Surface treatment device and surface treatment method for electrolytic cell flow field material

The technology of a surface treatment device and an electrolytic cell, which is applied to the electrolysis process, electrolysis components, cells, etc., can solve the problems that the treatment process is not automated and batched, the treatment process is complicated, the cost is increased, and the cost is low, and the operation is simple and convenient. , to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

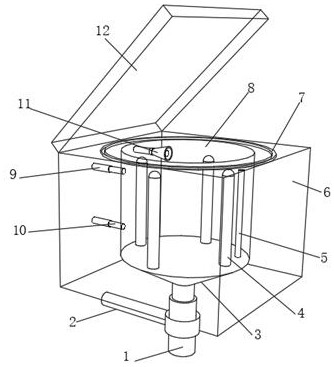

[0036] A surface treatment device for electrolyzer flow field materials, such as figure 1As shown, it includes a housing 6, the housing 6 is provided with an inner cylinder 8, and the outer wall of the housing 6 near the top of the inner cylinder 8 is provided with a sealing groove 7, and the outer wall on one side of the top of the housing 6 is connected with a top cover 12 through a hinge, and the back of the housing 6 The outer wall is respectively provided with an air inlet 9 and an air outlet 10, and the inner wall of the air inlet 9 and the air outlet 10 is threadedly connected with a conduit, and the inner wall of the bottom circumference of the inner cylinder 8 is connected with equidistantly distributed heating pipes 4 by bolts. The temperature sensor 5 is fixed on the inner wall of the bottom of the cylinder 8 by bolts, the outer wall of the bottom of the inner cylinder 8 is welded with a conical base 3, and the outer wall of the bottom end of the conical base 3 is co...

Embodiment 2

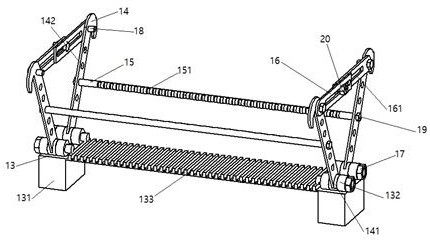

[0041] A surface treatment device for the flow field material of the electrolytic cell is also used for the fixture of the flow field material of the electrolytic cell, such as figure 2 As shown, it includes a fixed base 13, the outer walls of the two sides of the bottom of the fixed base 13 are welded with pads 131, and the top outer walls of the two pads 131 are respectively welded with two fixed rings 132, and each fixed ring 132 is rotatably connected. Rotating cylinder 141 is arranged, and the peripheral outer wall of each rotating cylinder 141 is all rotatably connected with side connecting plate 14, between each fixed ring 132 and rotating cylinder 141 are connected by positioning screw 17, every two side connecting plates 14 opposite sides The outer walls are all connected with side limiting plates 16 through positioning pins 18, and each side limiting plate 16 has a limiting groove 161 on one side of the outer wall, and every two limiting grooves 161 have the same lim...

Embodiment 3

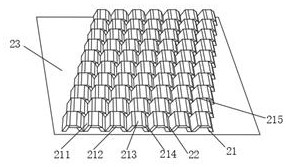

[0046] A surface treatment device for the flow field material of the electrolytic cell, which also uses the flow field of the electrolytic cell for electrolysis of water, such as Figure 3-4 As shown, the flow device 21 and the air flow device 22 are arranged alternately from left to right, and each flow device 21 includes a left side 211, a front side 212, an upper side 213, a right side 214 and a back side 215, and the bottom of the left side 211 and the right side 214 Share the same bottom surface 23, and the bottom surface 23 is coplanar with the electrode, the front surface 212 is higher than the bottom surface 23, and the height of the rear surface 215 from the bottom surface 23 is greater than the height of the front surface 212 from the bottom surface 23, and the left surface 211 and the right surface 214 are formed by the bottom surface 23. The angle is between 0° and 180°, and the air diffuser 22 is formed by the area between the right surface 214 and the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com