Inhaul cable body with fireproof shell and manufacturing method of inhaul cable body

A technology for cables and fireproof coatings, applied to bridge parts, bridge materials, bridges, etc., can solve problems such as accelerating fire spread, accelerating internal steel wire heating, and affecting steel wire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

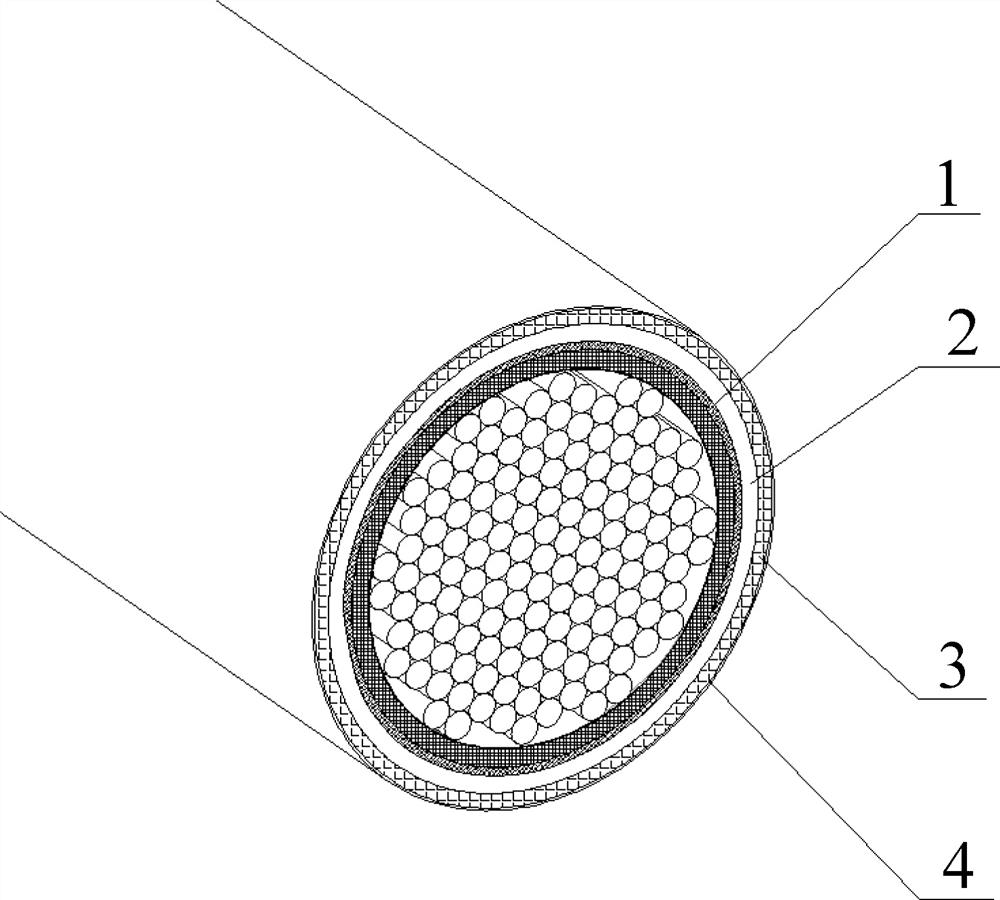

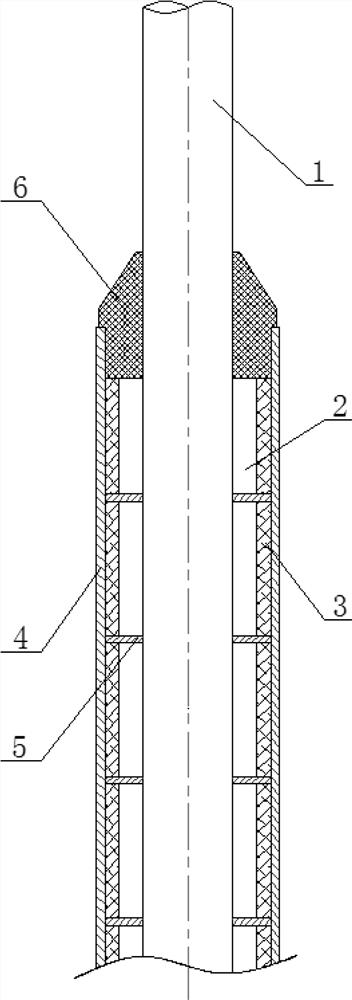

[0028] A cable body with a fireproof casing, comprising a cable body 1, a fireproof coating 3, a protective sleeve 4, a partition 5 and a gasket 6, such as figure 1 and figure 2 As shown, the specific structure is:

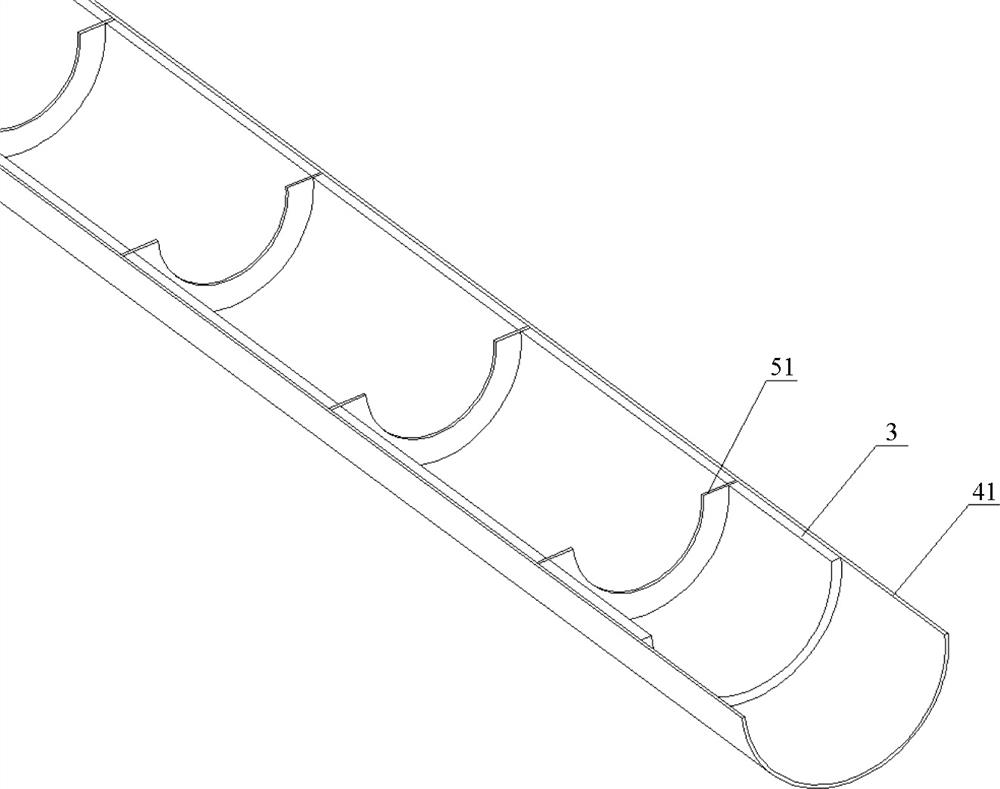

[0029] The partitions 5 are ring-shaped, and there are at least three partitions. The outer diameter of the partitions 5 matches the inner diameter of the protective sleeve 4. Each partition 5 is fixed on the inner side wall of the protective sleeve 4 by spot welding. The partitions 5 are all perpendicular to the central axis of the protective casing 4, and the intervals between two adjacent partitions 5 are equal; the inner wall of the protective casing 4 is painted with a fireproof paint 3, and the cable body 1 is pulled from the protective casing. One end of 4 penetrates through the central through hole of each partition 5 in turn and then passes out from the other end of the protective sleeve 4, and the expansion buffer layer 2 is formed between the outer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com