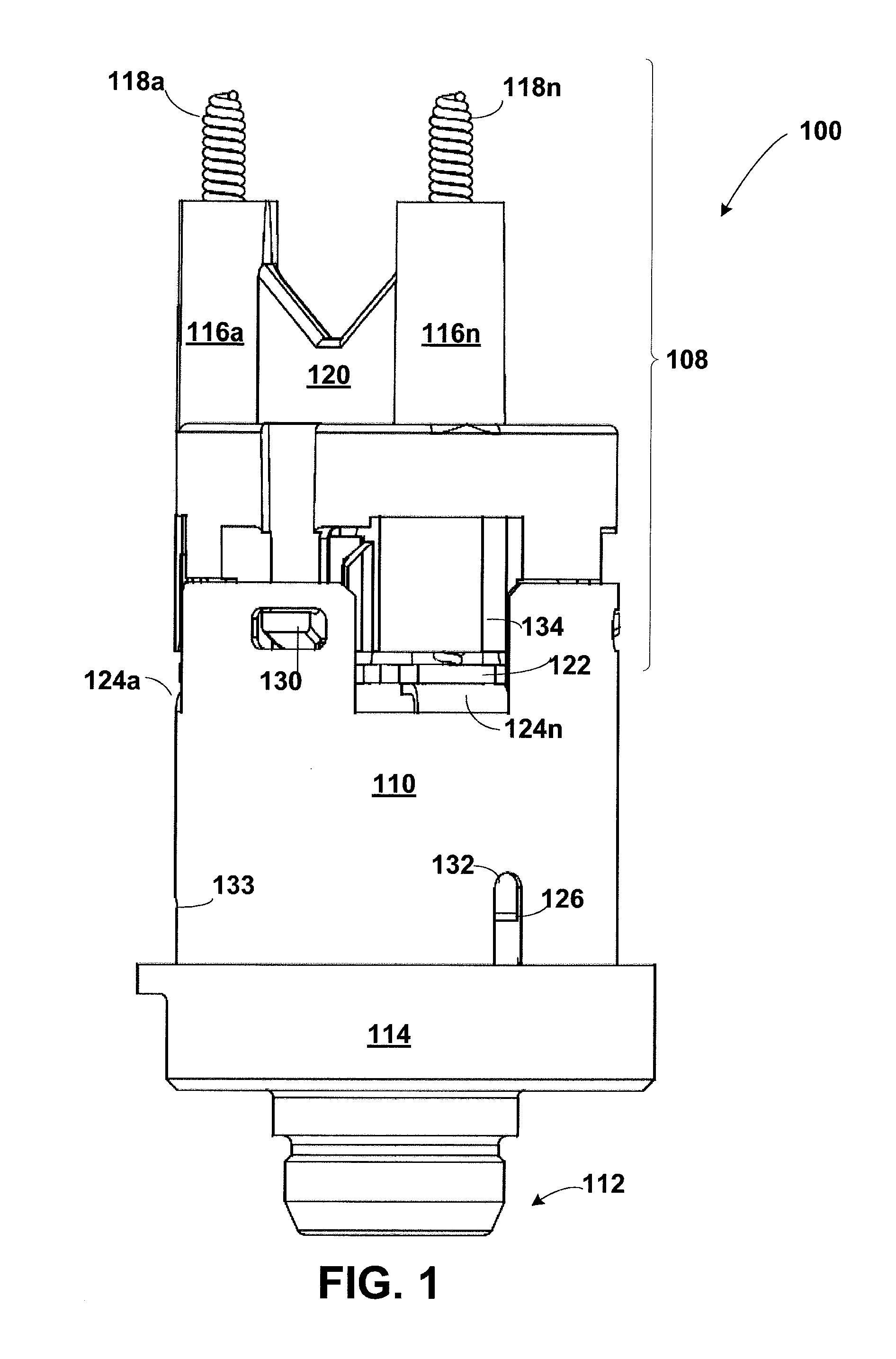

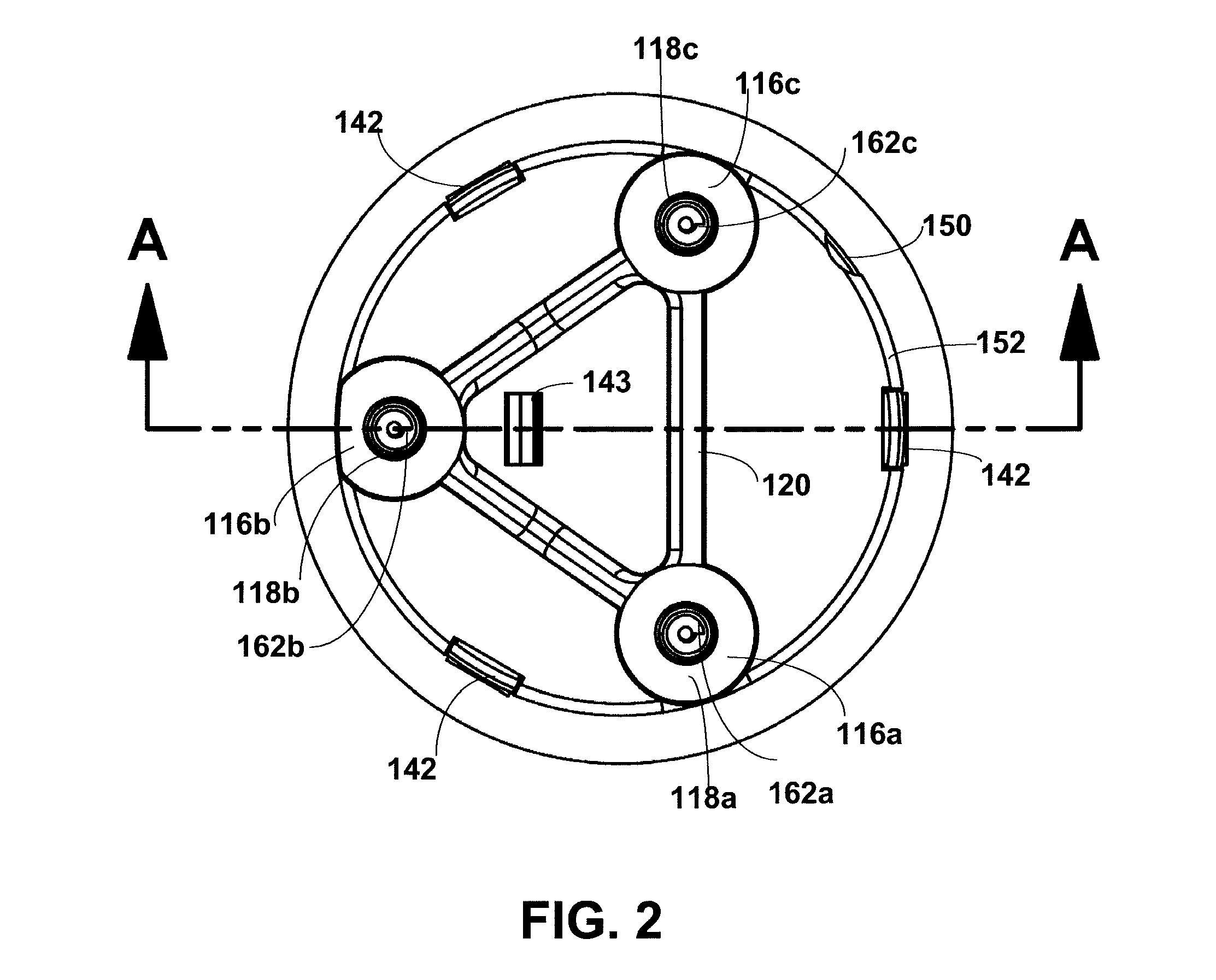

Pressure sensor

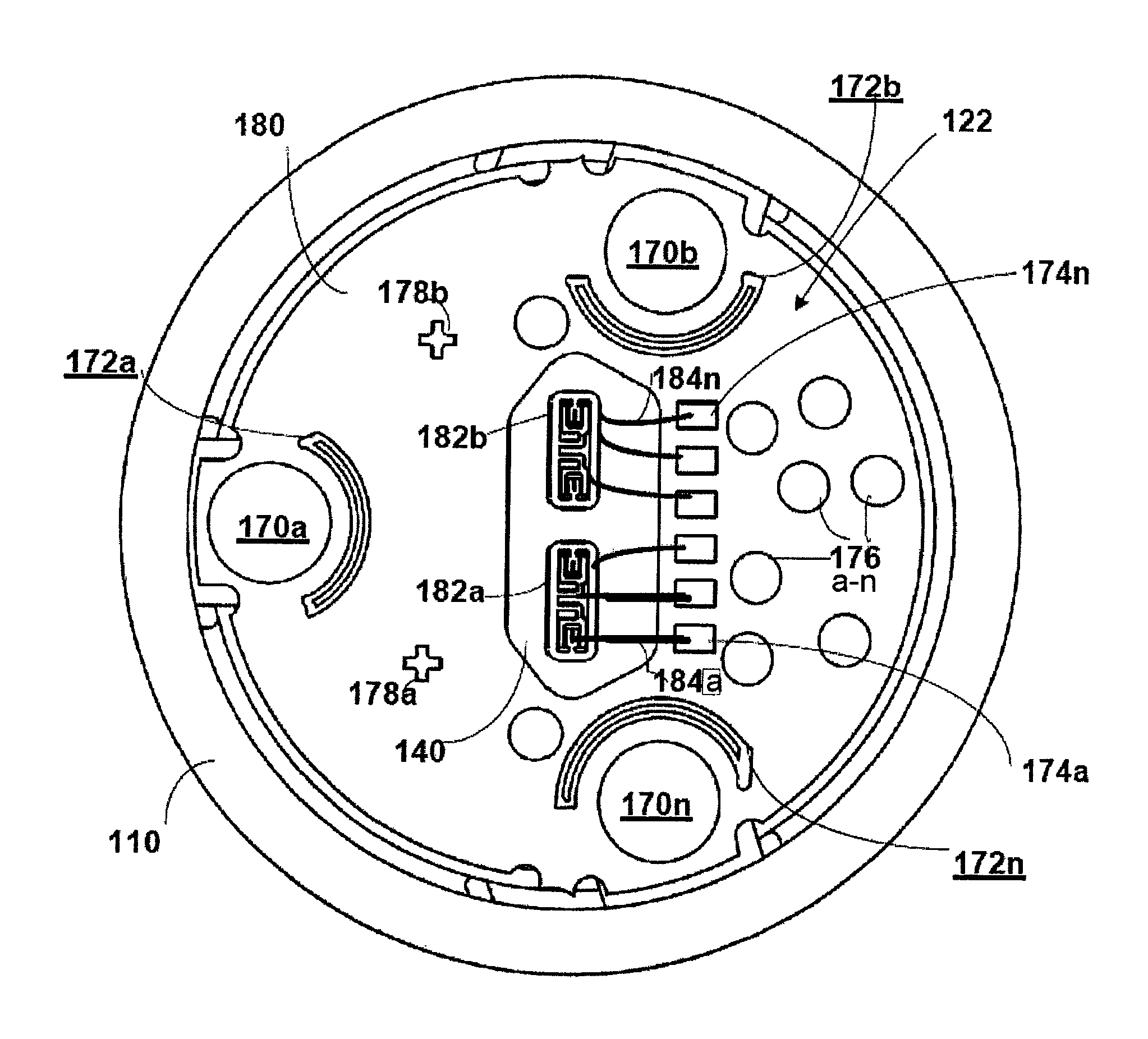

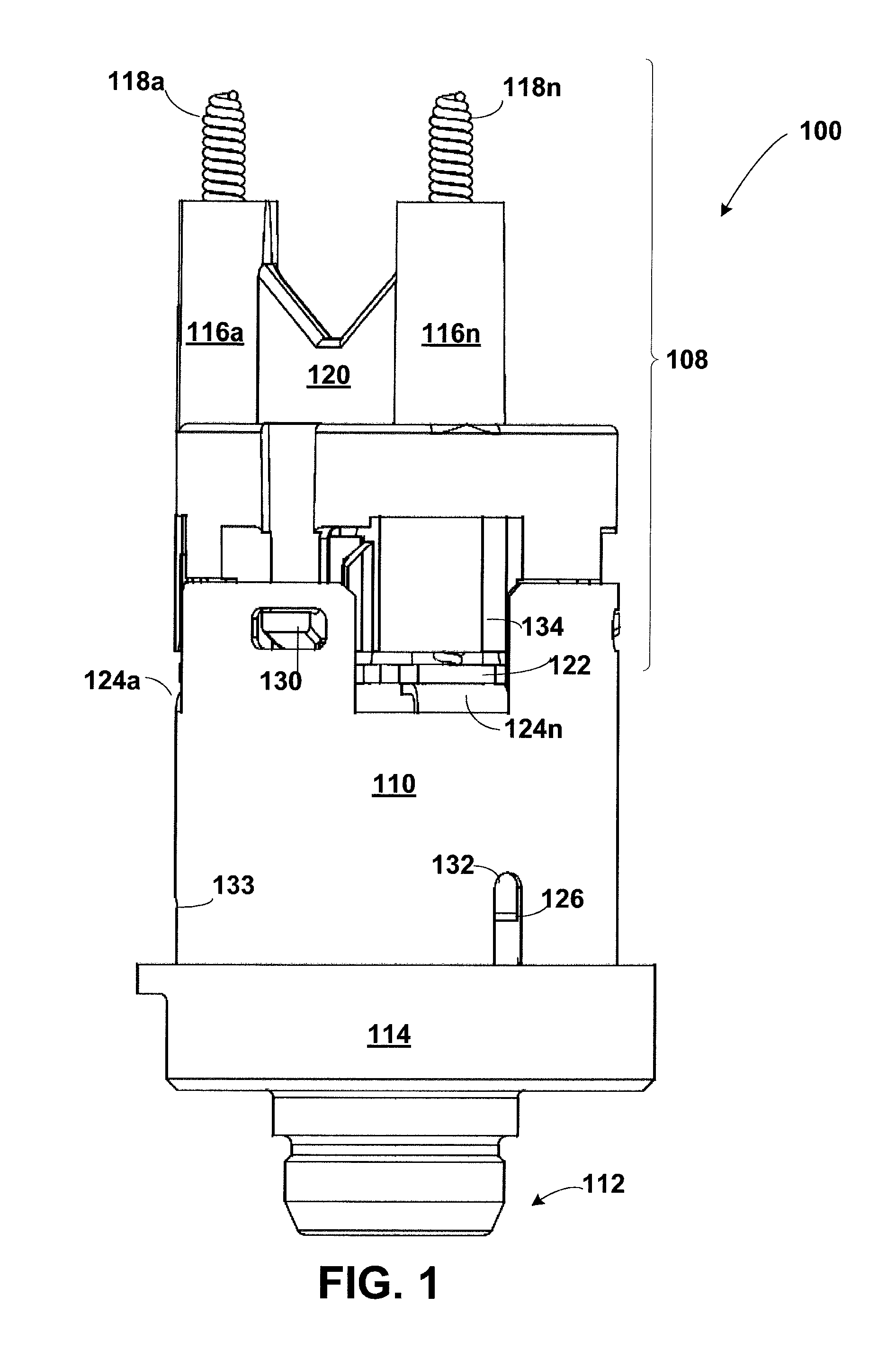

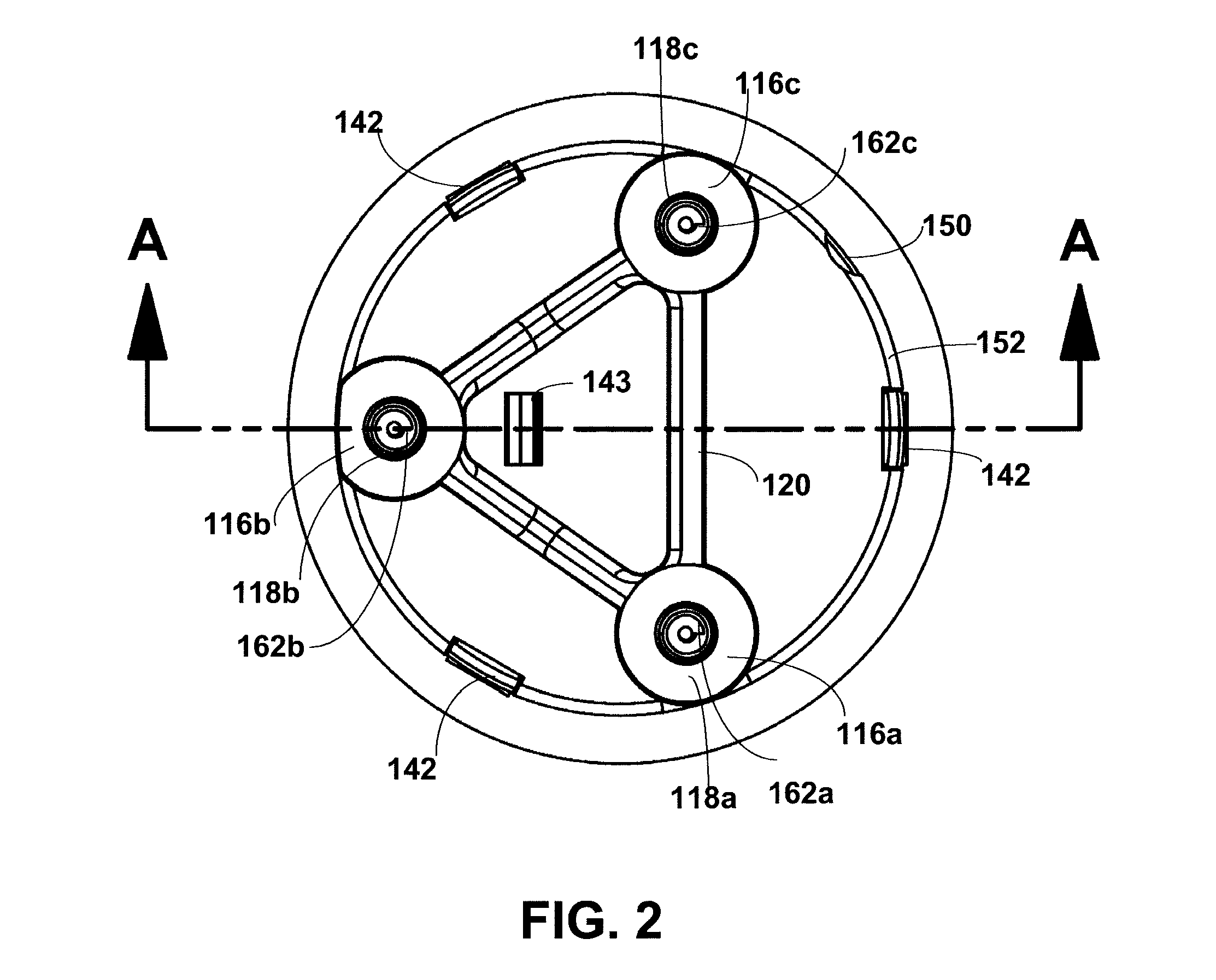

ActiveUS8129624B2Conducive to environmental protectionLess expensiveSludge treatmentVolume/mass flow measurementInterference fitElectronic board

A pressure sensor includes a sense element port, a support ring and a plurality of interference fit slits to provide a flexible interference fit between the sense element port and the support ring to form a substantially flush lap joint. The sensor also includes an electronics board inside the support ring and attached to planar mounting tabs which provide a stable mounting. Gel flow barriers protect electronics board features from unwanted non-conductive gel. Double-ended symmetrical, tapered contact springs provide manufacturing cost savings and contribute to improved alignment of an interface connector of the sensor.

Owner:SENSATA TECHNOLOGIES INC

Wireless Telemetry Electronic Circuit Board for High Temperature Environments

ActiveUS20100039779A1Semiconductor/solid-state device detailsSolid-state devicesActive componentCentrifugal force

A circuit assembly (34) resistant to high-temperature and high g centrifugal force is disclosed. A printed circuit board (42) is first fabricated from alumina and has conductive traces of said circuit formed thereon by the use of a thick film gold paste. Active and passive components of the circuit assembly are attached to the printed circuit board by means of gold powder diffused under high temperature. Gold wire is used for bonding between the circuit traces and the active components in order to complete the circuit assembly (34). Also, a method for manufacturing a circuit assembly resistant to elevated temperature is disclosed.

Owner:CREE FAYETTEVILLE +1

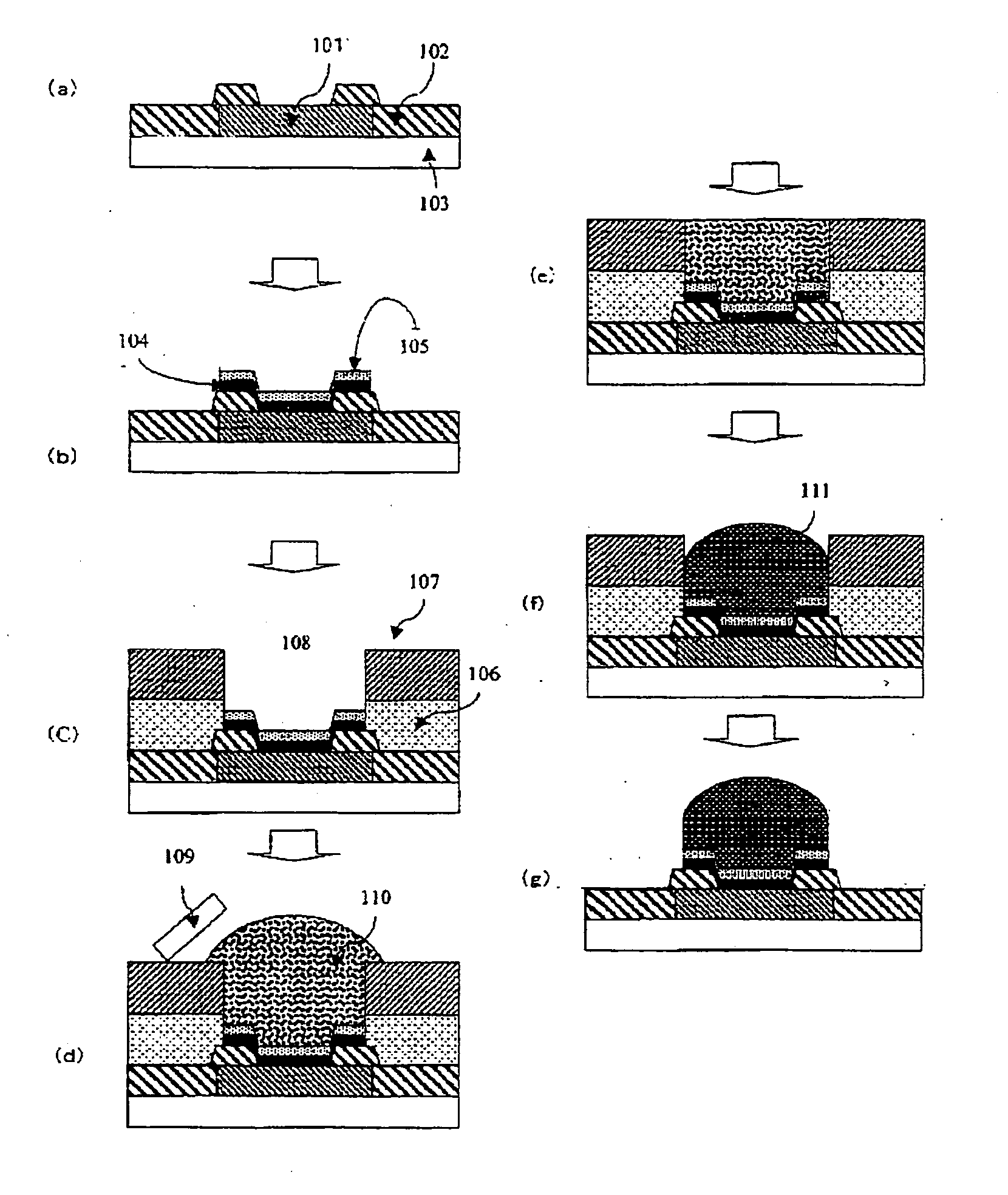

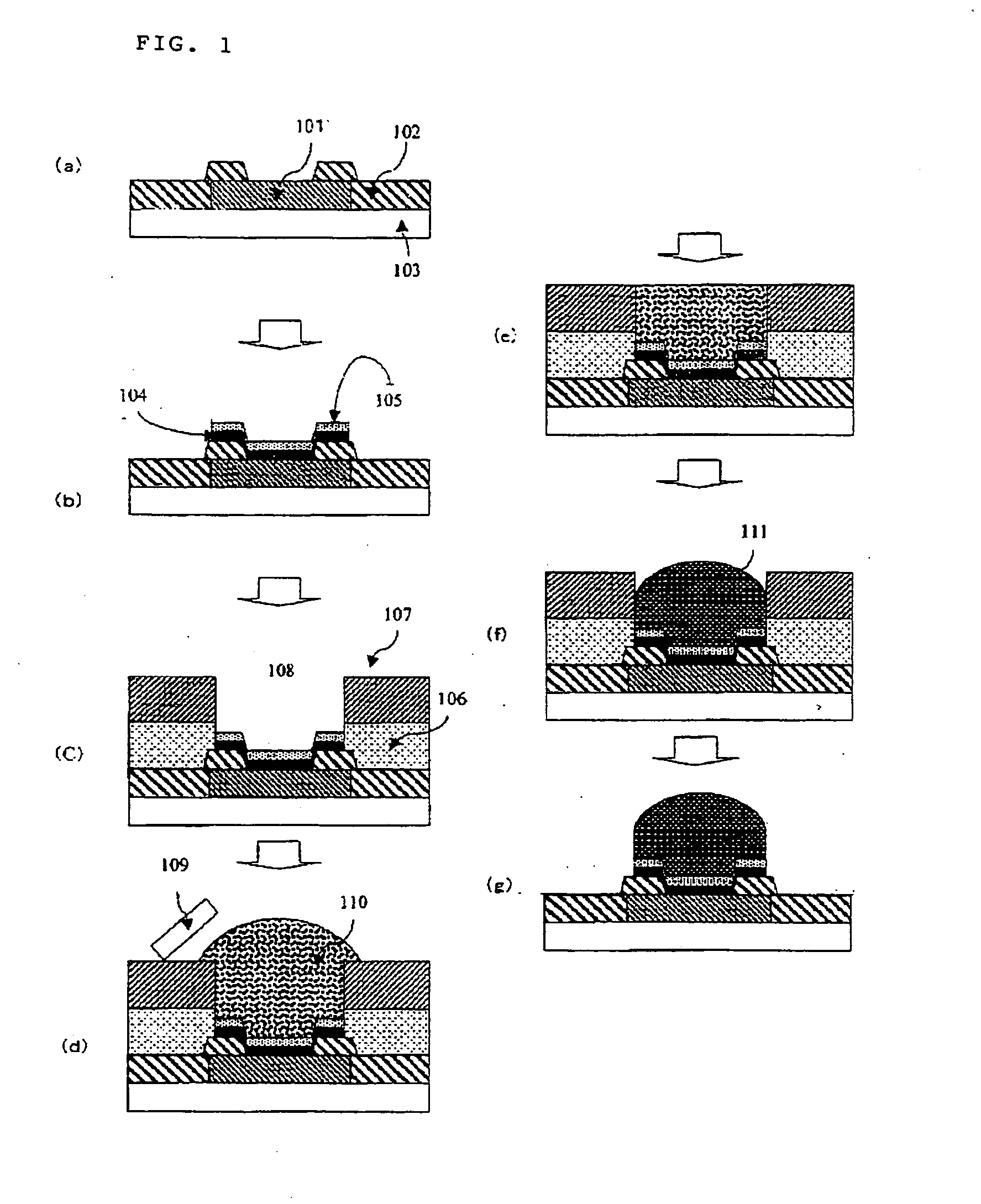

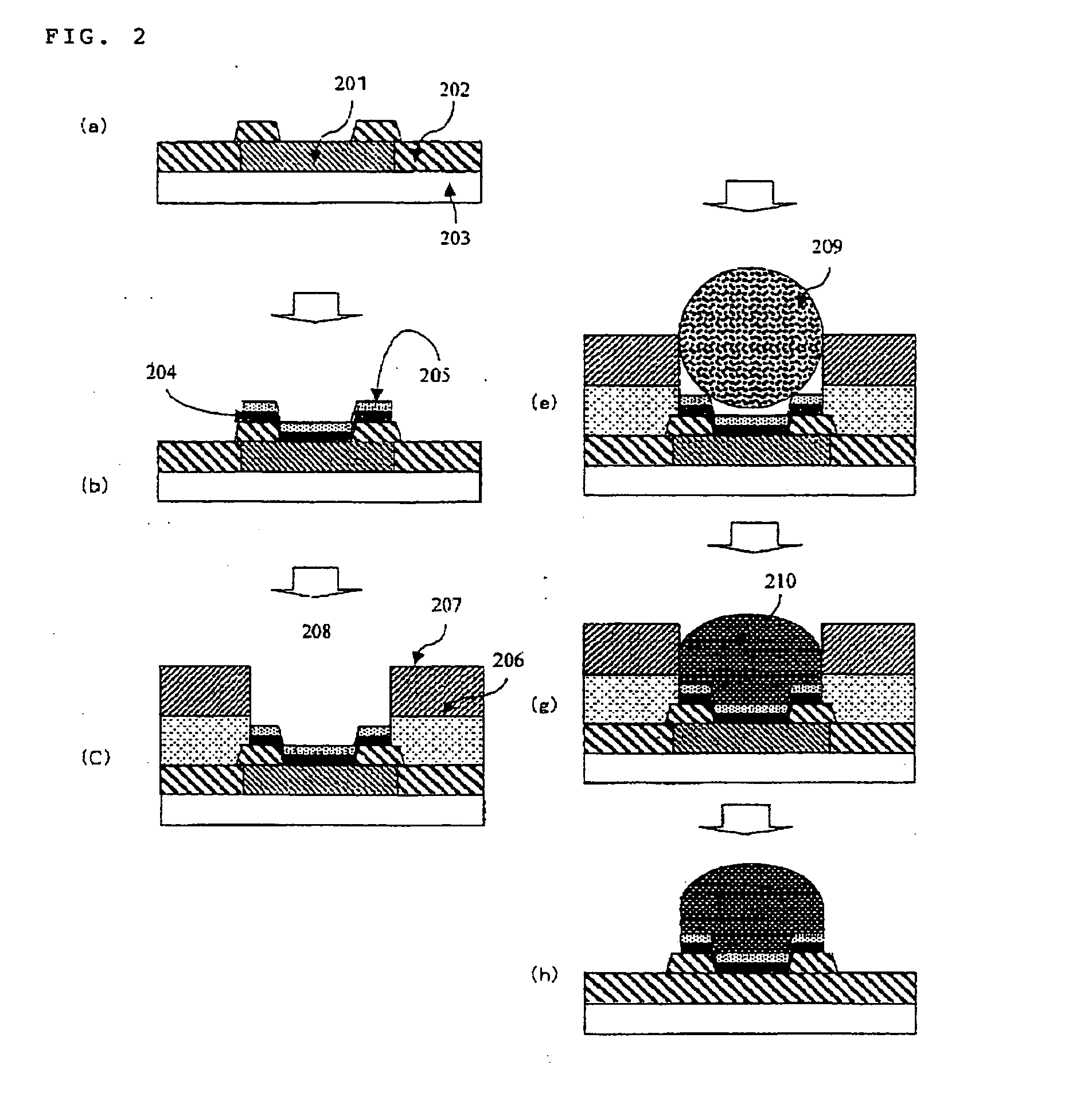

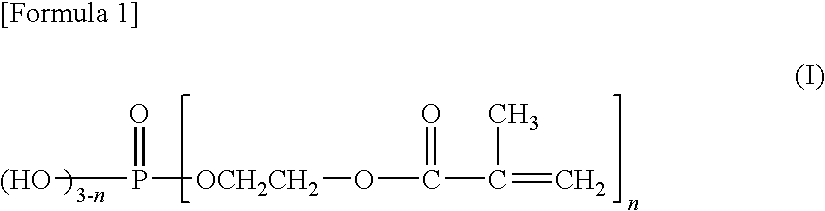

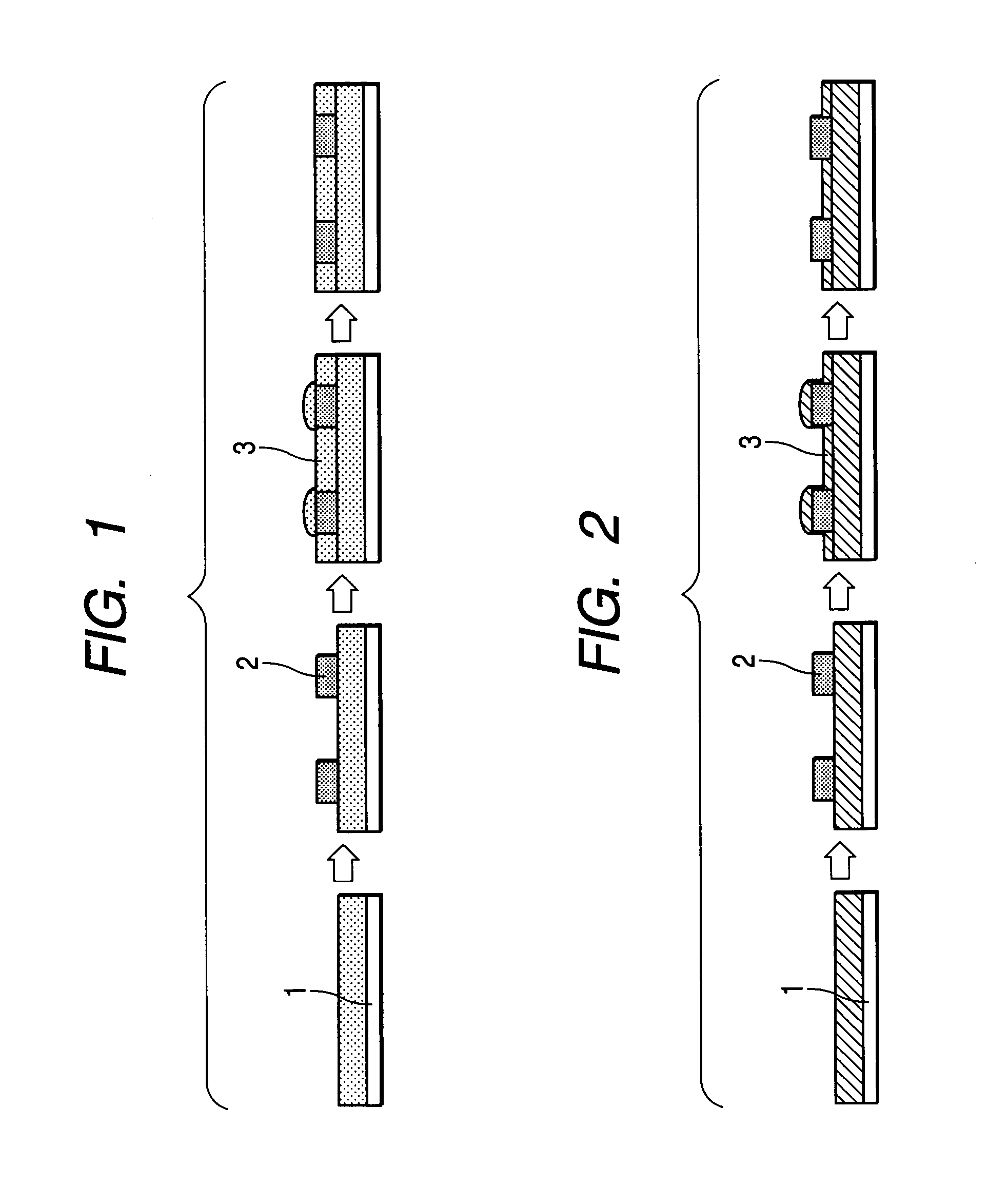

Bilayer Laminated Film for Bump Formation and Method of Bump Formation

InactiveUS20070237890A1Easy to peelEasy to removeImpression capsSolid-state devicesOrganic solventEngineering

A negative radiation-sensitive two-layer laminated film for forming bumps includes a lower layer that includes a composition including a polymer (A) with a specific structural unit and an organic solvent (B). A process for forming bumps uses the laminated film. The negative radiation-sensitive two-layer laminated film for forming bumps permits excellent printing of a solder paste, is patternable with good configuration, and is easily peeled from a substrate. The bump-forming process using the laminated film provides the same effects.

Owner:JSR CORPORATIOON

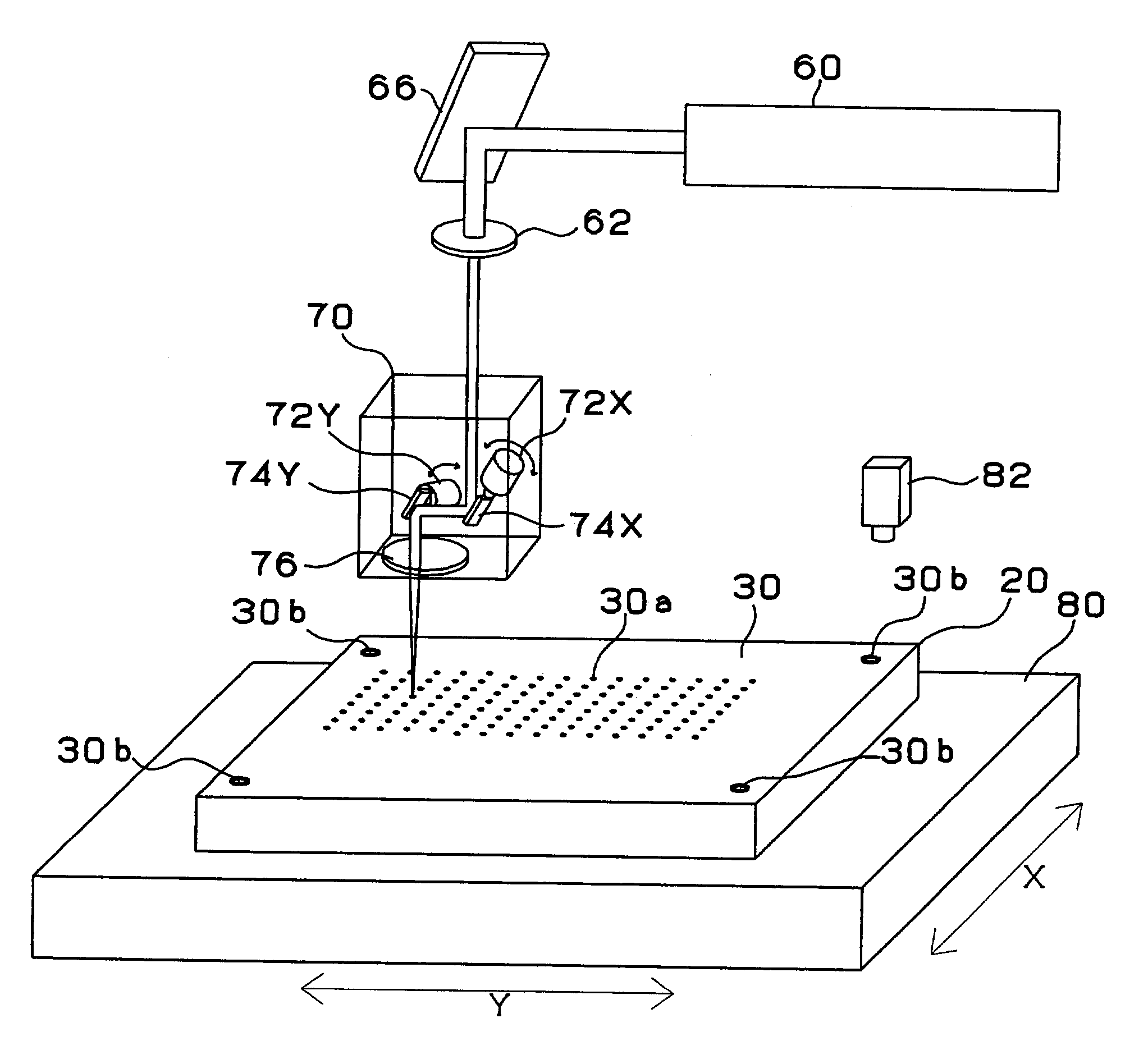

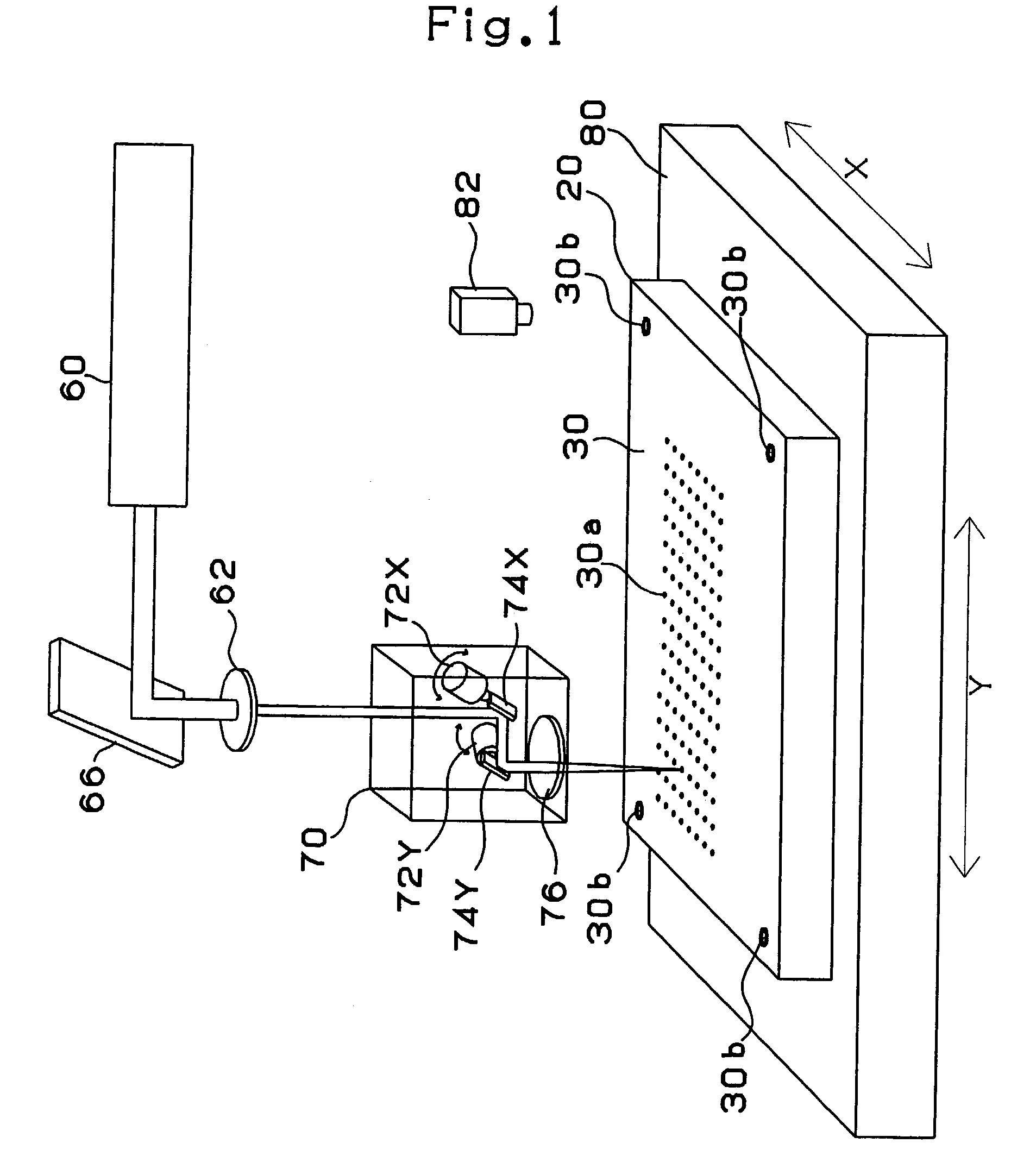

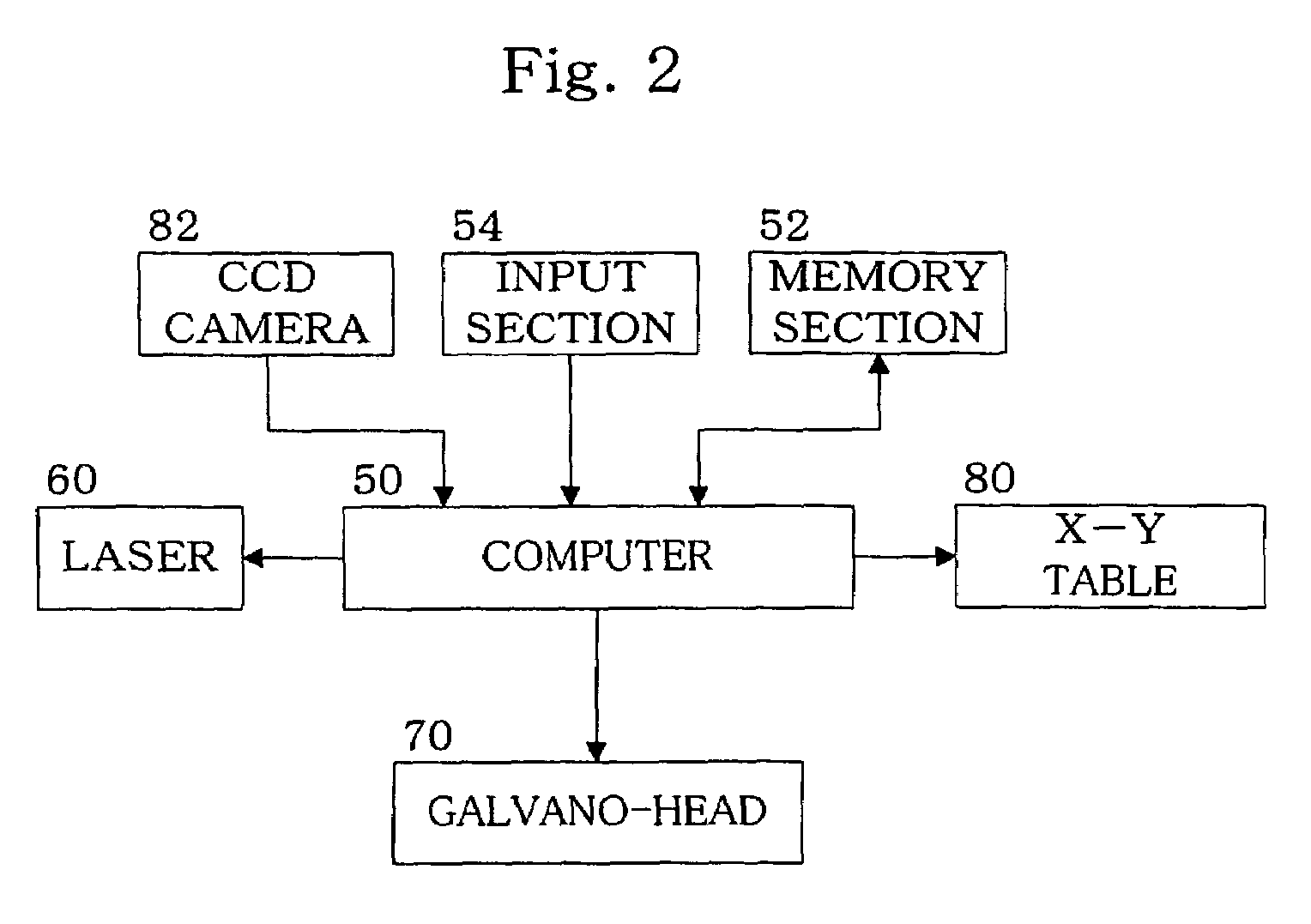

Process for producing a multi-layer printed wiring board

InactiveUS7127812B2Easy to disassembleNot to damageElectrical testingCircuit board tools positioningLaser beamsElectrical and Electronics engineering

A board 20 is provided with a Cu film 30 as a conformal mask, in which are formed a register mark 30b and an opening 3a through which a via hole is formed. A camera senses this register mark 30b so that the position of the board 30 is determined. A laser beam is directed to the approximate position of the opening 30a, so that the opening 26a through which the via hole is drilled is formed. The accuracy of the position of the opening of the via hole depends on the accuracy of the position of the opening 30a in the Cu film 30 as the conformal mask. Therefore, the via hole can be formed at an adequate position despite the low accuracy of the position for laser irradiation.

Owner:IBIDEN CO LTD

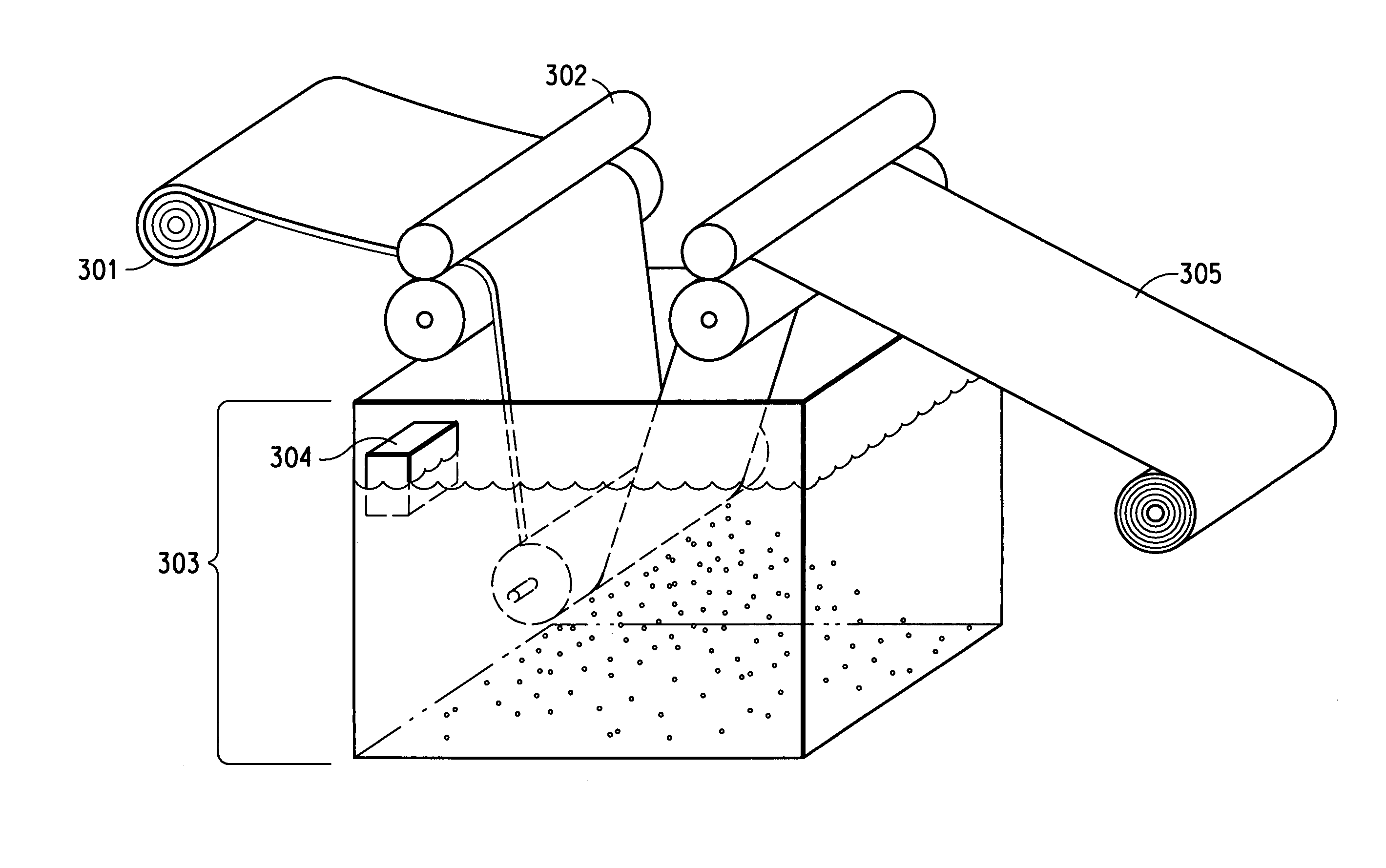

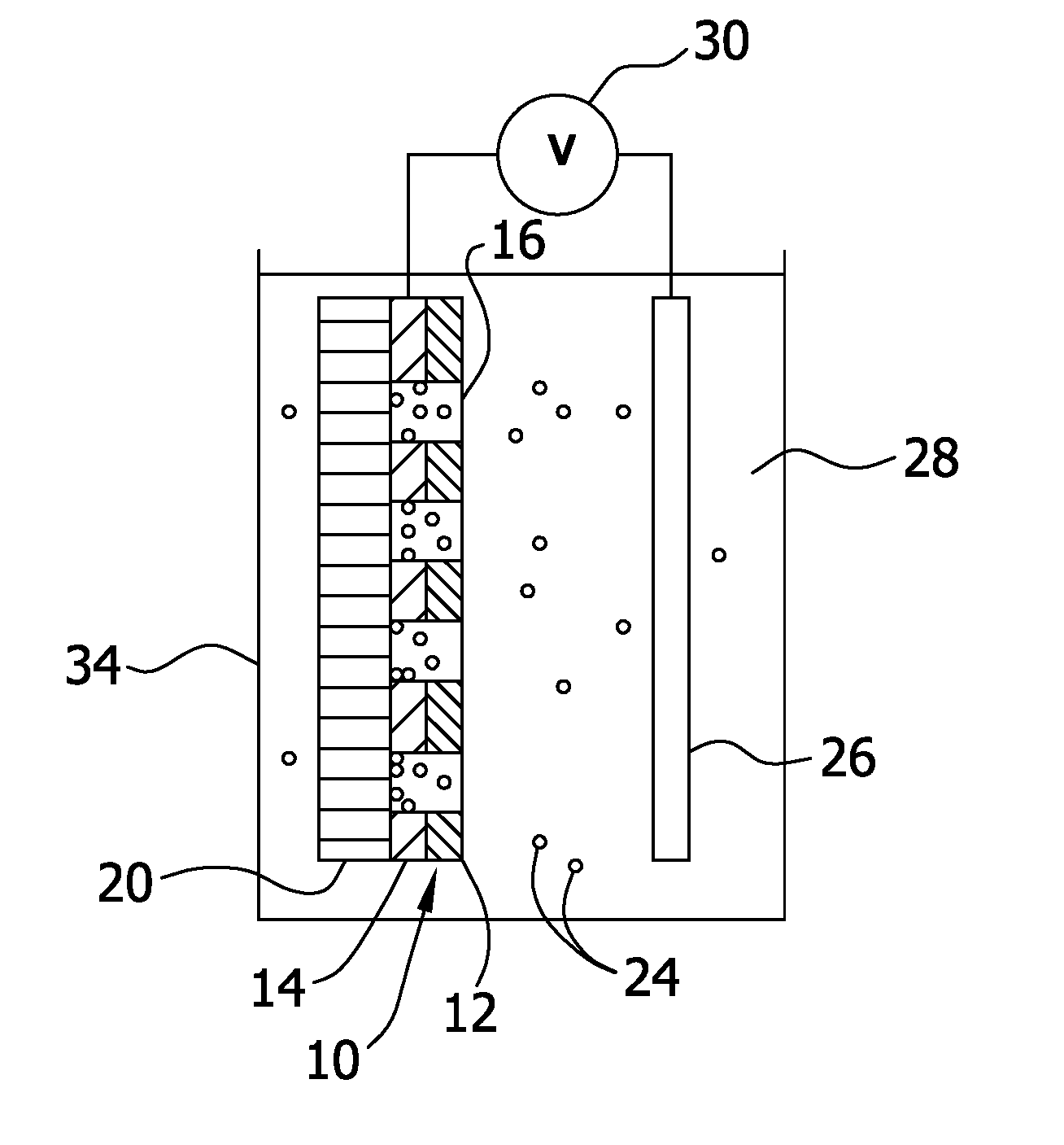

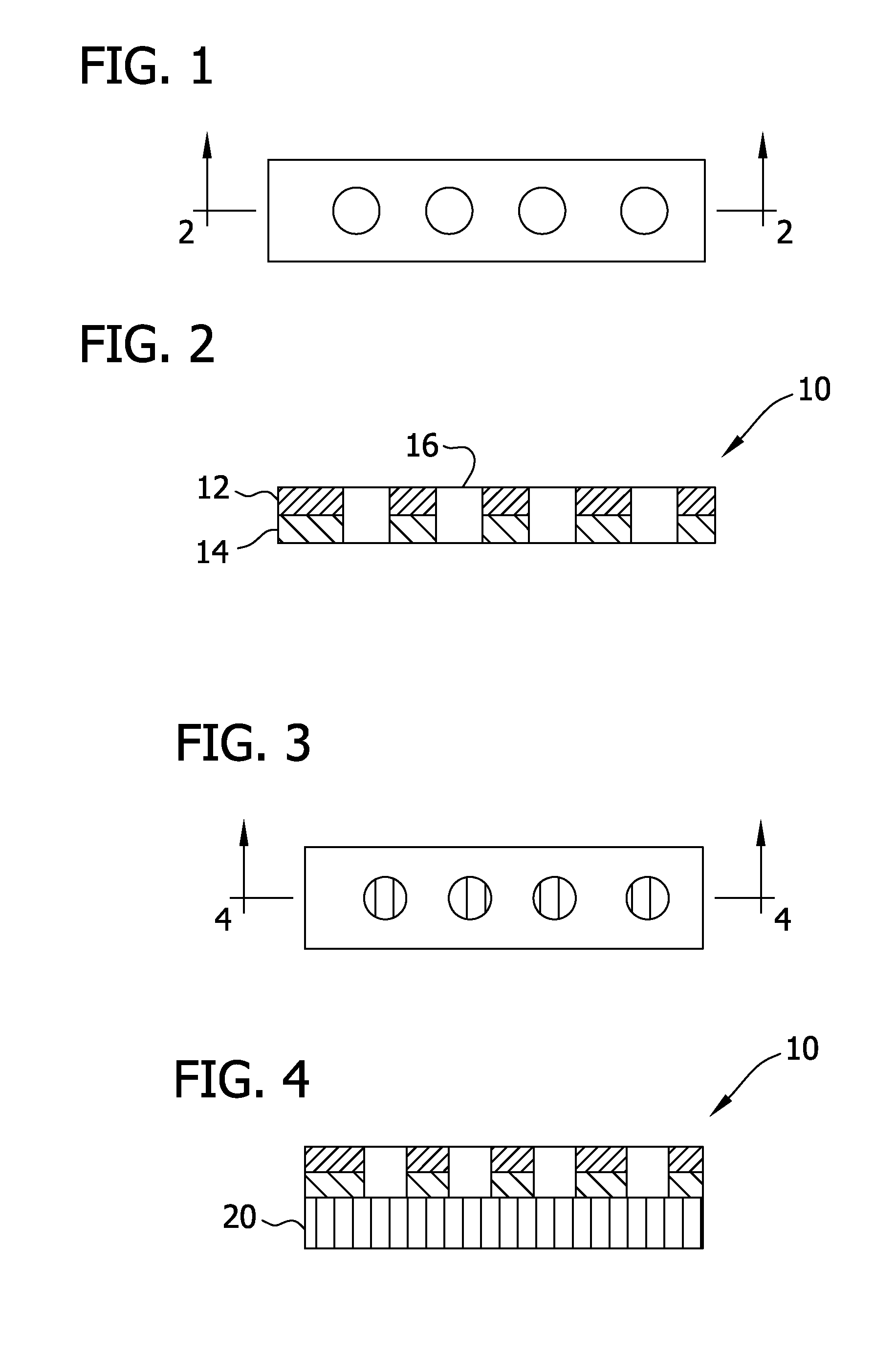

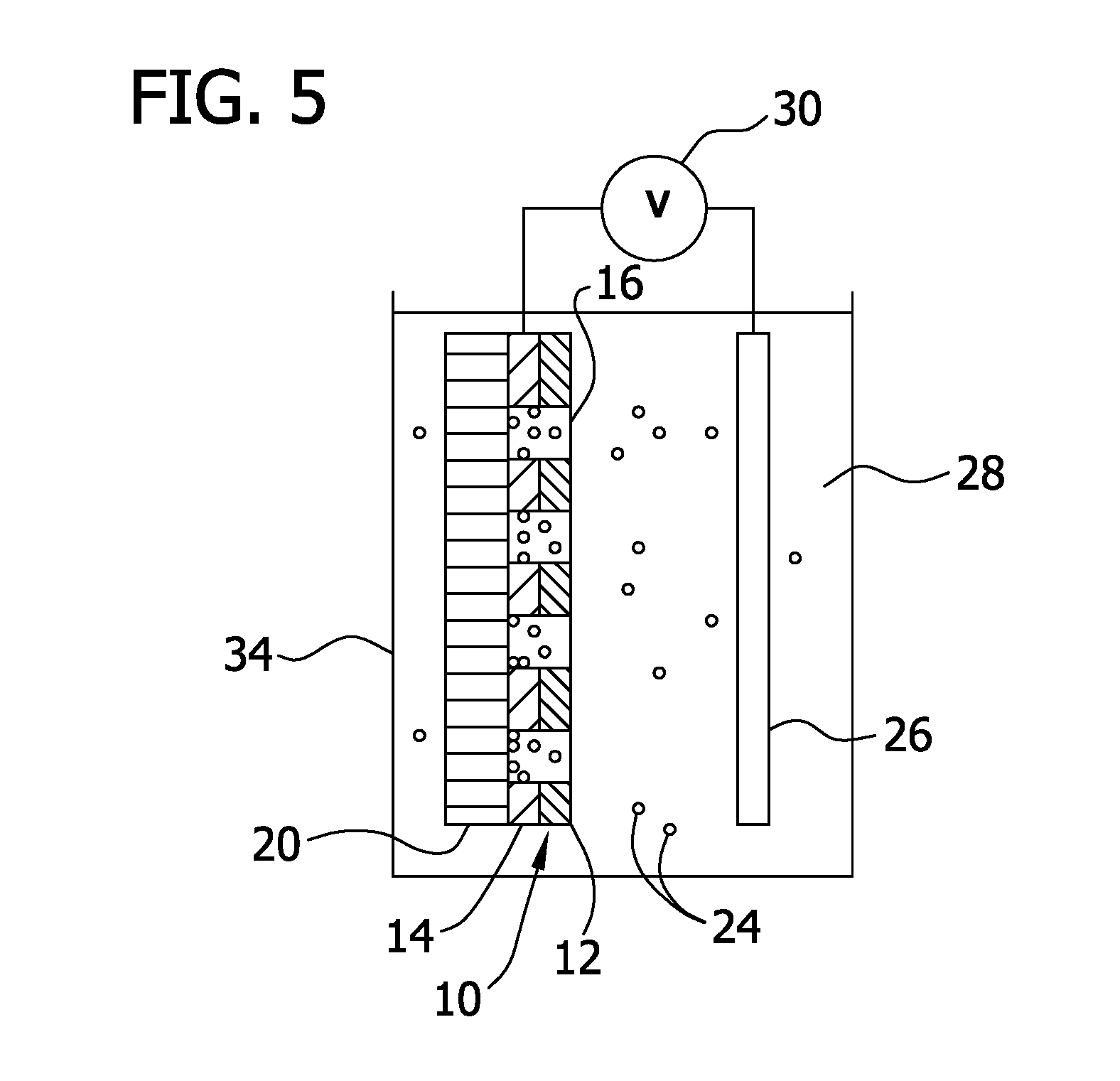

Mask and method for electrokinetic deposition and patterning process on substrates

ActiveUS20060260943A1Facilitate electrokinetic depositionVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsDielectric layerElectric potential

A mask for application to a substrate to facilitate electrokinetic deposition of charged particles onto the substrate, the mask comprising a conducting layer, a dielectric layer, and mask openings. A method for applying a pattern of charged particles to a substrate comprising applying the foregoing the substrate to yield a masked substrate; immersing the masked substrate in a bath containing the charged particles; and establishing an electrical potential between the conducting layer of the mask and a counter-electrode thereby electrokinetically depositing the particles through the mask openings onto areas of the substrate exposed in the mask openings. Products made by this method.

Owner:FRY S METALS INC

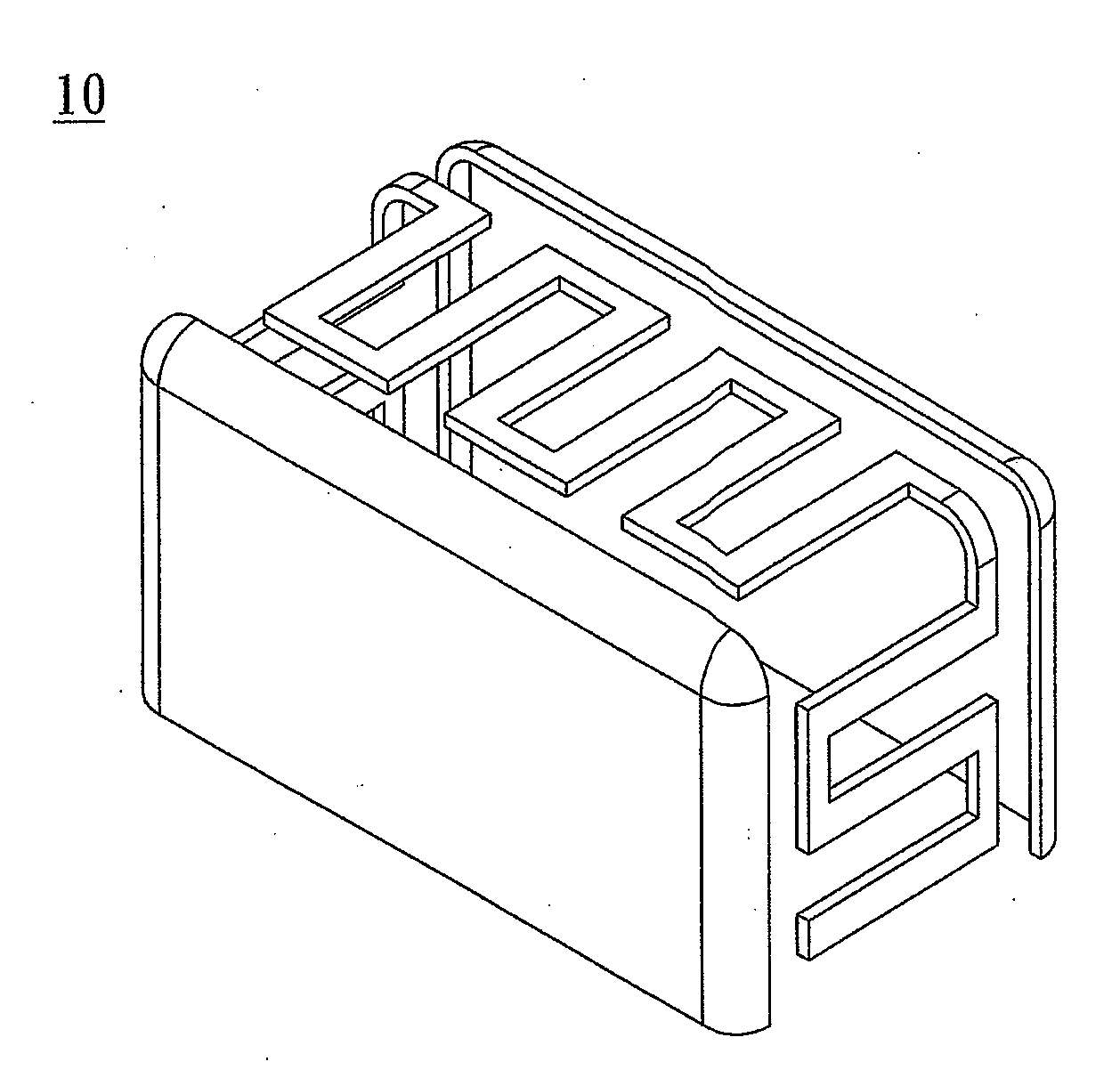

Multilayer ceramic electronic part, circuit board and method for producing ceramic green sheet used for manufacturing those part and circuit board

InactiveUS20050194084A1Dimensional precision can be increasedReduce layer thicknessSemiconductor/solid-state device manufacturingPhotomechanical treatmentMiniaturizationCase hardening

The present invention provides a method for manufacturing an electronic part that can cope with downsizing, improvement in performance and quality of a multilayer electronic part. A ceramic green sheet is produced by forming on a substrate or on a layer formed on a substrate an internal electrode having a predetermined thickness by a discretional process, forming a photosensitive ceramic slurry on a surface of the substrate or the layer and the internal electrode in such a way that its thickness just before exposure will be substantially equal to or smaller than the thickness of the internal electrode from the surface of the substrate or the layer, irradiating the photosensitive ceramic slurry with light from the upper side of the substrate to perform exposure while masking the internal electrode pattern, to selectively harden the surface of the photosensitive ceramic slurry, the exposure amount being controlled in such a way that the surface of the photosensitive ceramic slurry is hardened, and removing the portion of the photosensitive ceramic slurry that has not been exposed by a development process to expose a surface of the internal electrode pattern.

Owner:TDK CORPARATION

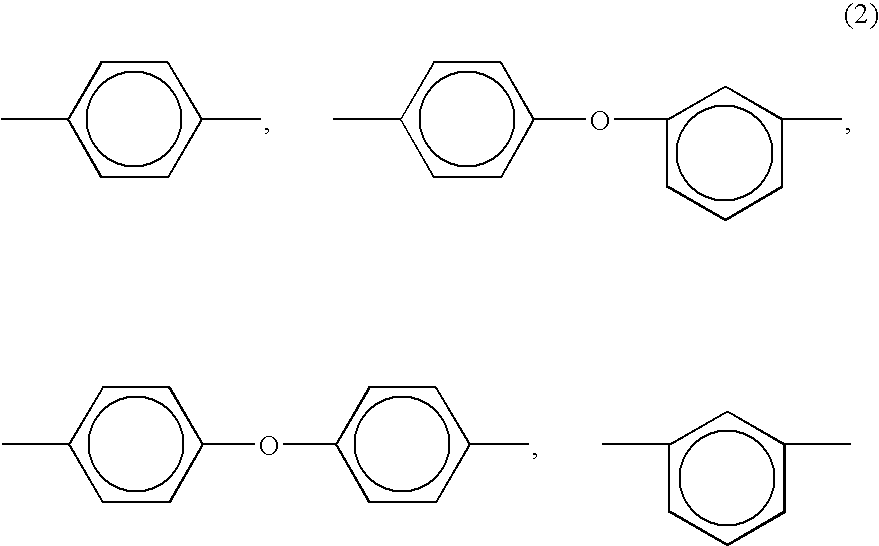

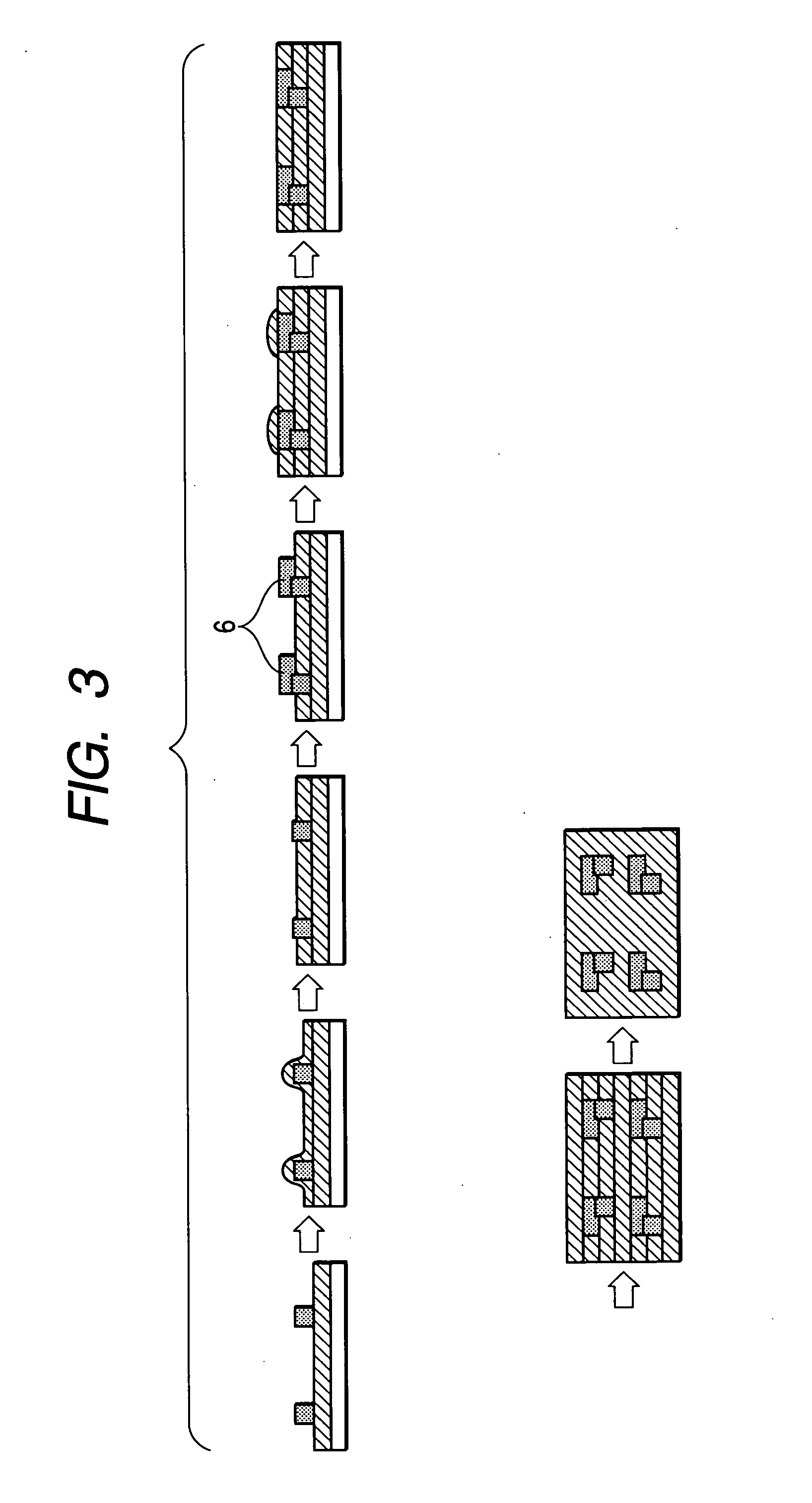

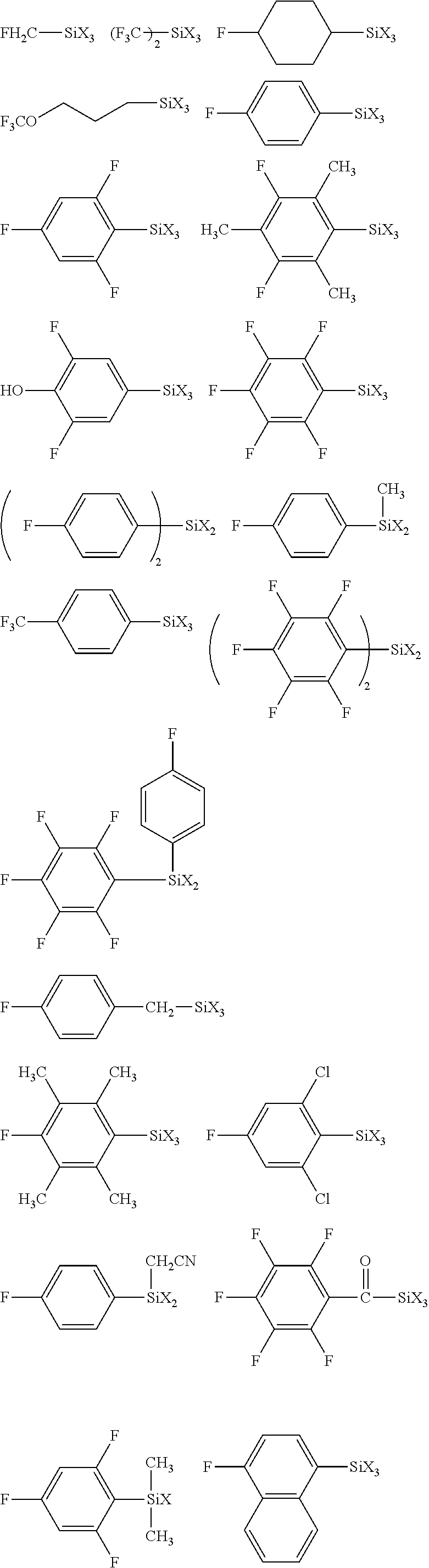

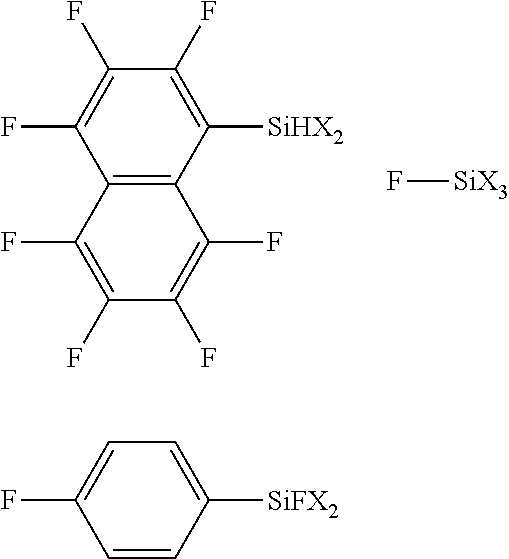

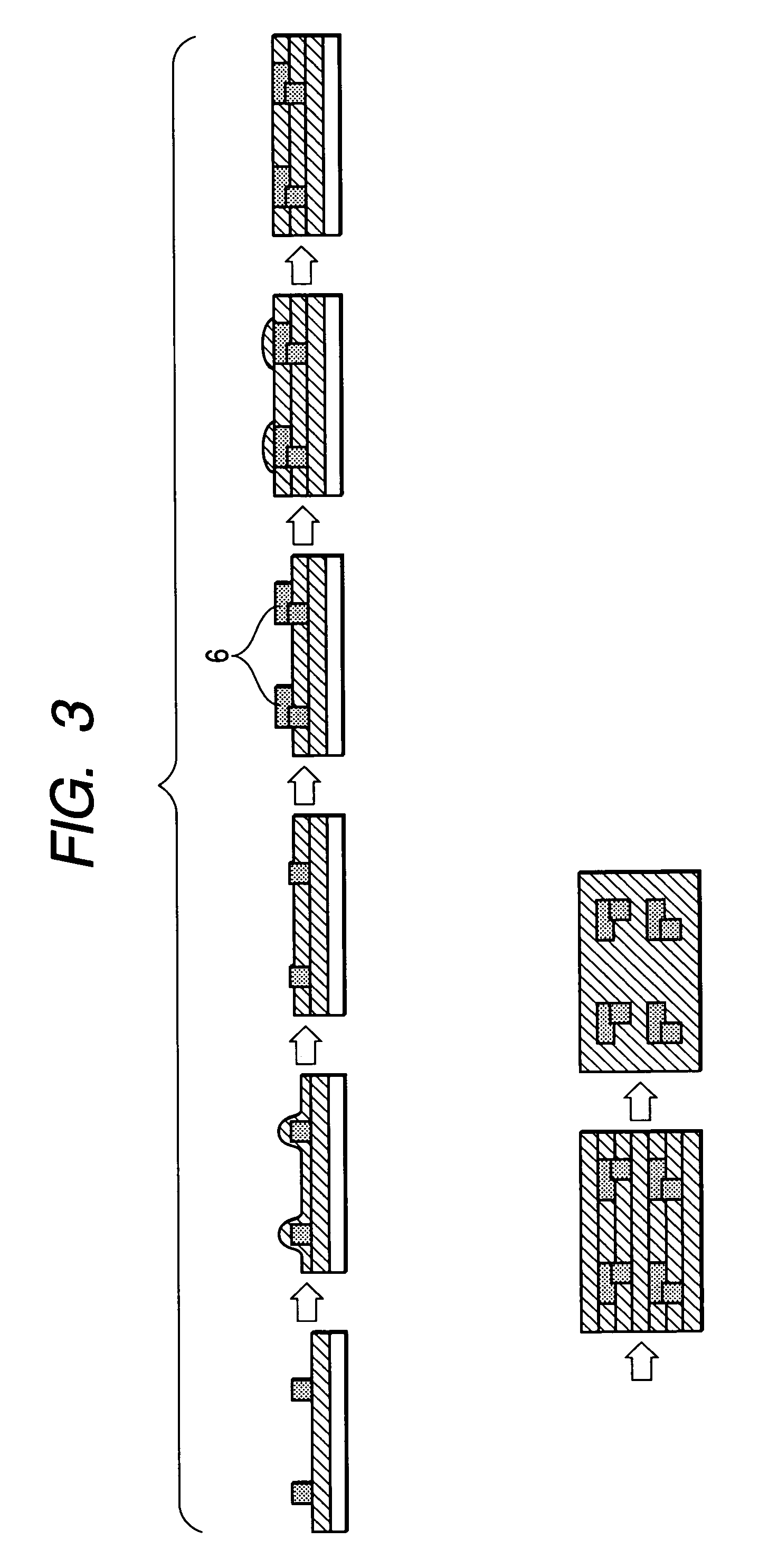

Method for forming pattern, and polysiloxane composition

ActiveUS20150048046A1Conveniently synthesizedGood effectDecorative surface effectsSemiconductor/solid-state device manufacturingResistSilicon membrane

A pattern-forming method in which processibility of a silicon-containing film in etching with a fluorine gas and resistance against etching with an oxygen gas can be together improved in a multilayer resist process to form a finer pattern. Provided is a pattern-forming method that includes the steps of (1) providing a silicon-containing film on the upper face side of a substrate to be processed using a polysiloxane composition; (2) forming a resist pattern on the silicon-containing film; (3) dry-etching the silicon-containing film using the resist pattern as a mask to form a silicon-containing pattern; and (4) dry-etching the substrate to be processed using the silicon-containing pattern as a mask to form a pattern, in which the polysiloxane composition includes (A) a polysiloxane containing a fluorine atom, and (B) a crosslinking accelerator.

Owner:JSR CORPORATIOON

Pressure sensor

ActiveUS20110290539A1Facilitate wire bondingImprove visibilitySludge treatmentVolume/mass flow measurementInterference fitEngineering

A pressure sensor includes a sense element port, a support ring and a plurality of interference fit slits to provide a flexible interference fit between the sense element port and the support ring to form a substantially flush lap joint. The sensor also includes an electronics board inside the support ring and attached to planar mounting tabs which provide a stable mounting. Gel flow barriers protect electronics board features from unwanted non-conductive gel. Double-ended symmetrical, tapered contact springs provide manufacturing cost savings and contribute to improved alignment of an interface connector of the sensor.

Owner:SENSATA TECHNOLOGIES INC

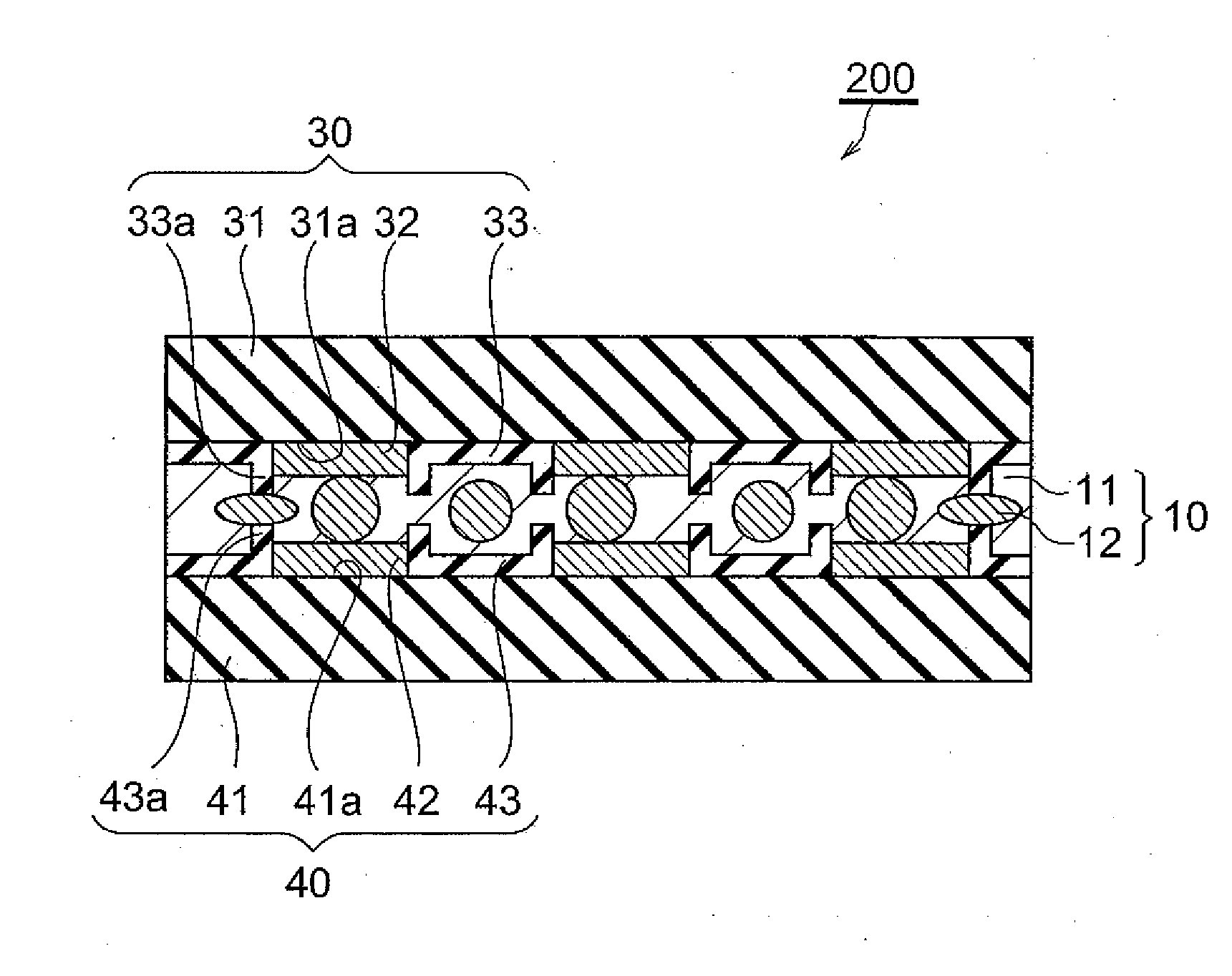

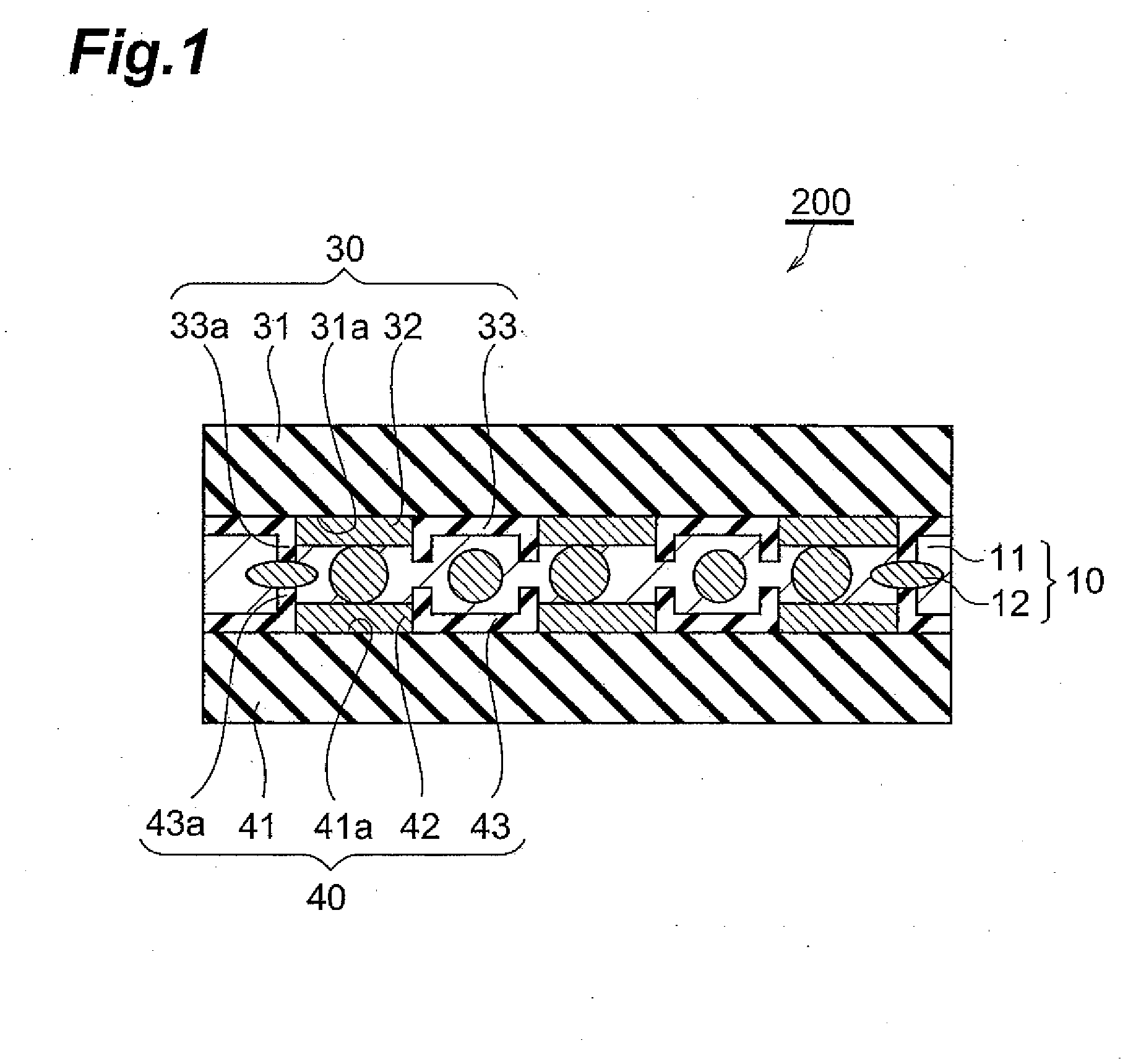

Circuit connecting material, film-form circuit connecting material using the same, circuit member connecting structure and method of manufacturing the same

InactiveUS20090321116A1Reduce connection resistanceLong-term reliabilitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionHardness

The present invention is a circuit connecting material used for the mutual connection of a circuit member in which electrodes and insulating layers are formed adjacent to each other on the surface of a board, and a circuit member in which electrodes and insulating layers are formed adjacent to each other on the surface of a board, with the edge parts and of the insulating layers being formed with a greater thickness than the electrodes on the basis of the main surfaces, wherein this circuit connecting material contains a bonding agent composition and conductive particles that have a mean particle size of 1 μm or greater but less than 10 μm and a hardness of 1.961 to 6.865 GPa, and this circuit connecting material exhibits a storage elastic modulus of 0.5 to 3 GPa at 40° C. and a mean coefficient of thermal expansion of 30 to 200 ppm / ° C. at from 25° C. to 100° C. when subjected to the curing treatment.

Owner:RESONAC CORPORATION

Printed circuit board processing method adopting etching process for forming backdrilled holes

InactiveCN106358385AEtched clean and thoroughMedia thickness is not requiredPrinted circuit aspectsPatterning and lithographyTinningRejection rate

The invention discloses a printed circuit board processing method adopting an etching process for forming backdrilled holes. The method comprises the following steps: 1) completing normal drilling and electroplating on the surface of a printed circuit board; 2) pasting a layer of dry film on the surface of the printed circuit board; 3) removing the dry film in positions other than to-be-backdrilled positions with a chemical, only reserving the dry film in positions to be backdrilled, and reserving chemical via holes in the dry film at the holes; 4) performing tinning in the holes and in positions without the dry film on the printed circuit board; 5) removing the dry film with the chemical and exposing the to-be-backdrilled positions; 6) etching the holes to the required depth; 7) removing the tin layer on the printed circuit board and the hole walls. The etching process replaces backdrilling, etching is more clean and thorough and has no requirements for the medium thickness, Stub is more uniform, and accordingly, signals of the printed circuit board cannot be influenced, the product quality is good, and the rejection rate is low.

Owner:开平依利安达电子第三有限公司

Method for manufacturing ceramic green sheet and method for manufacturing electronic part using that ceramic green sheet

InactiveUS20050079450A1Quality improvementReduce variationConductive/insulating/magnetic material on magnetic film applicationFixed inductancesUltraviolet lightsTransmittance

There is provided a sheet used for manufacturing multilayer electronic parts in which accuracy in shape and formation position and uniformity in thickness of a complex configuration with recesses and projections of an insulating layer or the like are assured. A layer made of a photosensitive material containing a powder having a specific electric characteristic is formed on a light transmissive base member. A mask having a plurality of patterns with different transmittances for ultraviolet light is disposed on the back side of the base member. The photosensitive material is subjected to an exposure process in which it is irradiated with ultraviolet light or the like through the mask. The photosensitive material is subjected to development process after the exposure process.

Owner:TDK CORPARATION

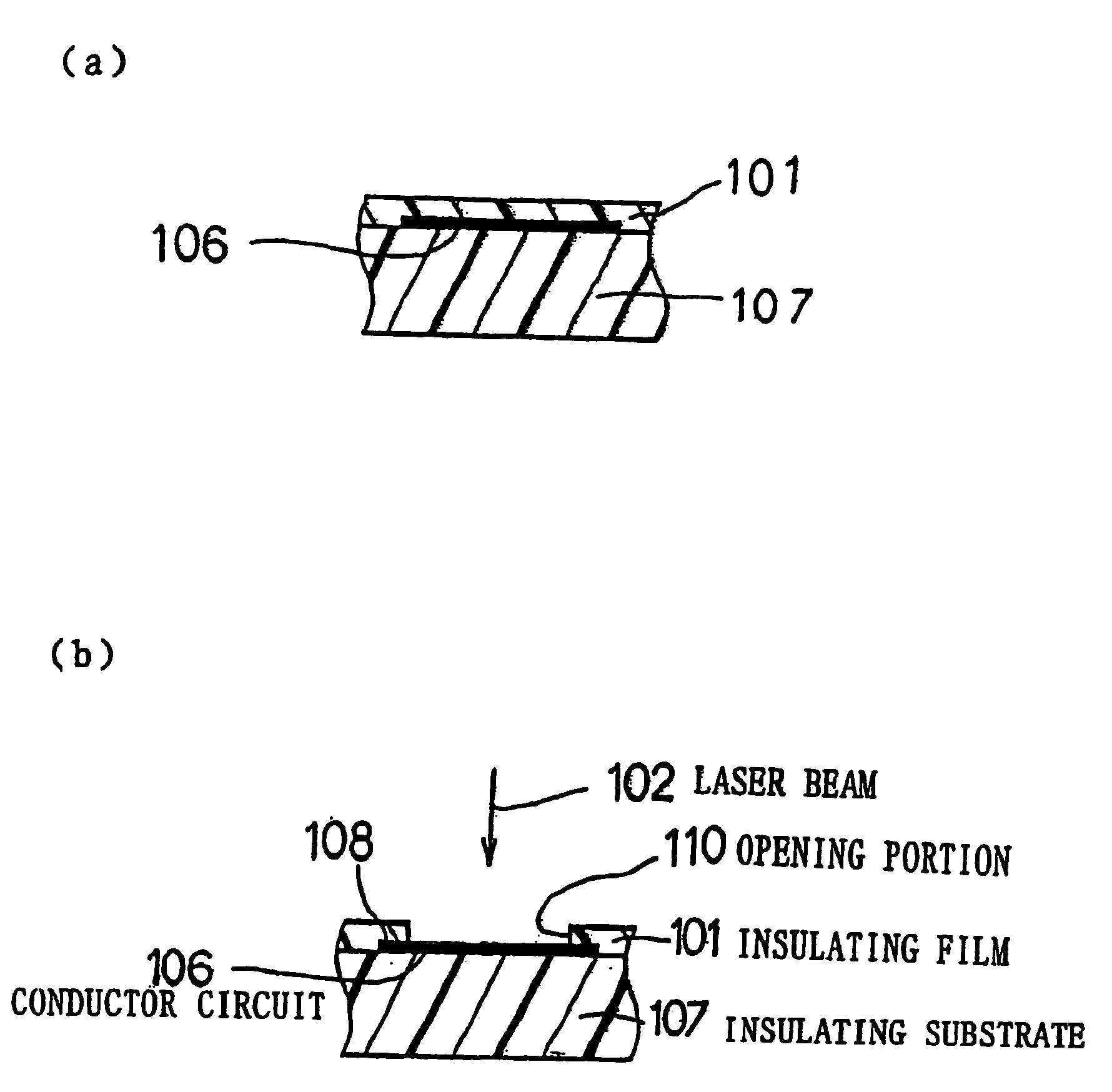

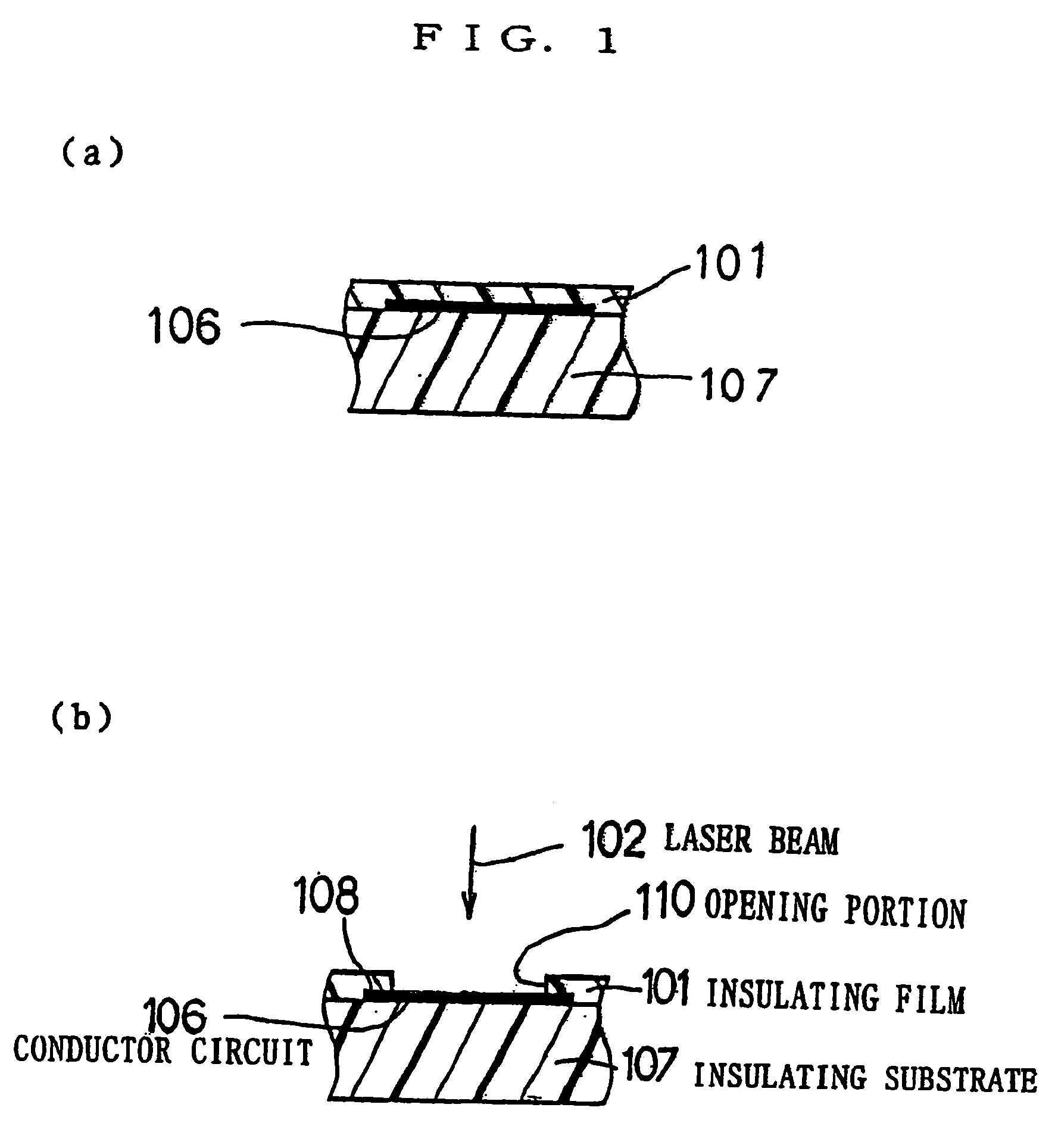

Printed wiring board and method of manufacturing the same

InactiveUS20060042824A1Generation of stress of the solder resist is reducedConductor circuit is improvedSemiconductor/solid-state device detailsSolid-state devicesResistElectrical conductor

A solder resist comprising a thermosetting resin is printed on a surface of an insulating board (7) having a conductor circuit (6). The solder resist is then heat-cured to form an insulating film (1) having a low thermal expansion coefficient. A laser beam (2) is then applied to the portion of the insulating film in which an opening is to be formed, to burn off the same portion for forming an opening (10), whereby the conductor circuit (6) is exposed. This opening may be formed as a hole for conduction by forming a metal plating film on an inner surface thereof. It is preferable that an external connecting pad be formed so as to cover the opening. The film of coating of a metal is formed by using an electric plating lead, which is preferably cut off by a laser beam after the electric plating has finished.

Owner:IBIDEN CO LTD

Multilayer ceramic electronic part, circuit board and method for producing ceramic green sheet used for manufacturing those part and circuit board

InactiveUS7232496B2Prevent stack misalignmentImprove accuracyPhotomechanical treatmentPatterning and lithographyMiniaturizationCase hardening

The present invention provides a method for manufacturing an electronic part that can cope with downsizing, improvement in performance and quality of a multilayer electronic part. A ceramic green sheet is produced by forming on a substrate or on a layer formed on a substrate an internal electrode having a predetermined thickness by a discretional process, forming a photosensitive ceramic slurry on a surface of the substrate or the layer and the internal electrode in such a way that its thickness just before exposure will be substantially equal to or smaller than the thickness of the internal electrode from the surface of the substrate or the layer, irradiating the photosensitive ceramic slurry with light from the upper side of the substrate to perform exposure while masking the internal electrode pattern, to selectively harden the surface of the photosensitive ceramic slurry, the exposure amount being controlled in such a way that the surface of the photosensitive ceramic slurry is hardened, and removing the portion of the photosensitive ceramic slurry that has not been exposed by a development process to expose a surface of the internal electrode pattern.

Owner:TDK CORPARATION

Solder joint for an electrical conductor and a window pane including same

ActiveUS9272371B2Printed circuit aspectsTransparent/reflecting heating arrangementsElectrical conductorReaction zone

A solder joint is disposed on an electrical conductor which comprises silver. The solder joint comprises bismuth and tin. The solder joint has a microstructure comprising a bismuth-rich solder bulk and a silver-solder reaction zone. The bismuth-rich solder bulk is disposed adjacent to the silver-solder reaction zone. The solder joint comprises a plurality of bismuth-rich grains formed from bismuth and substantially dispersed throughout at least the bismuth-rich solder bulk of the solder joint. A window pane comprising the solder joint is also disclosed.

Owner:AGC FLAT GLASS NORTH AMERICA INC +1

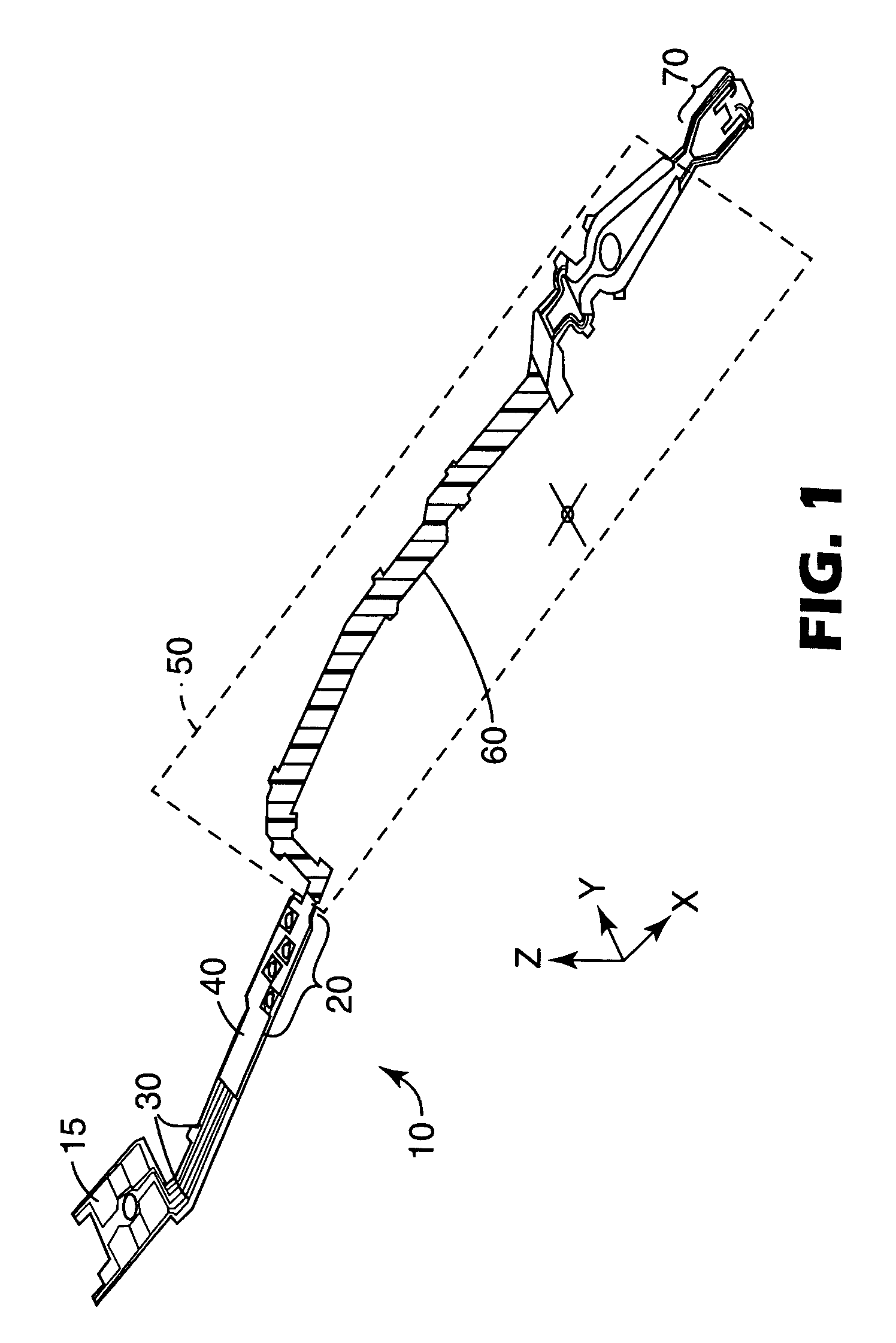

Flexible circuit with electrostatic damage limiting feature

InactiveUS7135203B2Easy dischargeReduce voltageElectrostatic discharge protectionRecord information storageFlexible circuitsConductive polymer

A flexible circuit incorporating an electrostatic discharge limiting feature, comprising a dielectric substrate selected from polyimide or liquid crystal polymer film having at least one conductive trace coated on at least one surface of the substrate wherein the discharge limiting feature includes a thin conductive polymer coating selectively applied over a at least a portion of the non-critical region of the circuit, said feature reducing the surface resistivity of the circuit to about 104 ohms to about 108 ohms and having tribocharging of less than about 50 V.

Owner:3M INNOVATIVE PROPERTIES CO

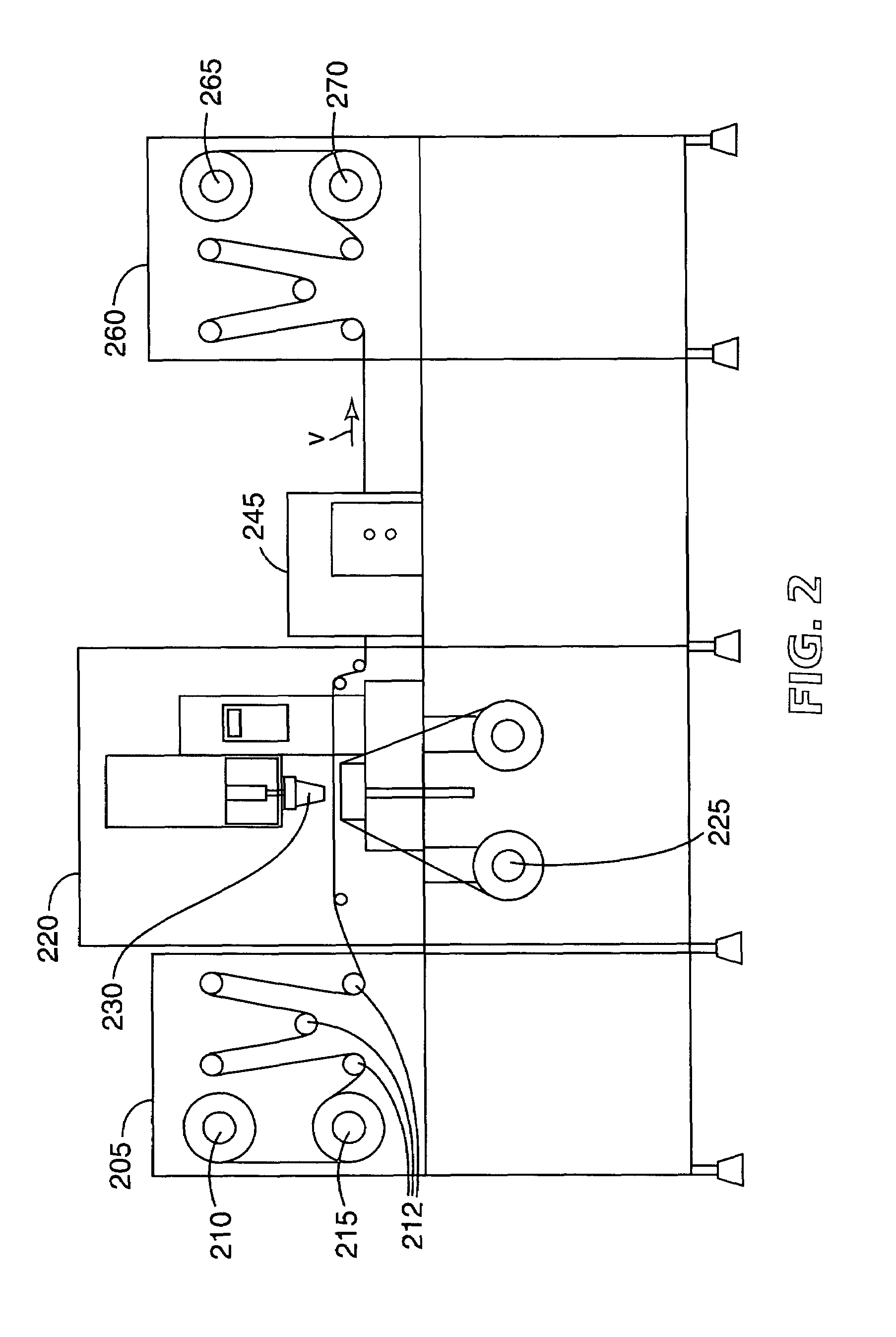

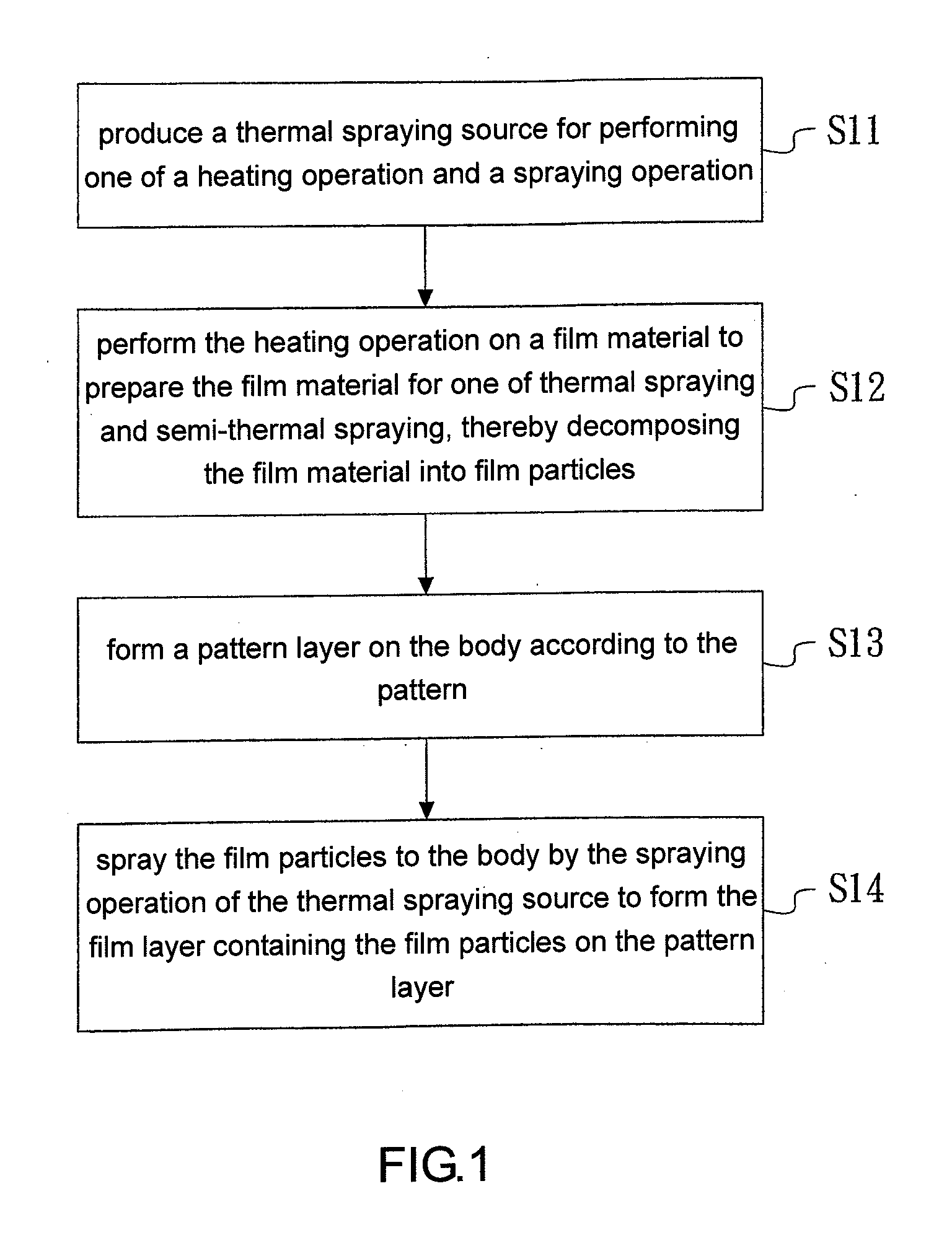

Conductive pattern film substrate and manufacturing method

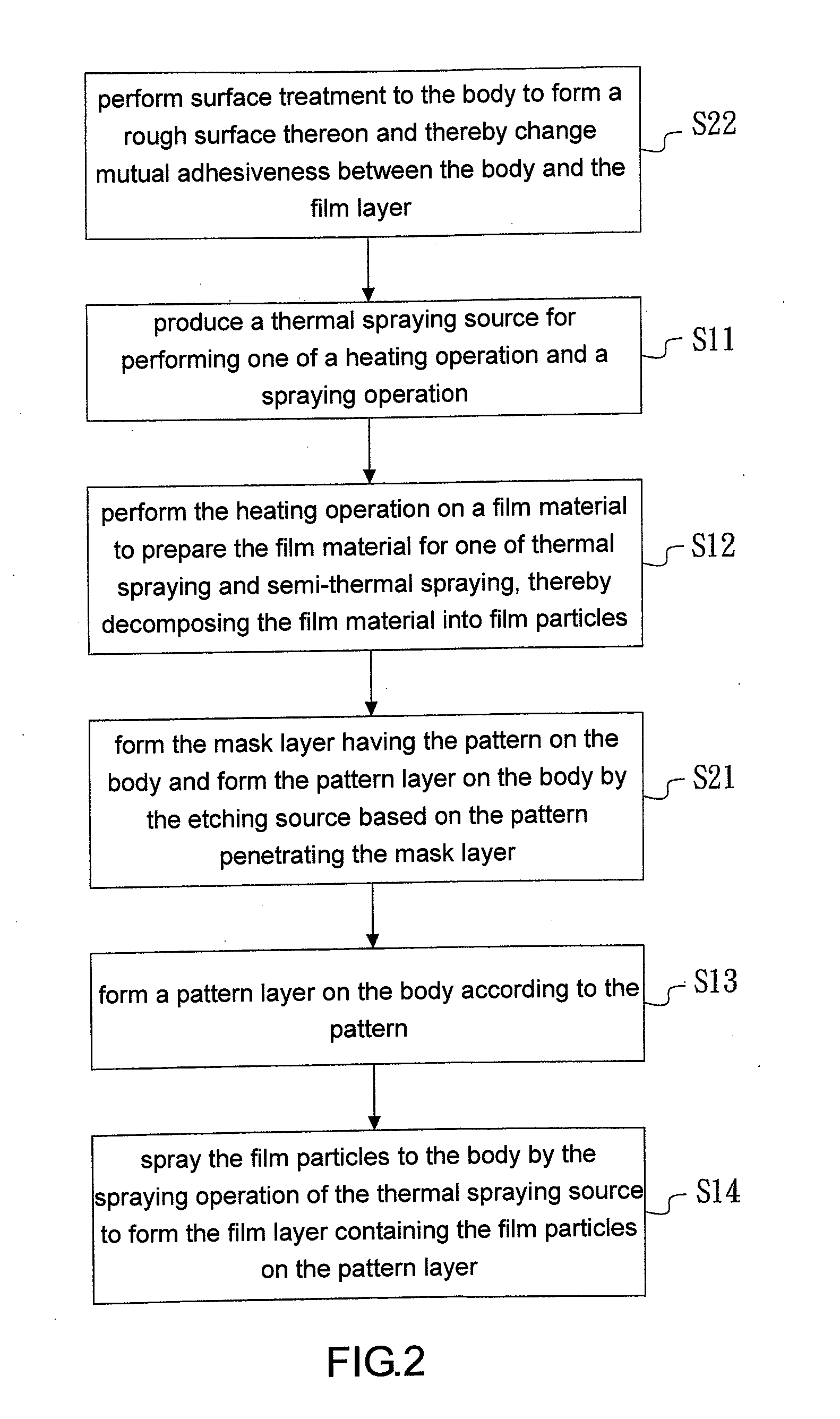

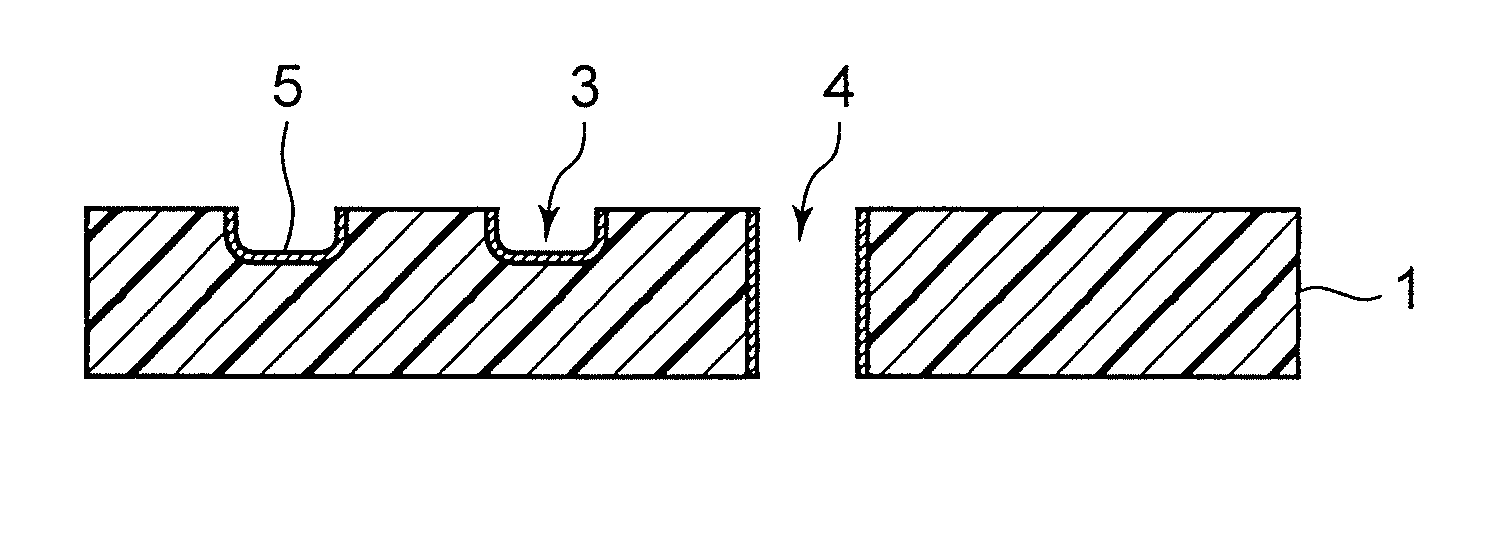

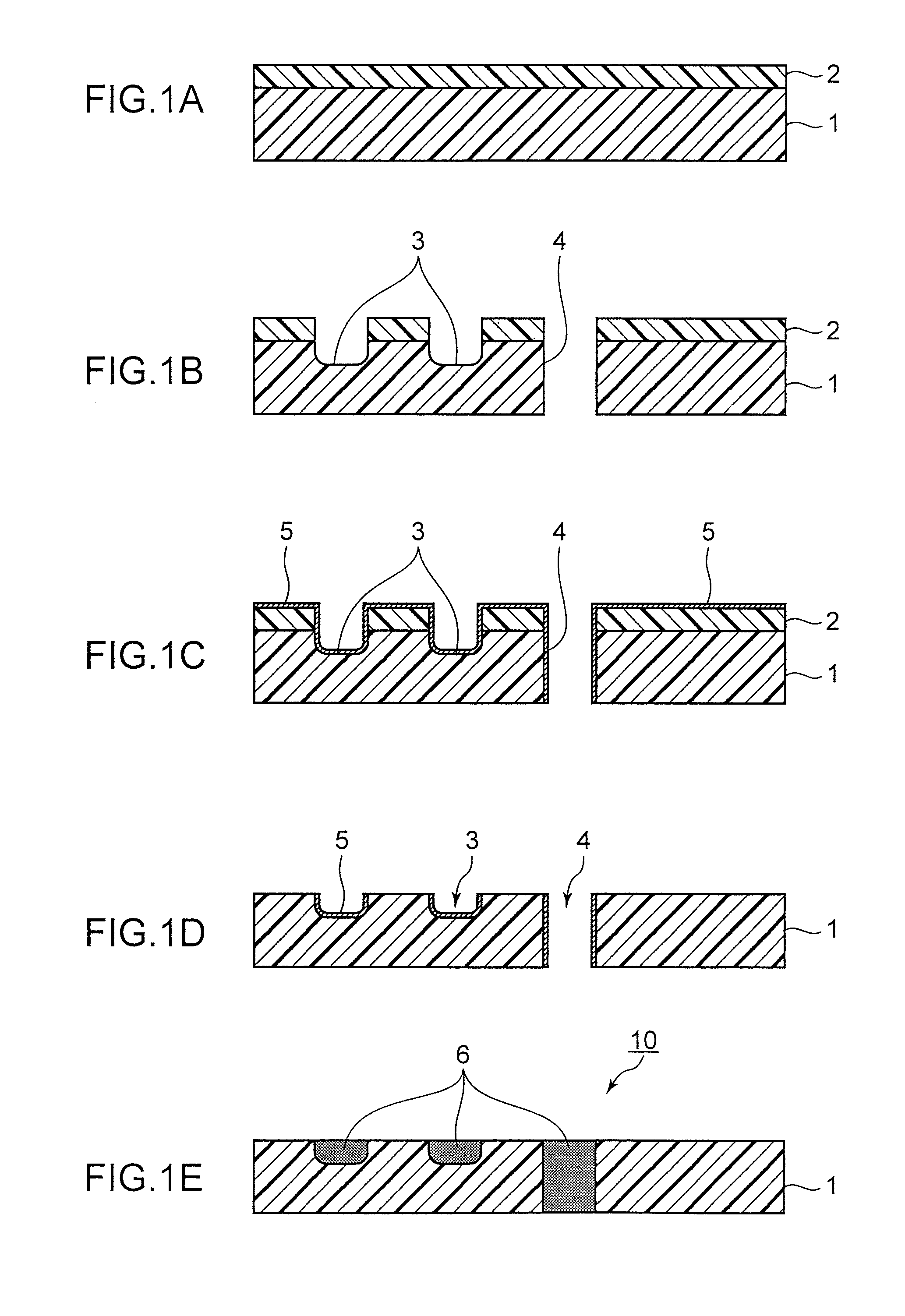

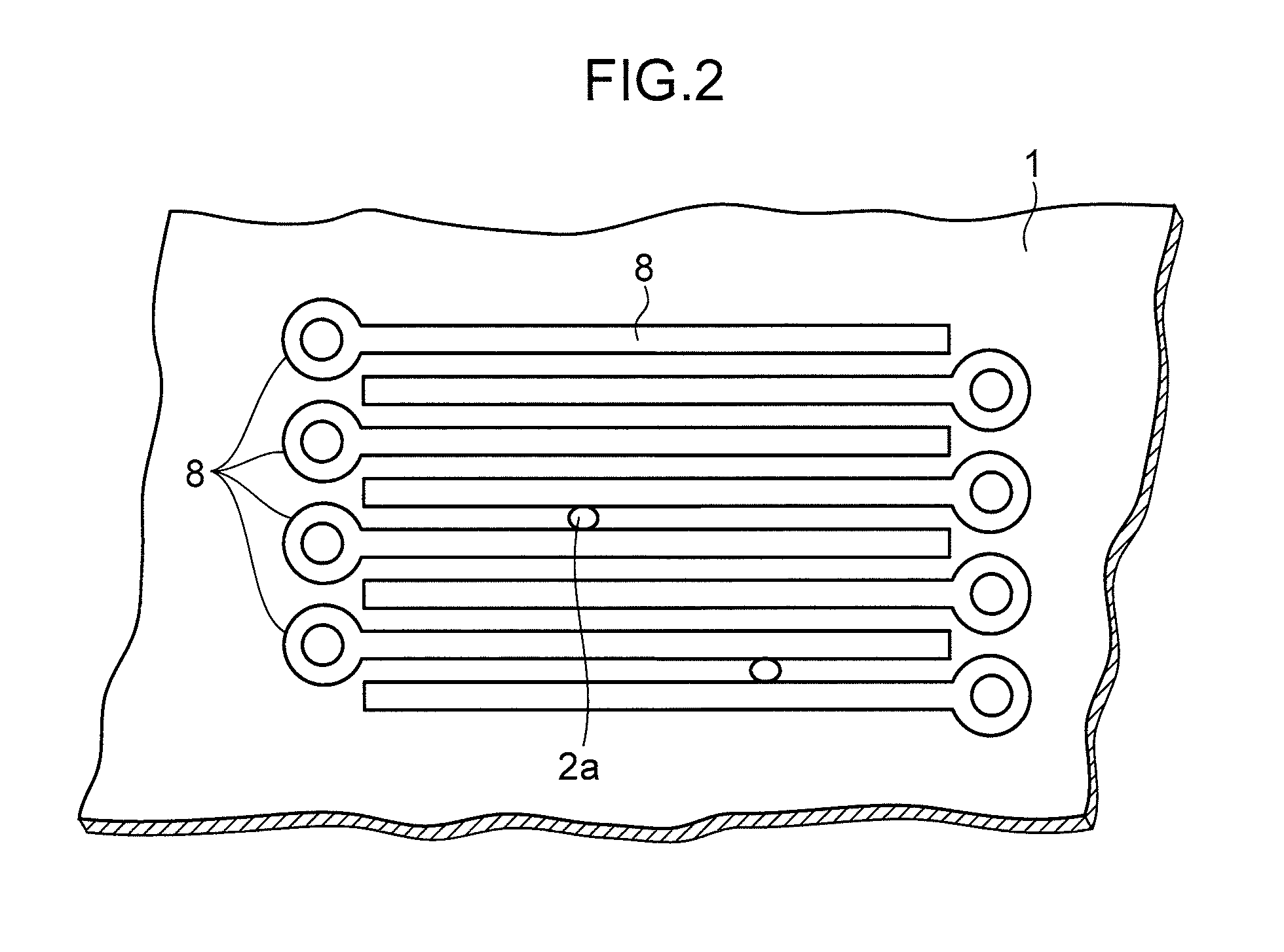

A conductive pattern film substrate and manufacturing method for combining two anisotropic materials, namely a patterned body and a film layer, without assistance from an intermediate layer. The method includes producing a thermal spraying source for performing a heating operation on a film material to prepare the film material for thermal spraying or semi-thermal spraying and thereby decompose the film material into film particles; and spraying the film particles to a pattern layer disposed on the body and having the pattern by the thermal spraying source to form the film layer having the film particle on the pattern layer, thereby enabling the body to embody electrical characteristics of the pattern.

Owner:CHANG JACKY +6

Method of producing circuit board, and circuit board obtained using the manufacturing method

One aspect of the present invention resides in a method of producing a circuit board, including a film-forming step of forming a resin film on a surface of an insulative substrate; a circuit pattern-forming step of forming a circuit pattern portion by forming a recessed portion having a depth equal to or greater than a thickness of the resin film, with an outer surface of the resin film serving as a reference; a catalyst-depositing step of depositing a plating catalyst or a precursor thereof on a surface of the circuit pattern portion and a surface of the resin film; a film-separating step of removing the resin film from the insulative substrate; and a plating step of forming an electroless plating film only in a region where the plating catalyst or the precursor thereof remains after the resin film is separated.

Owner:PANASONIC CORP

Wireless telemetry electronic circuit board for high temperature environments

InactiveUS20120009056A1Electric signal transmission systemsSemiconductor/solid-state device detailsActive componentCentrifugal force

A circuit assembly (34) resistant to high-temperature and high g centrifugal force is disclosed. A printed circuit board (42) is first fabricated from alumina and has conductive traces of said circuit formed thereon by the use of a thick film gold paste.Active and passive components of the circuit assembly are attached to the printed circuit board by means of gold powder diffused under high temperature. Gold wire is used for bonding between the circuit traces and the active components in order to complete the circuit assembly (34). Also, a method for manufacturing a circuit assembly resistant to elevated temperature is disclosed.

Owner:SIEMENS ENERGY INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com