Side blowing device capable of controlling temperature sectionally

A segmented temperature control and side blowing technology, which is applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve problems such as long cooling length, unreachable product indicators, and abnormal fiber process, etc., to achieve cooling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

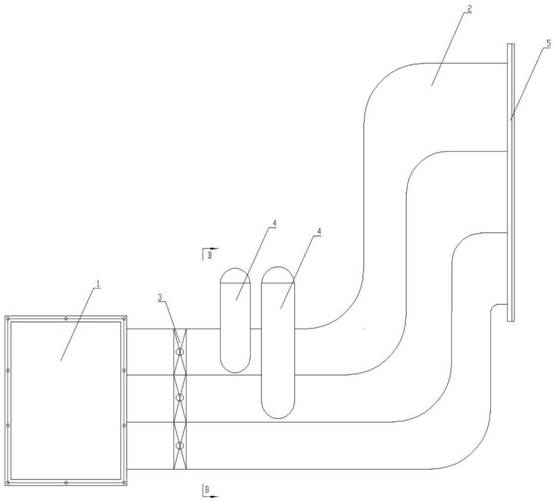

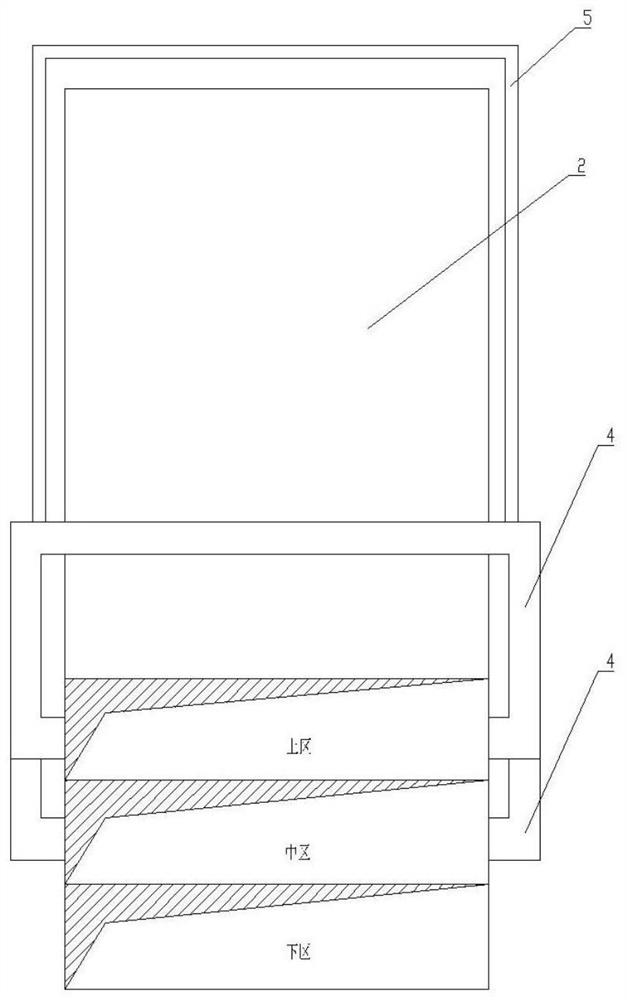

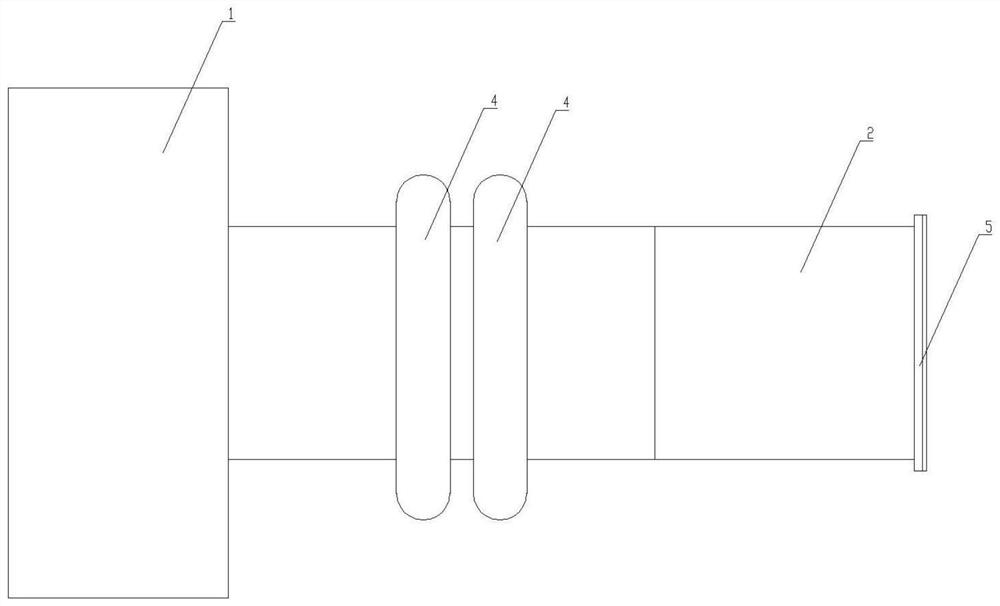

[0020] exist Figure 1 to Figure 3 In the schematic diagram of the device of the present invention shown, one side of the static pressure box 1 has a hole, and the hole is connected to the inlet end of the side blowing flow channel 2 through a flange, and the air-conditioning air is sent into the air after being stabilized by the static pressure box 1. The side blowing channel 2 ensures the stability of the wind pressure. The interior of the air flow channel 2 is divided into the upper area 2.1, the middle area 2.2, and the lower area 2.3 through the partition in the longitudinal direction, corresponding to the three areas in the longitudinal direction of the side blower outlet; The wind speed of each zone can be adjusted individually. The surface condensers 4 are respectively arranged in the upper area 2.1 and the middle area 2.2 of the air flow channel 2, and the surface condensers 4 are arranged between the air volume regulating valve 3 and the side blower window 5, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com