Closed self-circulation burn wound cooling and drying device

A technology of cooling, drying and self-circulation, which is applied in the directions of heating appliances for treatment treatment, cooling appliances for treatment treatment, gas treatment, etc. It is beneficial to wound healing, has a wide range of adaptation, and is easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

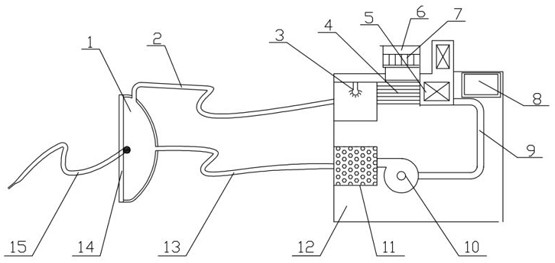

[0023] As shown in the drawings, the present invention includes a transparent cover 1 arranged outside the casing 12, a return air duct 2, a blowpipe 13, a sealing ring 14 and an elastic band 15, and a sterilizing device 3 arranged in the casing 12, Cooler 4, dehumidifier 5, fan 6, heat sink 7, power controller 8, connecting pipe 9, fan 10 and activated carbon adsorption box 11;

[0024] The transparent cover 1 is sequentially connected to the air return pipe 2, the sterilizing device 3, the cooler 4, the dehumidifier 5, the connecting pipe 9, the fan 10, the activated carbon adsorption box 11 and the blowing pipe 13, and the end of the blowing pipe 13 is connected back to the air blowing pipe 13. The transparent cover 1 is used to form a closed air self-circulation cooling drying channel;

[0025] The upper part of the cooler 4 is provided with the heat sink 7 and the fan 6, and the power controller 8 is in communication with the cooler 4, the fan 6 and the blower fan 10; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com